Coal cinder powder magnesium oxysulfate cement stable recycled concrete aggregate and preparation method thereof

A technology for powdered magnesium oxysulfate cement and recycled concrete, which is applied in the field of building materials, can solve problems such as low utilization rate, and achieve the effects of convenient material selection, environmental protection, alleviation of land occupation problems, and expansion of application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

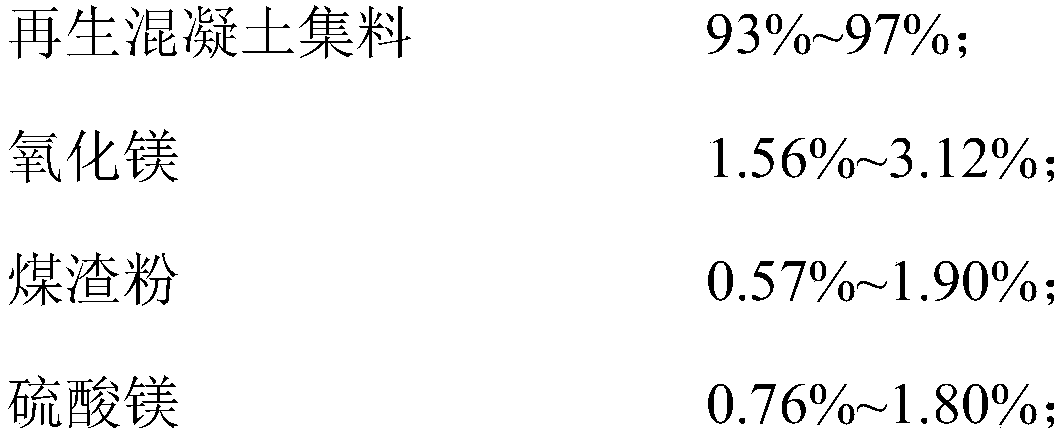

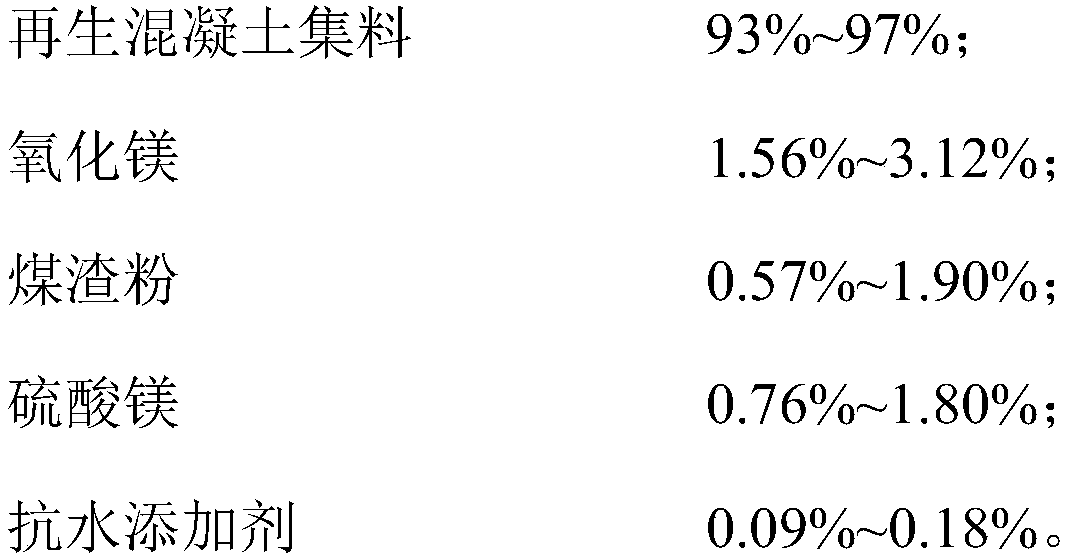

Method used

Image

Examples

Embodiment 1

[0041] First, recycled concrete aggregates were produced by the following process.

[0042] Specifically, waste cement concrete road slabs, components of demolished buildings, waste cement concrete test blocks, etc. are collected and recycled; the recycled waste concrete is sequentially crushed for the first time, ribs removed, crushed for the second time, and obtained by screening. Recycled concrete aggregates in the particle size range are required; the mass percentages of the obtained recycled concrete aggregates passing through the following sieves are shown in Table 2.

[0043] Table 2 Content of recycled concrete aggregate passing through each sieve hole

[0044]

[0045] The resulting recycled concrete aggregate had a crush value of 22.6% and an apparent density of 2.69 g / cm 3 .

[0046] The sieving results in the above Table 2 were mixed according to the mass ratio of 33.4% rice sand, 29.2% melon seed slices, 23.5% small crushed and 13.9% medium crushed to obtain ...

Embodiment 2

[0054] First, recycled concrete aggregates were produced by the following process.

[0055] Specifically, waste cement concrete road slabs, demolished building components, waste cement concrete test blocks, etc. are collected and recycled; the recycled waste concrete is sequentially crushed, ribs removed, secondary crushed, and screened to obtain all Recycled concrete aggregates in the particle size range are required; the mass percentages of the obtained recycled concrete aggregates passing through the following sieve holes are shown in Table 4.

[0056] Table 4 The content of recycled concrete aggregate passing through each sieve hole

[0057]

[0058] The resulting recycled concrete aggregate had a crush value of 24.6% and an apparent density of 2.72 g / cm 3 .

[0059] The sieving results in the above Table 4 were mixed according to the mass ratio of 35.6% rice sand, 18.7% melon seed slices, 25.6% small crushed and 20.1% medium crushed to obtain recycled concrete aggreg...

Embodiment 3

[0064] In the description of Embodiment 3, the similarities with Embodiment 1 will not be repeated here, and only the differences with Embodiment 1 will be described. The difference between embodiment 3 and embodiment 1 is that it is 2.08:0.76:1.04:0.12:96 to mix each material according to the mass ratio of magnesia, cinder powder, magnesium sulfate, anti-water additive, recycled concrete aggregate; As described in Example 1, the cinder powder magnesium oxysulfate cement stabilized recycled concrete aggregate of this example was obtained.

[0065] The performance of the cinder powder magnesium oxysulfate cement stabilized recycled concrete aggregate of this embodiment was measured by the same measuring method as in Example 1. According to the maximum dry density and optimum water content determined by the vibration test, 10.68% of the quality of the recycled concrete aggregate stabilized by cinder powder magnesium oxysulfate cement was added to the tap water for mixing, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com