Antistatic fabric and preparation method thereof

An antistatic and fabric technology, applied in the textile field, can solve problems such as unsatisfactory effects, and achieve the effect of eliminating discomfort, increasing adhesion, and not easy to get dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

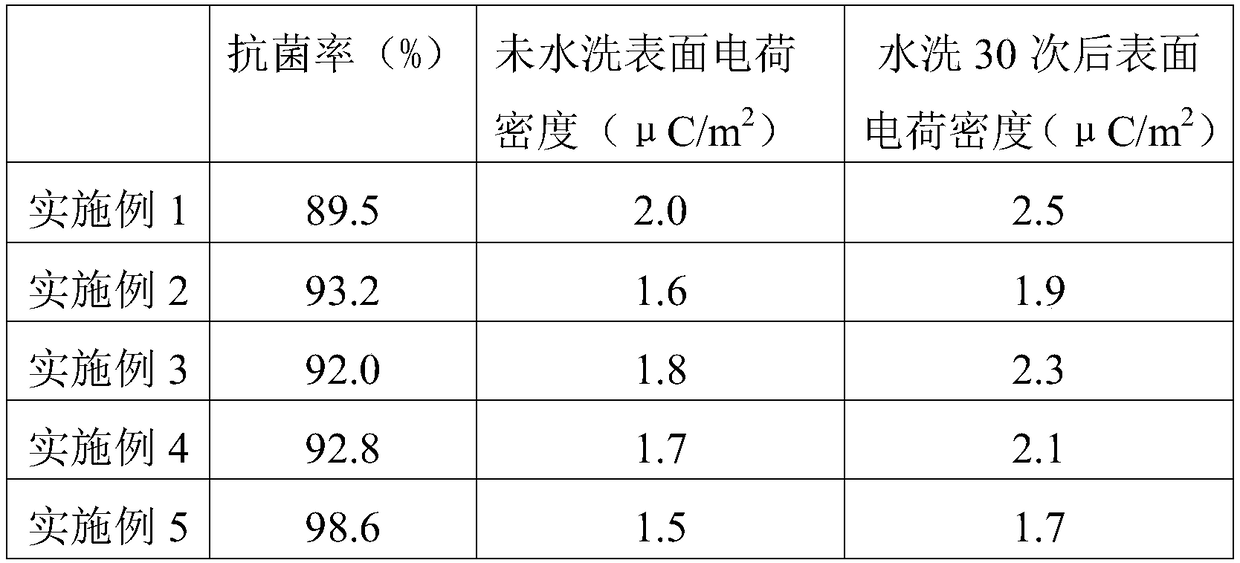

Examples

Embodiment 1

[0029] The antistatic fabric is prepared by the following method:

[0030] Combine 38 parts by weight of Coolmax fiber (Coolmax fiber from INVISTA, 75D) and 59 parts by weight of bamboo fiber ( Fiber, Lyocell bamboo fiber produced by Shanghai Leo Fiber Enterprise Development Co., Ltd.) is blended into blended yarn, then blended yarn and 3 parts by weight of spandex (using DuPont spandex yarn, 70D) are used for knitting and weaving on a large circular knitting weft knitting machine. The plain weave fabric is obtained, and the weight of the plain weave fabric is 200 g / m2; the plain weave fabric is subjected to antistatic finishing, and the antistatic finishing is to immerse the plain weave fabric in an antistatic finishing solution at a temperature of 40°C for 40 minutes. The mass ratio of plain weave fabric to antistatic finishing solution is 1:20. After dehydration, it is dried at 45℃ for 24h to obtain antistatic fabric.

[0031] The antistatic finishing solution is prepared by th...

Embodiment 2

[0034] The antistatic fabric is prepared by the following method:

[0035] 38 parts by weight of Coolmax fiber (Coolmax fiber from INVISTA, 75D) and 59 parts by weight of bamboo fiber ( Fiber, Lyocell bamboo fiber produced by Shanghai Leo Fiber Enterprise Development Co., Ltd.) is blended into blended yarn, then blended yarn and 3 parts by weight of spandex (using DuPont spandex yarn, 70D) are used for knitting and weaving on a large circular knitting weft knitting machine. The plain weave fabric is obtained, and the weight of the plain weave fabric is 200 g / m2; the plain weave fabric is subjected to antistatic finishing, and the antistatic finishing is to immerse the plain weave fabric in an antistatic finishing solution at a temperature of 40°C for 40 minutes. The mass ratio of plain weave fabric to antistatic finishing solution is 1:20. After dehydration, it is dried at 45℃ for 24h to obtain antistatic fabric.

[0036] The antistatic finishing solution is prepared by the follow...

Embodiment 3

[0040] The antistatic fabric is prepared by the following method:

[0041] Combine 38 parts by weight of Coolmax fiber (Coolmax fiber from INVISTA, 75D) and 59 parts by weight of bamboo fiber ( Fiber, Lyocell bamboo fiber produced by Shanghai Leo Fiber Enterprise Development Co., Ltd.) is blended into blended yarn, and then blended yarn and 3 parts by weight of spandex (using DuPont spandex yarn, 70D) are used for knitting and weaving on a large circular knitting weft knitting machine. The plain weave fabric is obtained, and the weight of the plain weave fabric is 200 g / m2; the plain weave fabric is subjected to antistatic finishing, and the antistatic finishing is to immerse the plain weave fabric in an antistatic finishing solution at a temperature of 40°C for 40 minutes. The mass ratio of plain weave fabric to antistatic finishing solution is 1:20. After dehydration, it is dried at 45℃ for 24h to obtain antistatic fabric.

[0042] The antistatic finishing solution is prepared b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com