Auxiliary device for detecting sapphire crystal bar defects

A defect detection and auxiliary device technology, which is applied in the direction of optical detection of defects/defects, can solve the problems of low detection efficiency, section edge collapse, etc., and achieve the effect of improving detection efficiency and avoiding edge collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

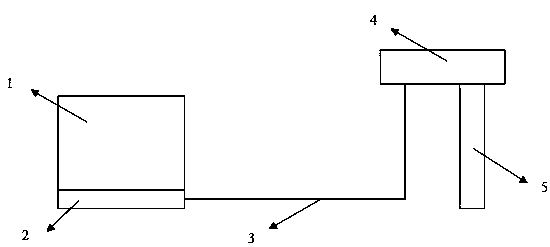

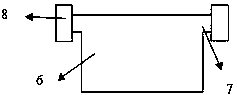

[0023] Example 1: Combining Figure 2-4 , the present embodiment is a support-type rotating device for driving crystal ingots, the structure mainly includes: a base 6 structure in the shape of a "concave", and the four corners are connected to the rolling bearing journal 7, the journal is a cylinder, and the bearing inner ring of the rolling bearing 5 can be 9 is fixed on the base, and the rolling bearing outer ring 8 is rotatable to drive the ingot to rotate the tooling to install a pressure sensor, and the sensor is connected to the laser through an external circuit. The length of the support type driven crystal ingot rotating tool base is 180mm, the width is 100mm, the rolling bearing journal is cylindrical, and the length is 12mm longer than the width of the rolling bearing inner ring; the up and down movement range of the bracket is 120mm, and the height of the laser beam is higher than that of the driving crystal ingot rotating tooling 70mm.

Embodiment 2

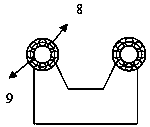

[0024] Example 2: Combining Figure 5-7 , the present embodiment is a drum-type rotary device for driving crystal ingots, and its structure mainly includes: a base 10 in a "concave" shape, and a long cylindrical roller bearing 11 connected to the upper sides of the "concave"-shaped base Ring 13, and the outer ring 12 of the bearing can be rotated to drive the ingot rotating tool to install a pressure sensor, which is connected to the laser through an external circuit. The length of the base of the roller-type driven ingot rotating tooling is 110mm, the width is 100mm, and the length of the long cylindrical roller bearing is 90mm; the up and down movement range of the bracket is 140mm, and the height of the laser beam is 65mm higher than that of the driving ingot rotating tooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com