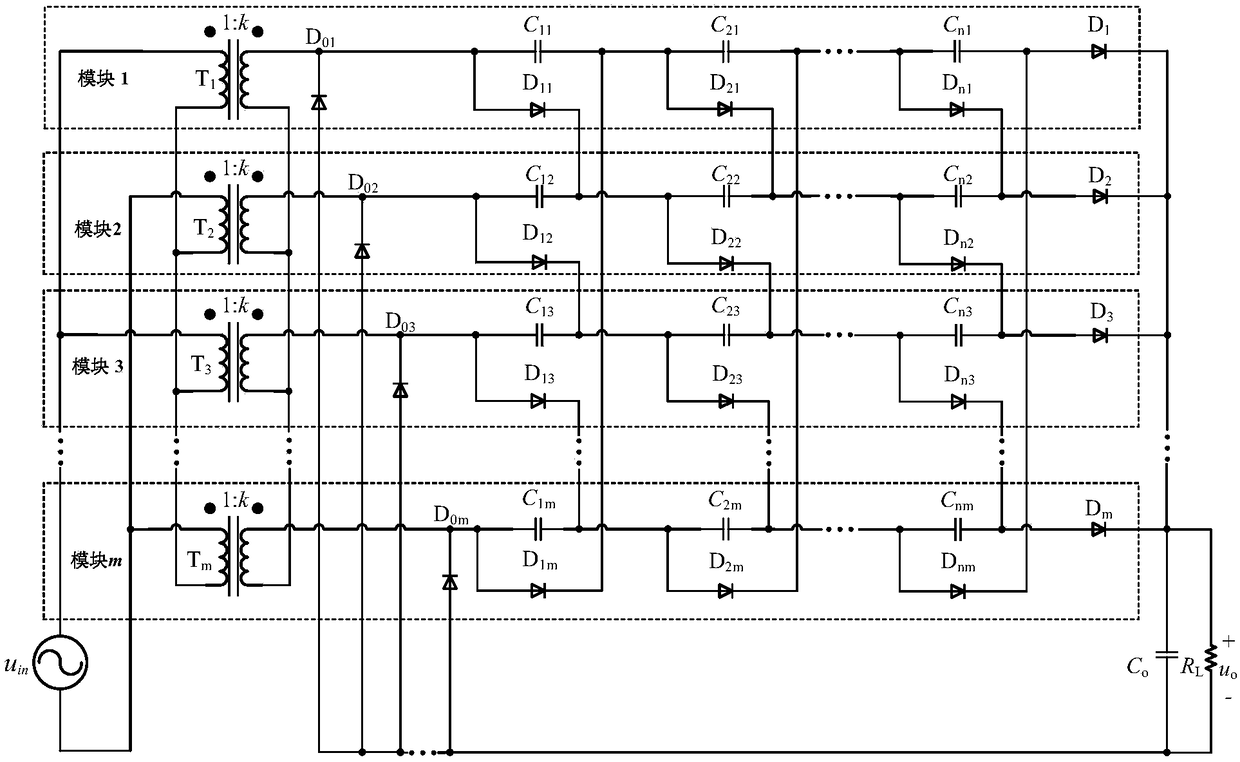

Modular high-boost high-capacity isolation type rectifier circuit

A rectifier circuit and high-boost technology, applied in the direction of irreversible AC power input conversion to DC power output, etc., can solve problems such as difficult current sharing, achieve increased capacity, easy control of circuit heat dissipation, and reduce circuit complexity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

