Double-side digital printing method of cashmere shuttle fabric and cashmere products

A technology for digital printing and woven fabrics, applied in the field of cashmere products, can solve the problems of reducing the difficulty of inkjet printing, achieve bright colors, ensure inkjet printing effects, and the effect of complete and bright pattern colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

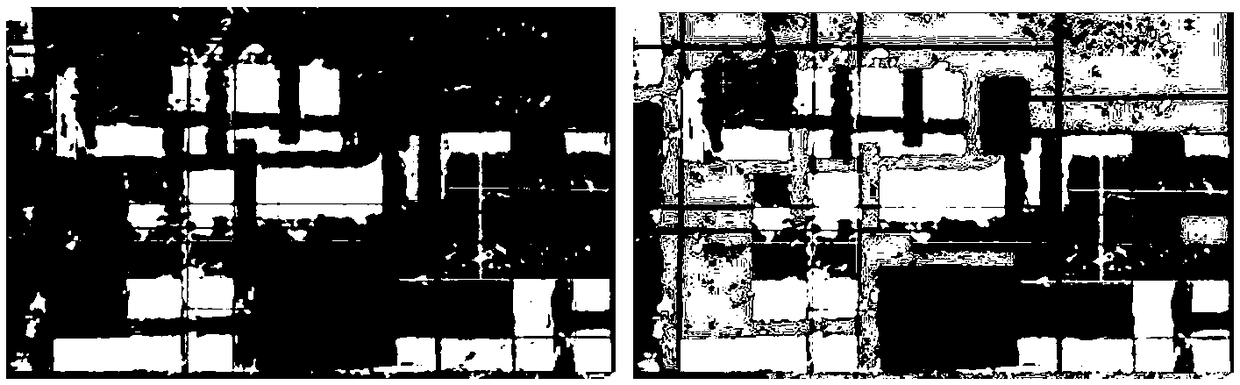

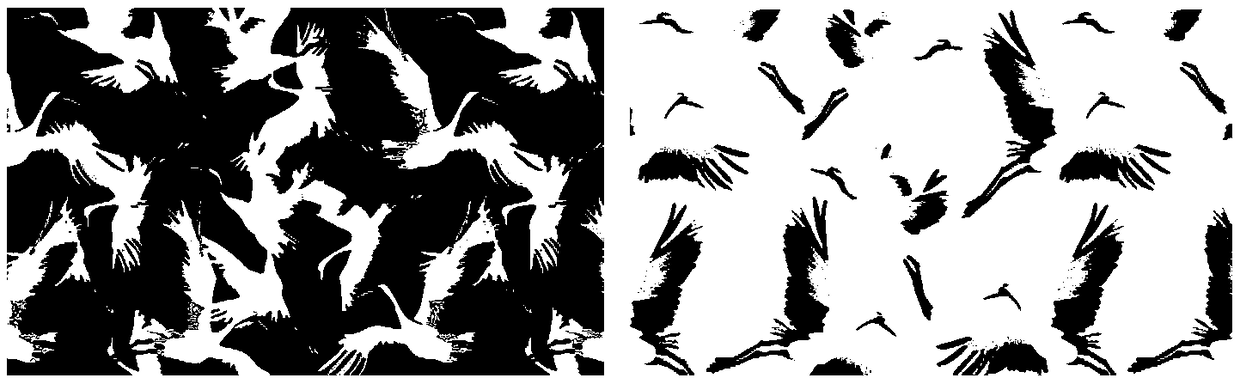

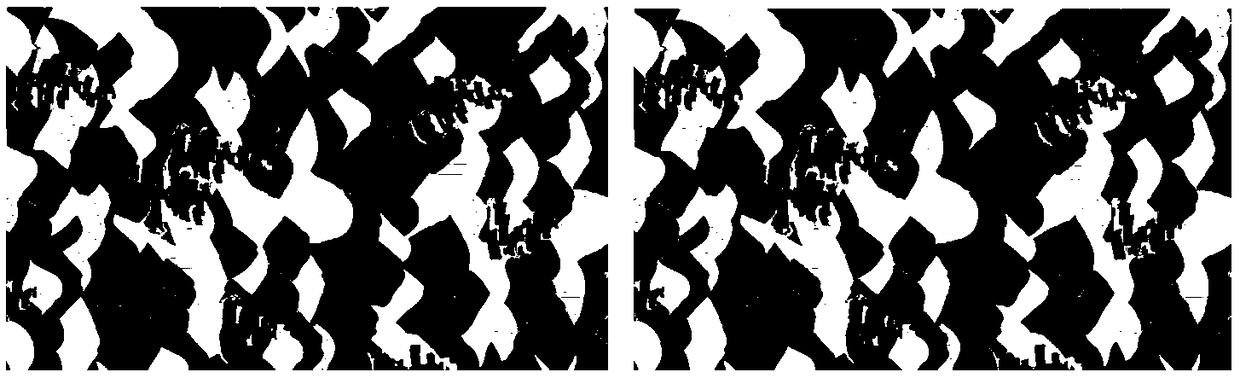

Image

Examples

Embodiment 1

[0042] This embodiment provides a method for double-sided digital printing of cashmere woven fabrics, comprising the following steps:

[0043] S1, whole weft sizing;

[0044] Firstly, weave the colored weft yarn according to the size of the customer to obtain the woven fabric, and then use the card cloth to adjust the outer tenter according to the size of the woven fabric. The woven fabric is subjected to a sizing process before printing on the continuous padding equipment, specifically, the sizing liquid is applied to the woven fabric with a sizing liquid rate of 60-120%.

[0045] Further, the slurry included 4 parts guar gum, 1 part mild acid and 1 part slow release acid and 94 parts demineralized water.

[0046] After the sizing is completed, the second alignment tentering is carried out, and then drying is carried out.

[0047] S2, hair removal;

[0048] Using a laser to shorten the length of the fluffy cashmere after drying, so that the length of the cashmere is 2 mm. ...

Embodiment 2

[0055] This embodiment provides a method for double-sided digital printing of cashmere woven fabrics, comprising the following steps:

[0056] S1, whole weft sizing;

