Liquid crystal display device and turning film for liquid crystal display device

一种液晶显示装置、转向膜的技术,应用在转向膜领域,能够解决颜色不均、亮度不均等问题,达到抑制亮度不均、抑制颜色不均的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0038] [Liquid crystal display device]

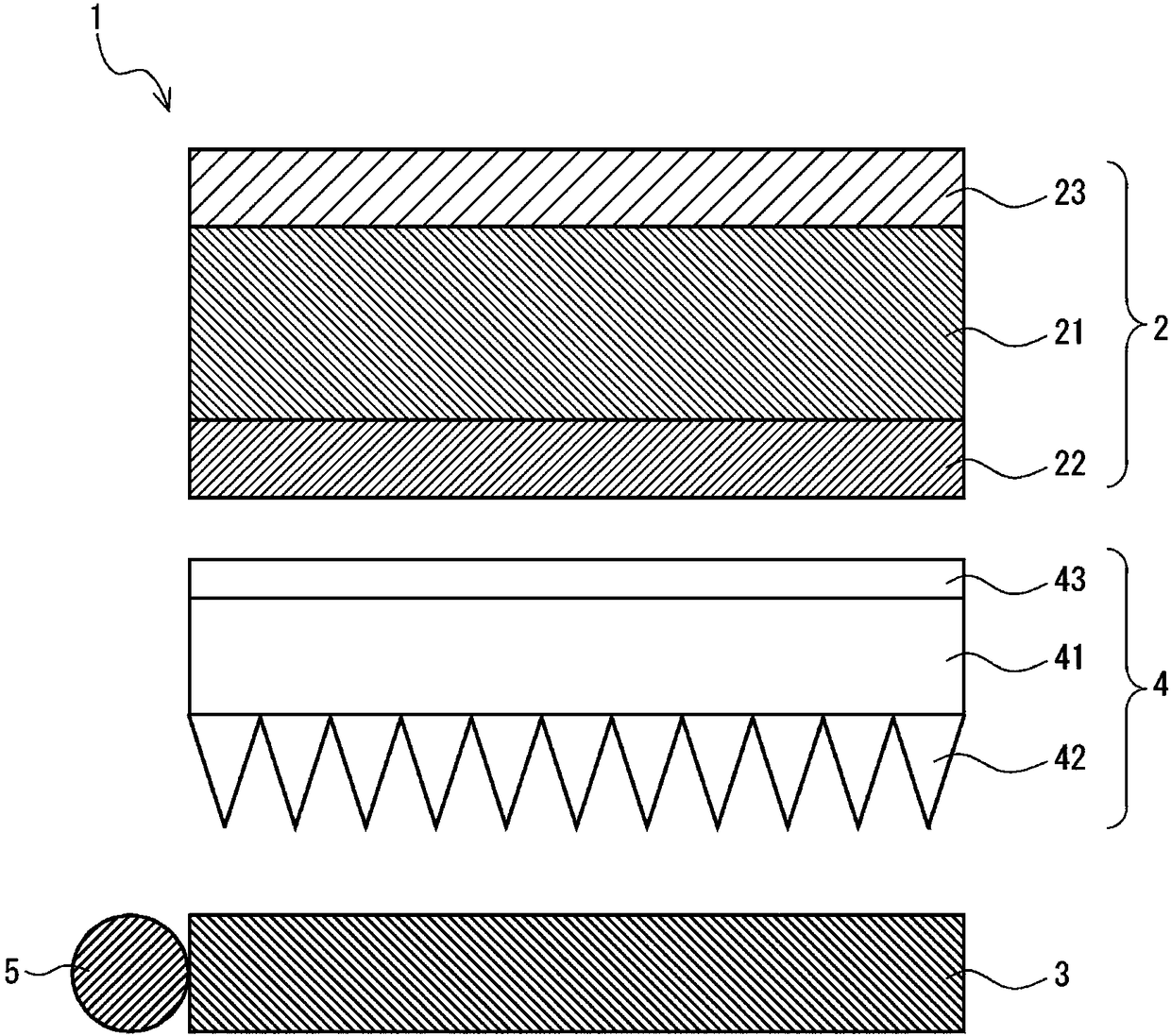

[0039] figure 1 The liquid crystal display device 1 comprises: a liquid crystal panel 2; a light guide plate (light guide film 3), which is overlapped on the back side of the liquid crystal panel 2, and guides the light incident from the end surface to the surface side; one or more LED light sources 5, It is arranged along the end surface of the light guide film 3 ; and the turning film 4 is overlapped between the liquid crystal panel 2 and the light guide film 3 . In addition, the light guide film 3 and the turning film 4 are transparent because light is to be transmitted therethrough. In addition, the liquid crystal display device 1 further includes a reflector that is superimposed on the back side of the light guide film 3 and reflects light incident from the front side toward the front side (not shown).

