Battery temperature management system

A technology for managing system and battery temperature, applied to secondary batteries, battery/fuel cell control devices, circuits, etc., can solve problems such as accelerating internal chemical reactions, overcharging, battery safety hazards, etc., to improve utilization efficiency and use The effect of life and rapid heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

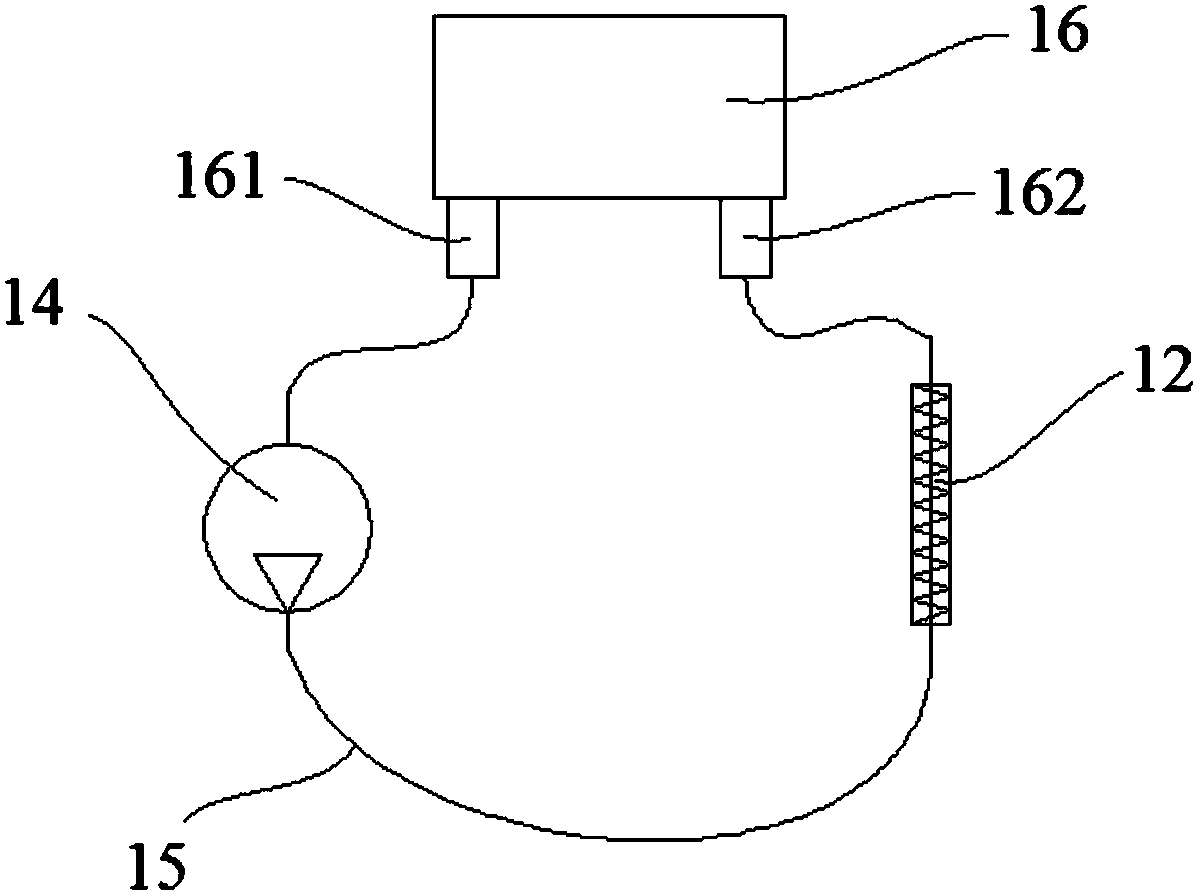

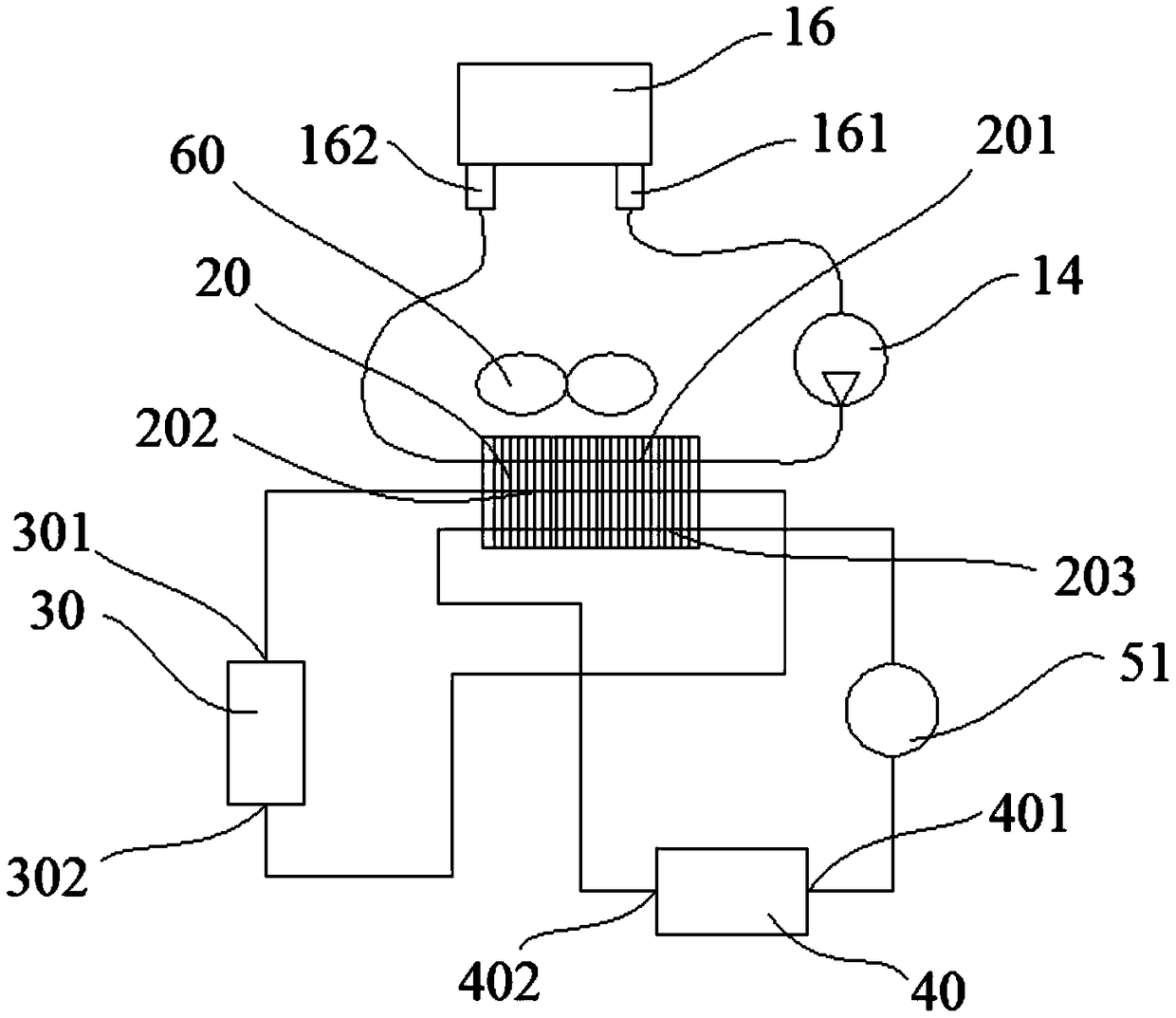

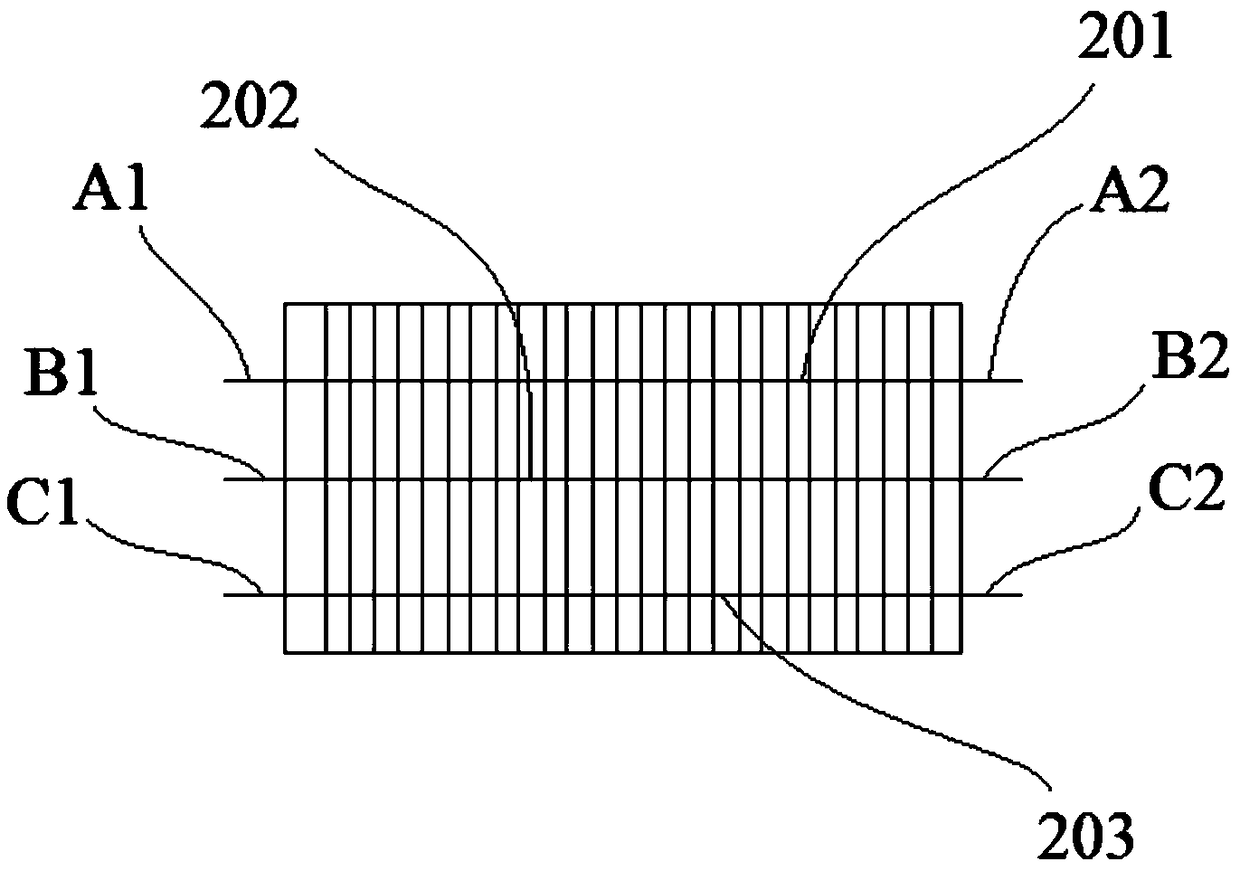

[0045] figure 2 It is a schematic diagram of the connection of the battery temperature management system of this embodiment, from figure 2 It can be seen from the figure that the water outlet 161 of the battery pack box 16 is connected with the first water pump 14, the heat exchange element 20 and the water inlet 162 of the battery pack box 16 in turn through the pipe body. Under the action of the first water pump 14, the internal The natural water can be circulated between the battery case 16 and the heat exchange element 20, thereby constituting the first circulation. Preferably, the heat exchanging element 20 is a heat exchanger, which is a