Laser transmission welding system and method

A technology of laser transmission welding and laser transmitter, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of air welding quality influence, uneven clamping force, etc., and achieve good permeability and absorption Good, guaranteed sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

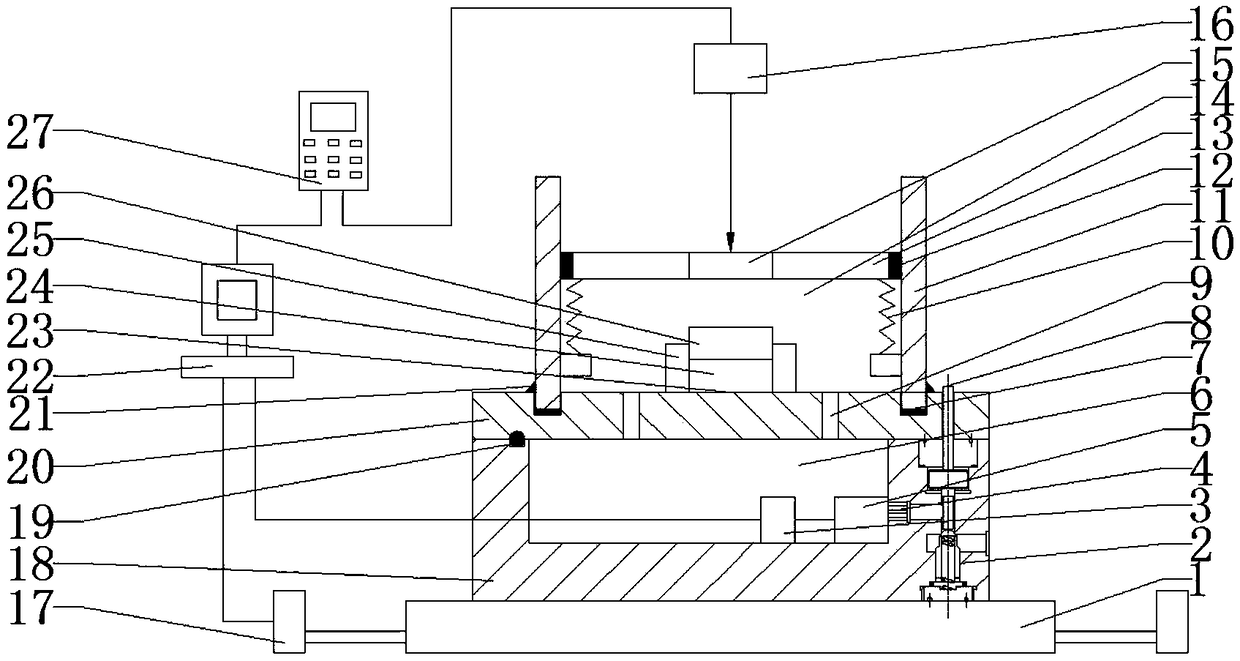

[0033] combined with figure 1 As shown, the present invention relates to a vacuum clamping device for laser transmission welding, including a vacuum clamping system and a control system.

[0034] The vacuum clamping system includes a coordinate platform 1, a clamping device and a workpiece system;