[0040]

[0041] The liquid crystal panel 2 has: a liquid crystal cell 21; a back side polarizing plate 22 disposed on the fac...

no. 2 approach

[0068] [Liquid crystal display device]

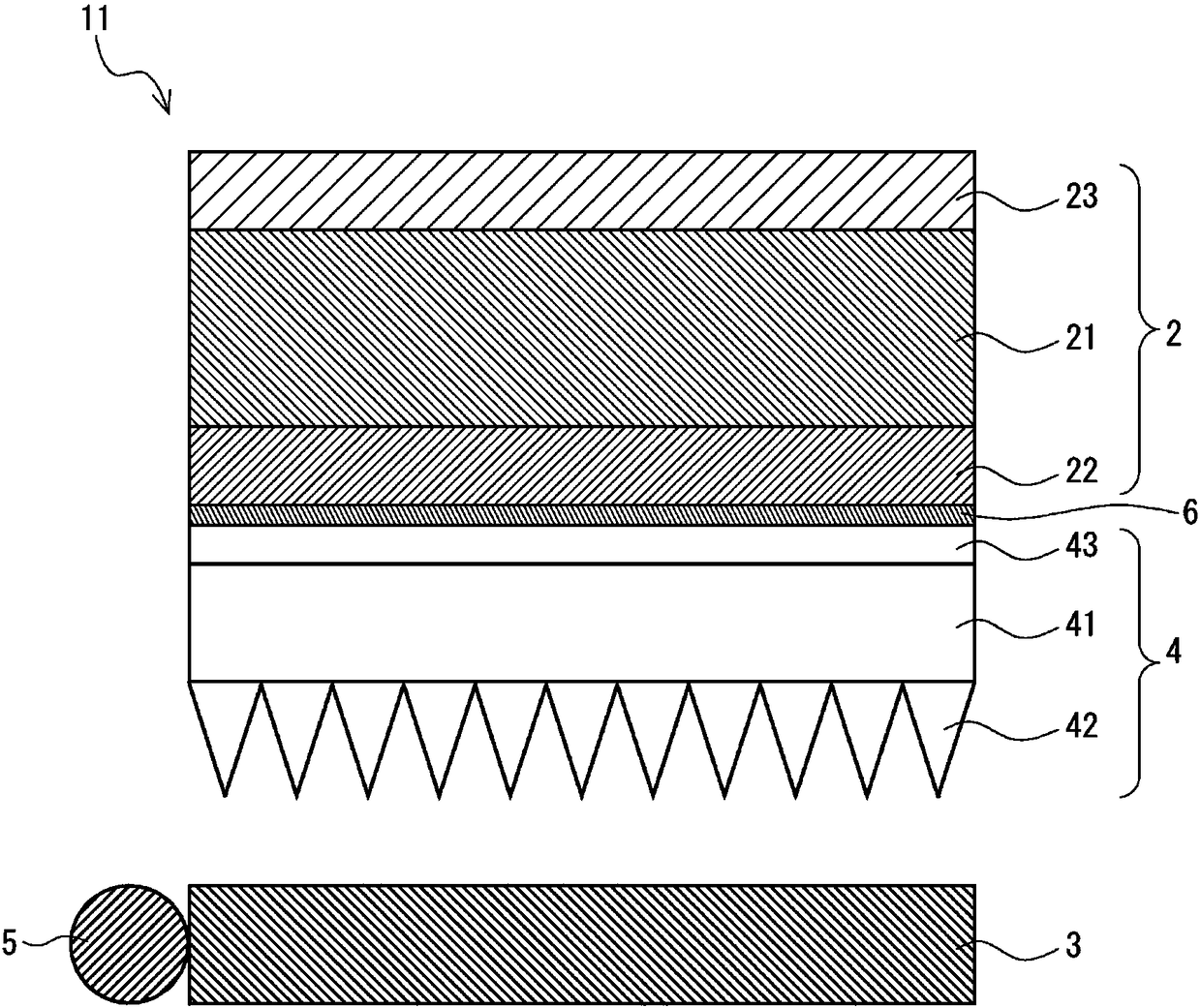

[0069] figure 2 The liquid crystal display device 11 comprises: a liquid crystal panel 2; a light guide plate (light guide film 3), which overlaps the back side of the liquid crystal panel 2, and guides the light incident from the end surface to the surface side; one or more LED light sources 5, It is arranged along the end surface of the light guide film 3 ; and the turning film 4 is overlapped between the liquid crystal panel 2 and the light guide film 3 . In addition, the liquid crystal display device 11 includes an adhesive layer arranged between the liquid crystal panel 2 and the turning film 4 . In addition to having the bonding layer 6, the liquid crystal display device 11 and figure 1 The configuration of the liquid crystal display device 1 is the same. Therefore, only the bonding layer 6 will be described below.

[0070] (junction layer)

[0071] The bonding layer 6 bonds the turning film 4 and other members laminated on ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com