Method for detecting overall dimensions of panel-type furniture based linear scanning laser

A technology for panel furniture and outline dimensions, applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems such as the inability to measure the size, shape and quality of objects at the same time, the inability to quickly and reliably detect high-resolution objects, and difficulties in implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

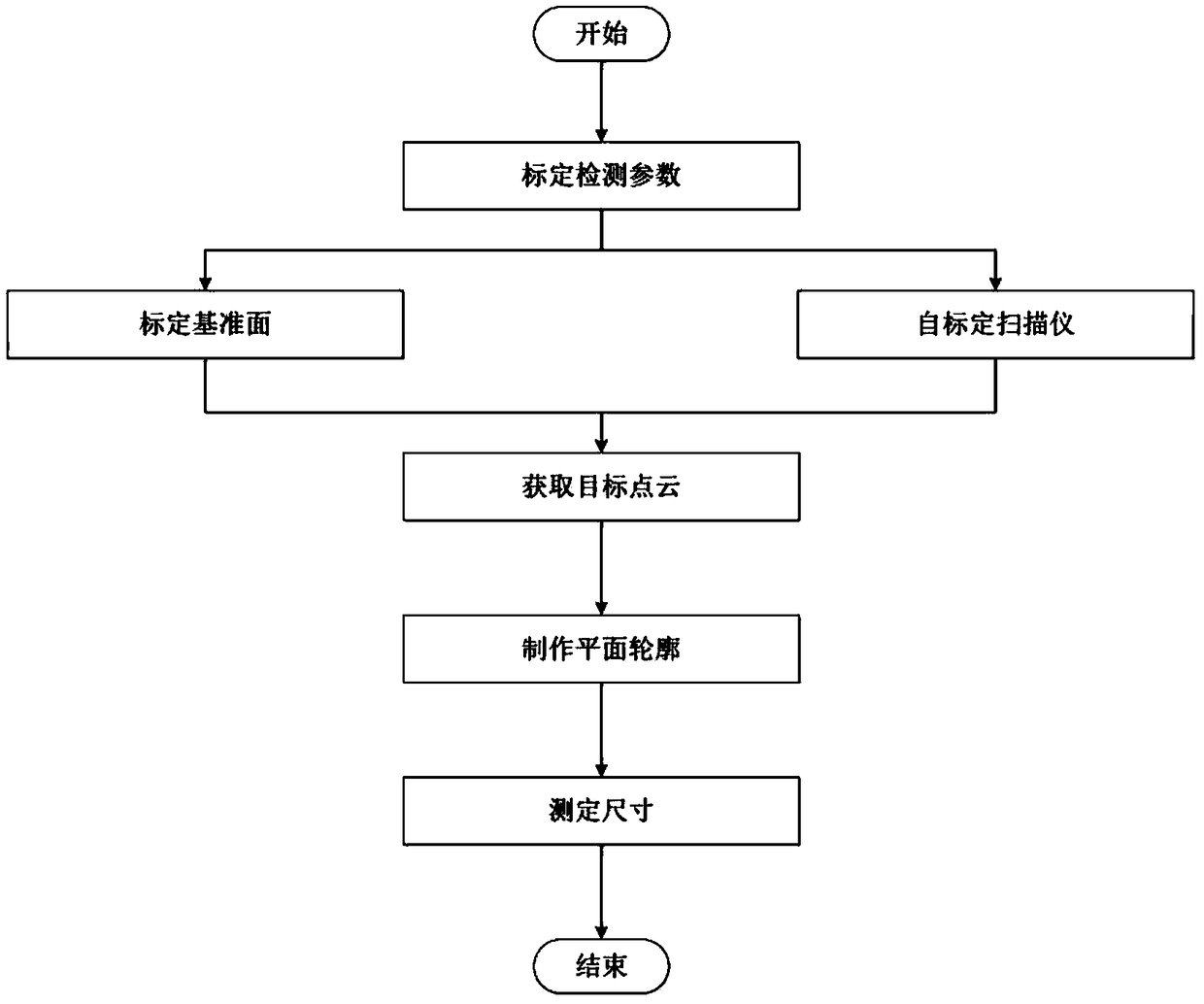

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0034] A line-scanning laser-based detection system for the outline size of panel furniture in this embodiment, such as figure 1 As shown, it specifically includes the following steps:

[0035] Step A: Calibrate the detection system parameters, the specific steps are as follows:

[0036] Step A1: Calibrate the reference plane;

[0037] Step A2: Self-calibration of the scanner to obtain parameters such as resolution;

[0038] Step B: Scan the plate to be tested to obtain a point cloud. The specific steps are as follows:

[0039] Step B1: scanning and collecting the spatial three-dimensional data of the surface of the plate to be tested;

[0040] Step B2: The data obtained in B1 is filtered by median filtering to obtain the target point cloud.

[0041] Step C: making a plane profile;

[0042] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com