Device and method for adsorption synergizing low temperature plasma to catalyze and treat waste gas

A low-temperature plasma and catalytic treatment technology, applied in separation methods, gas treatment, chemical instruments and methods, etc., can solve problems such as limited space, poor desorption and regeneration effect of adsorbent, and treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

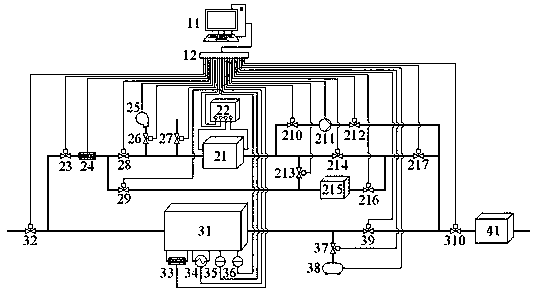

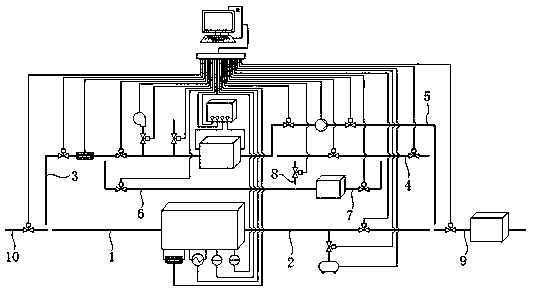

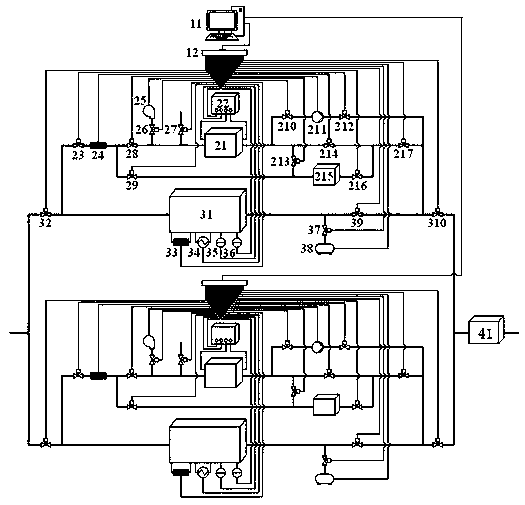

[0063] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0064] see figure 1 , figure 2 , a device for adsorbing and cooperating with low-temperature plasma catalytic treatment of exhaust gas, including an intake pipe 10, a first air pipe 1, an adsorption unit 31, a second air pipe 2, and an exhaust pipe 9 connected in sequence; the intake pipe 10 is provided with an intake switch Valve 32, the exhaust pipe 9 is provided with an exhaust switch valve 310; it also includes a plasma generation unit 21; the plasma generation unit 21 is connected to one end of the air intake pipe 10 connected to the first air pipe 1 through the third air pipe 3 Connect the exhaust pipe 9 to the end of the second air pipe 2 through the fifth air pipe 5 and the fifth on-off valve I 210, the suction compression pump mechanism 211 and the fifth on-off valve II 212 arranged in sequence on the fifth ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com