commonly used heat exchanging element with various specifications, which can be selected according to specific implementation conditions. Here, the heat exchange element 20 includes at least 3 channels, wherein the first channel 201 is connected to the first cycle.

[0046] image 3 A structural diagram of the heat exchange element ...

Embodiment 2

[0053] In the second embodiment, as Figure 4a As shown, the cooling module 30' includes a compressor 31 and a condenser 32, and the port B1 of the second channel of the heat exchange element 20 is connected with the compressor 31, the condenser 32 and the port B2 through a pipe in turn, and the compressor 31 Under the action, the refrigerant coming out of the compressor 31 passes through the condenser 32 and the second channel of the heat exchange element 20 in sequence before entering the compressor 31 .

[0054] Compressor 31 and condenser 32 are commonly used refrigeration elements, which are contained in conventional vehicles. Therefore, the cooling module can be specially equipped with compressors and condensers, or the existing ones in the vehicle can be used. compressor and condenser, thereby reducing the cost of cooling modules.

[0055] In order to control the circulation of the refrigerant more flexibly, preferably, a first expansion valve 33 is provided between th...

Embodiment 3

[0057] Different from Embodiment 1 and Embodiment 2, in this embodiment, the battery pack temperature management system shares a set of cooling modules with the air-conditioning system in the vehicle compartment, such as Figure 5 As shown, the first end 301' of the cooling module 30' is not only connected to the B1 end of the heat exchange element 20, but also connected to one end of the evaporator 35 through a tube, and the other end of the evaporator 35 is connected to the pressure sensor 34 and the first end of the evaporator 35. The common end 37 of the expansion valve 33 is connected through a pipe. Of course, the other end of the evaporator 35 can also be directly connected with the second end 302' of the cooling module 30' through a pipe. In order to be able to control the cooling state of the air conditioning system, preferably, a second expansion valve 36 is provided between the evaporator 35 and the common port 37 . In this way, under the action of the cooling modul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com