[0057] Firstly, weave the colored weft yarn according to the size of the customer to obtain the woven fabric, and then use the card cloth to adjust the outer tenter according to the size of the woven fabric. The woven fabric is subjected to a sizing process before printing on the continuous padding equipment, specifically, the sizing liquid is applied to the woven fabric with a sizing liquid rate of 60-100%.

[0058] Further, the slurry included 8 parts guar gum, 3 parts mild acid and 5 parts slow release acid and 84 parts demineralized water.

[0059] After the sizing is completed, the second alignment tentering is carried out, and then drying is carried out.

[0060] S2, hair removal;

[0061] Using a laser to shorten the length of the fluffy cashmere wool after drying, so that the length of the cashmere wo...

Embodiment 3

[0068] This embodiment provides a method for double-sided digital printing of cashmere woven fabrics, comprising the following steps:

[0069] S1, whole weft sizing;

[0070] Firstly, weave the colored weft yarn according to the size of the customer to obtain the woven fabric, and then use the card cloth to adjust the outer tenter according to the size of the woven fabric. The woven fabric is subjected to a sizing process before printing on the continuous padding equipment, specifically, the sizing liquid is applied to the woven fabric with a sizing liquid rate of 70-100%.

[0071] Further, the slurry included 6 parts guar gum, 2 parts mild acid and 4 parts slow release acid and 88 parts demineralized water.

[0072] After the sizing is completed, the second alignment tentering is carried out, and then drying is carried out.

[0073] S2, hair removal;

[0074] Using a laser to shorten the length of the fluffy cashmere after drying, so that the length of the cashmere is 5 mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com