Sodion battery manufacture method

A sodium ion battery, sodium ion technology, applied in electrode manufacturing, battery electrodes, secondary batteries, etc., can solve the problems of high cost of metal oxides, low full battery voltage, and high voltage, and achieve the effect of improving cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with specific embodiment, the present invention is further elaborated and illustrated:

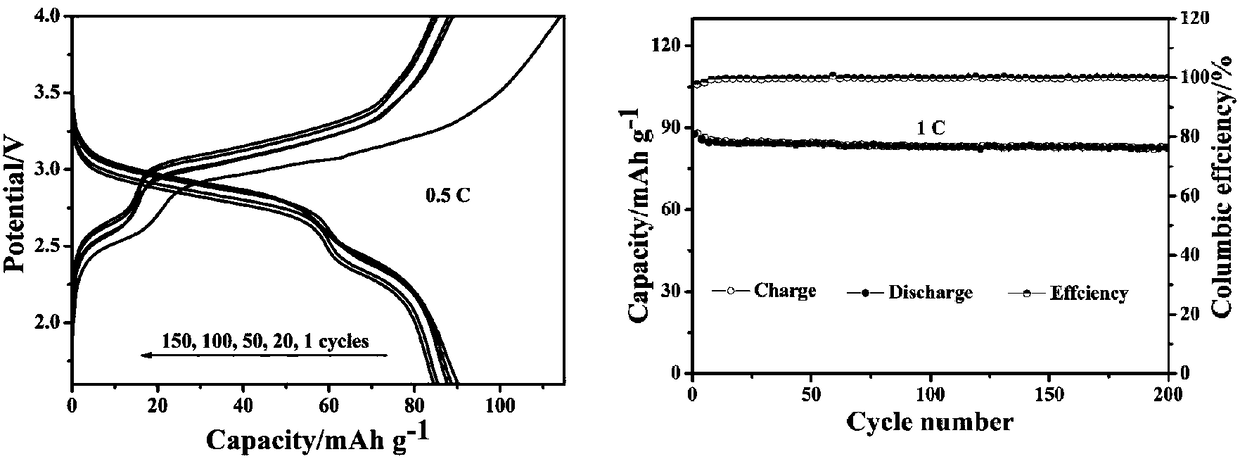

[0026] Weigh 80mg Na 3.64 Fe 2.18 (P 2 o 7 ) 2 , 10mg acetylene black conductive agent, 10mgPVDF binding agent, get 400 microliters of 1-methyl-2-pyrrolidone (NMP) as a solvent and grind it in an agate mortar for 20 minutes to obtain a black viscous positive electrode slurry. The positive electrode slurry was evenly spread on the aluminum foil, dried under vacuum at 120° C. for 12 hours, and then the aluminum foil was cut into a circle with a diameter of 19 mm by a tablet press to obtain a positive electrode sheet.

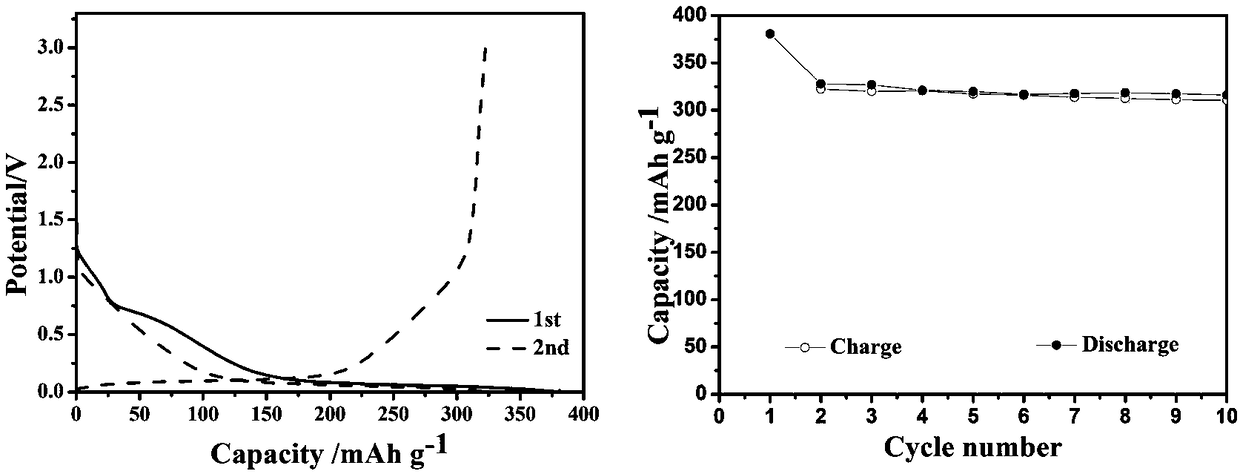

[0027] Weigh 80 mg of hard carbon, 10 mg of acetylene black conductive agent, 10 mg of PVDF binder, and take 400 microliters of 1-methyl-2-pyrrolidone (NMP) as a solvent, and grind for 20 minutes in an agate mortar to obtain a black sticky Negative electrode slurry, apply the negative electrode slurry evenly on the aluminum foil with a scraper,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com