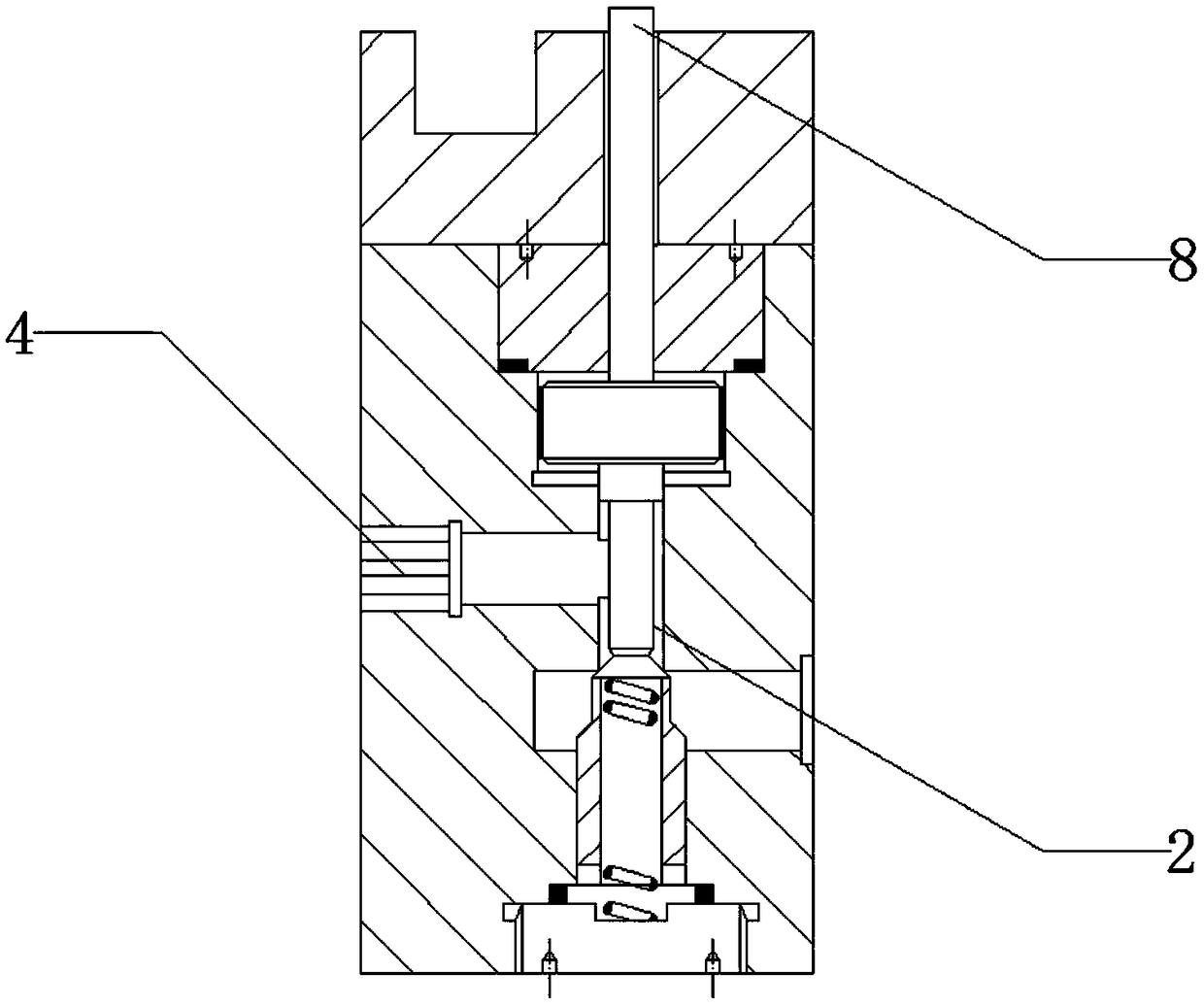

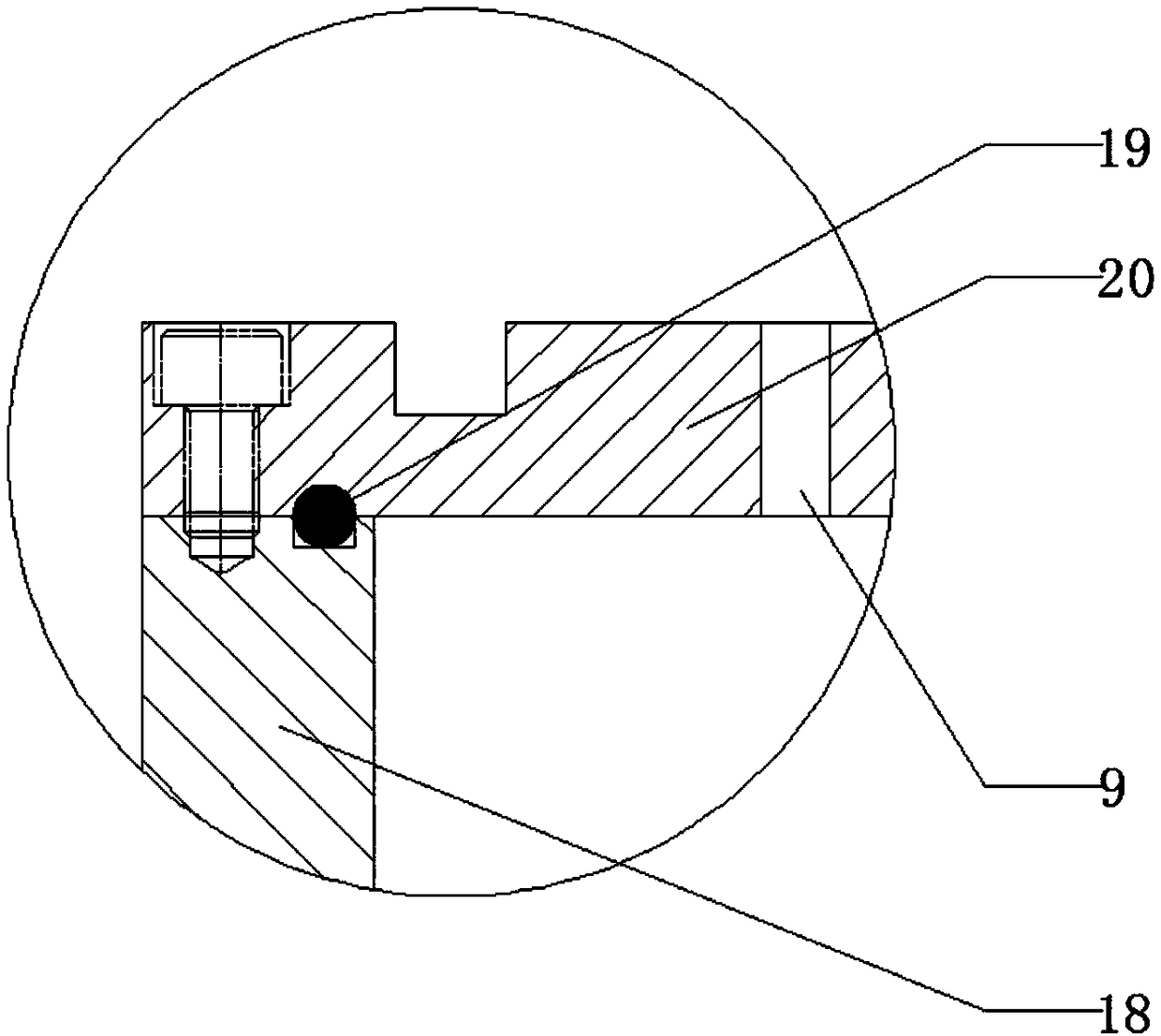

[0035] The clamping device includes a base 18, an upper baffle 20, a one-way valve 2, an exhaust pipeline 4, an air extractor 5, a gasket 7, a sealing ring 19, a sealant 21, an air extraction hole 9, a spring 10, a circular Box body 11, piston 12, piston plate 13, light-transmitting glass 15; base 18 is fixed on coordinate platform 1;

[0036]The one-way valve 2 is located on the right side of the base 18, which is used to ensure that the gas inside the clamping device can o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com