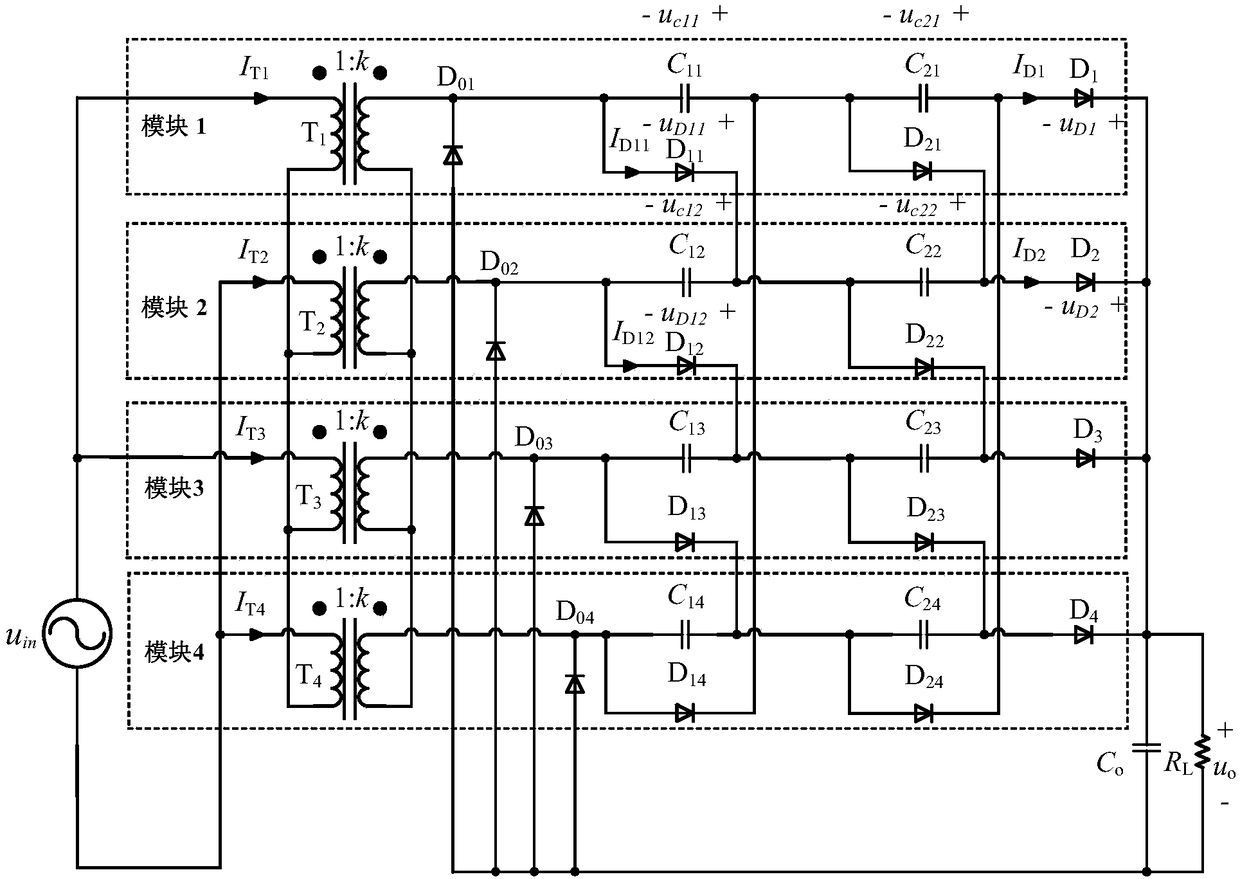

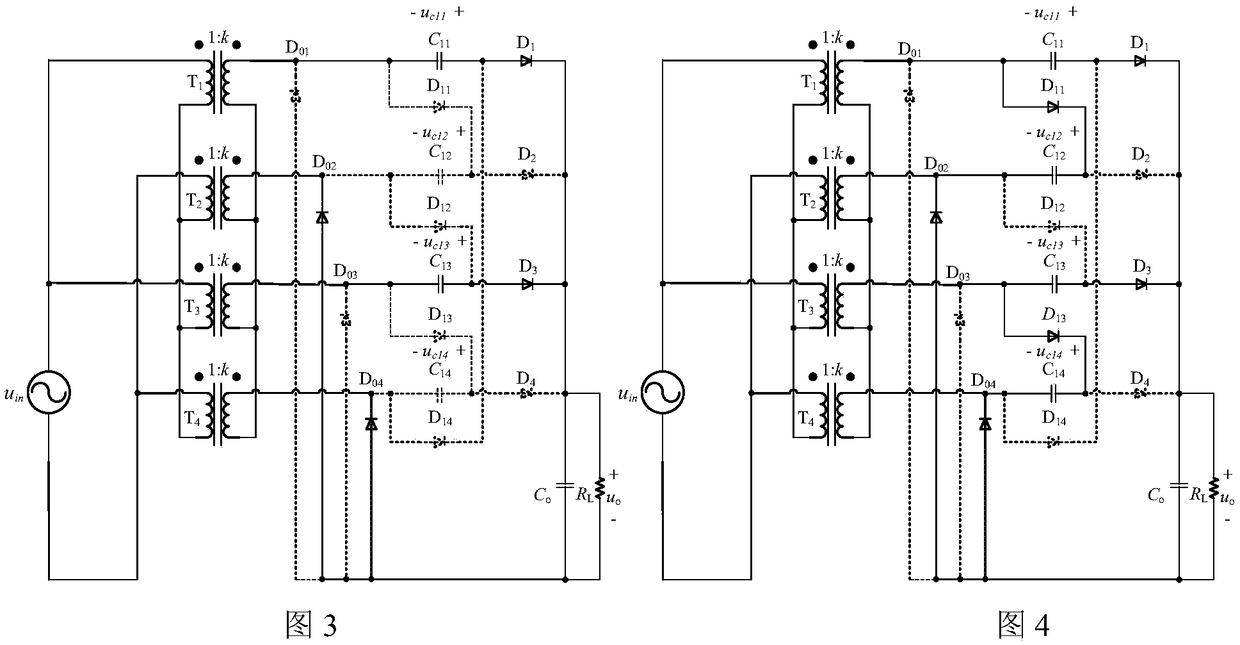

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0035] Such as figure 2 As shown, a 4-module self-balanced high-boost large-capacity isolated rectifier circuit, which includes an AC input power supply, 4 modules, and an output filter capacitor C 0 , 1 load R L . Each of these modules contains a transformer with a transformation ratio of 1:k, 4 diodes, and 2 capacitors. In this way there are 4 transformers T 1 , T 2 , T 3 , T 4 , 8 capacitors C 11 、C 12 、C 13 、C 14 、C 21 、C 22 、C 23 、C 24 , 16 diodes D 1 、D 2 、D 3 、D 4 、D 101 `, D 02 、D 03 、D 04 、D 11 、D 12 、D 13 、D 14 、D 21 、D 22 、D 23 、D 24 . Among them, the connection methods of the four modules are as follows:

[0036] First module, secondary side, transformer T 1 Termination capacitor C with the same name on the secondary side 11 Left end, diode D 11 anode and diode D 01 the cathode, the capacitance C 11 The right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com