Qt-based 3D printing control system and communication method thereof

A 3D printing and control system technology, applied in manufacturing auxiliary devices, processing data acquisition/processing, additive processing, etc., can solve the problem of limited lower-level computer processors and on-chip resources, difficult monitoring of system control quantities, and data interaction capabilities Limited and other problems, to achieve excellent motion control performance, convenient equipment expansion, convenient and efficient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

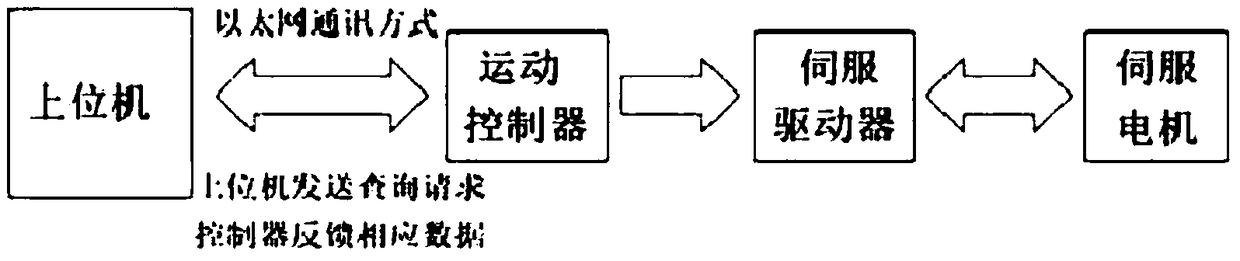

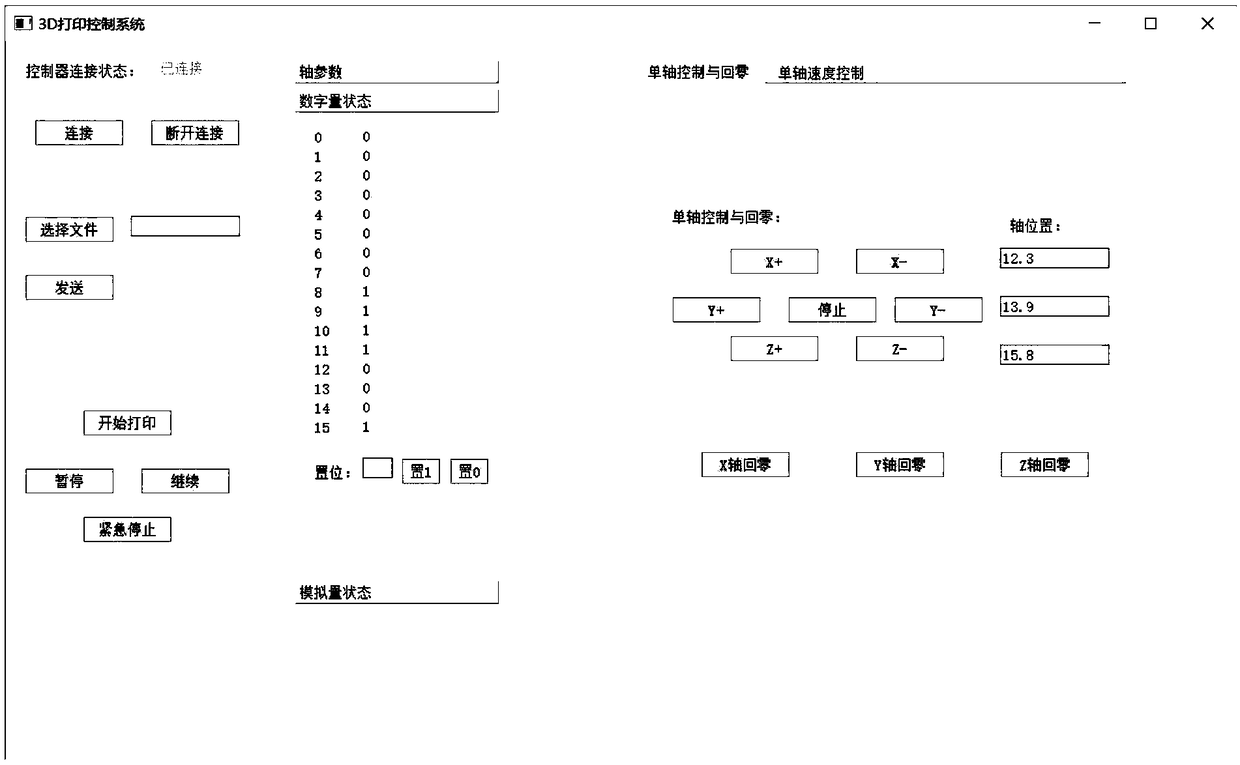

[0048] The software design in this embodiment is based on the hardware equipment. The main motion axis has four parts, including X, Y, Z and extrusion wire motor. The controller uses the differential pulse direction control mode to connect the servo or stepper of the four parts The motor driver is connected from the controller to the host computer with a network cable, open the software interface, click the connect button, and connect the driver.

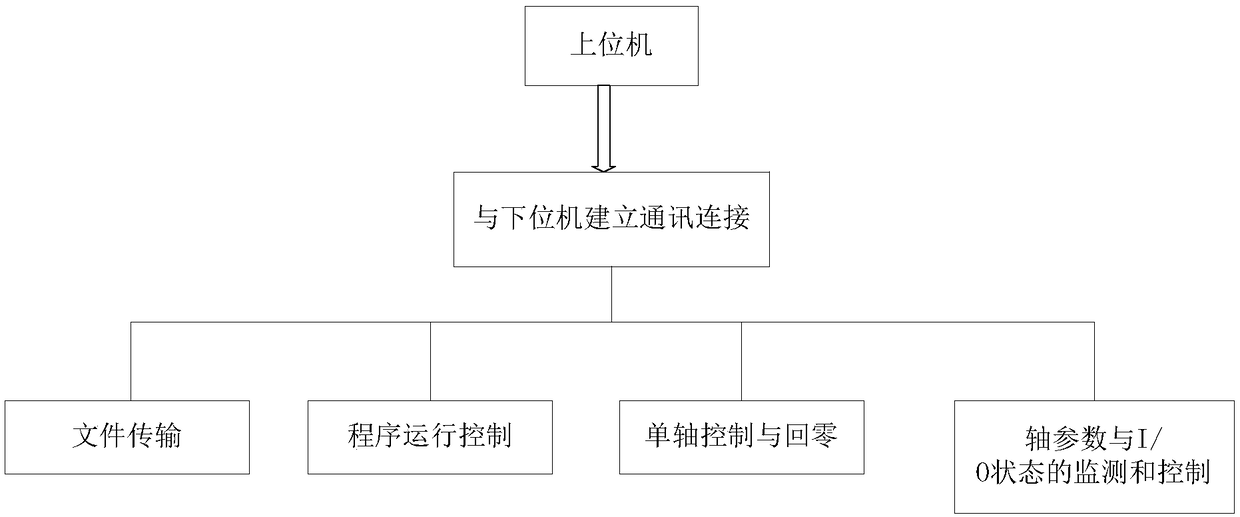

[0049] The first part: The host computer establishes a communication connection with the controller. The Trio PC Motion control package provided by TRIO can use the Qt method to export the TRIO com component, and two files will be generated, namely the TRIO control header file and source file, and these two files will be added in the project folder. Qt is an object-oriented application design framework. The programming language is basically C++. It is necessary to define a controller object in the interface file, name it pc, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com