Dye conveying device used for spandex yarn dyeing

A yarn dyeing and feeding technology, which is applied in the directions of processing textile material carriers, processing textile material containers, and removing liquid/gas/vapor with squeeze rollers, can solve the problems of cumbersome production process, high cost, and uneven yarn dyeing. and other problems, to achieve the effect of saving work steps, improving the effect, and improving the dyeing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

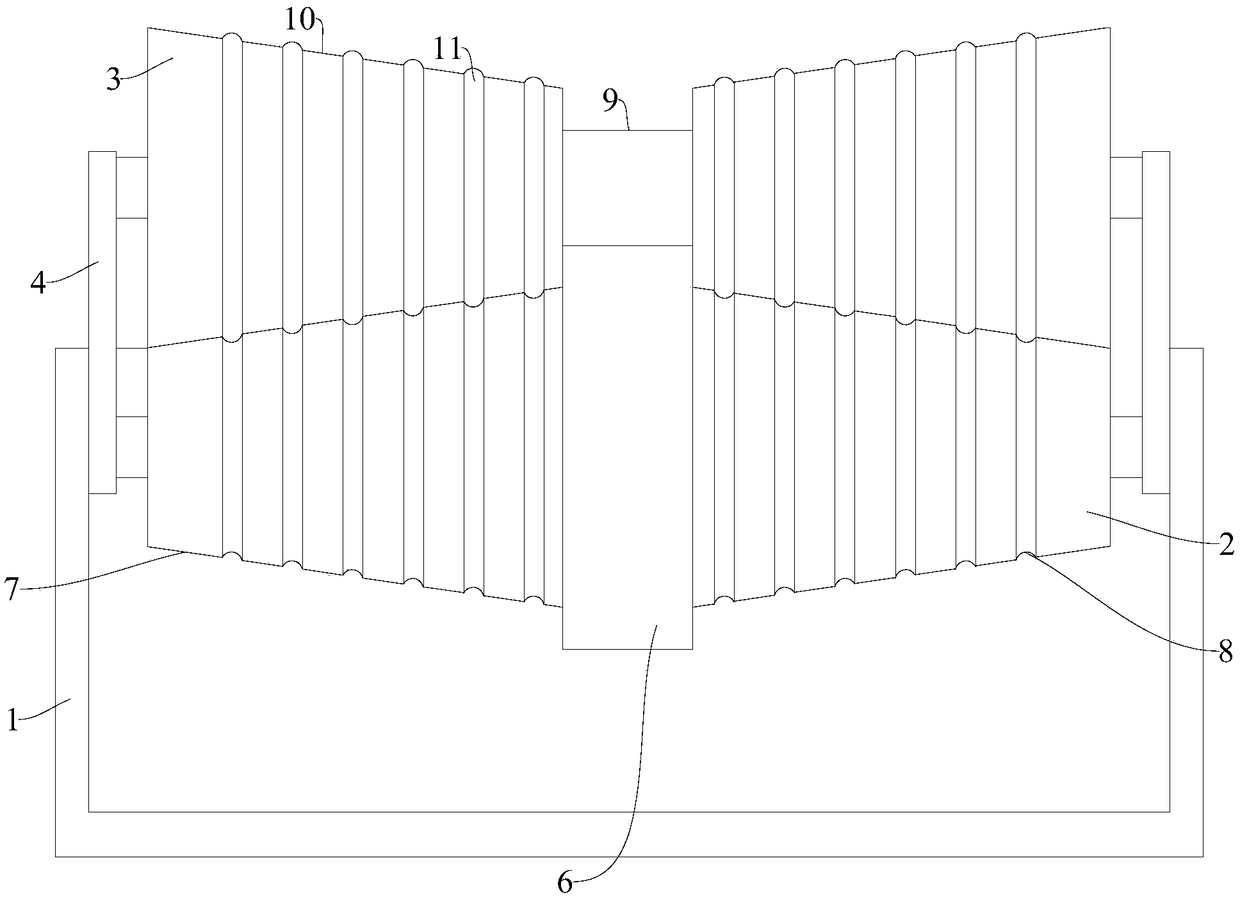

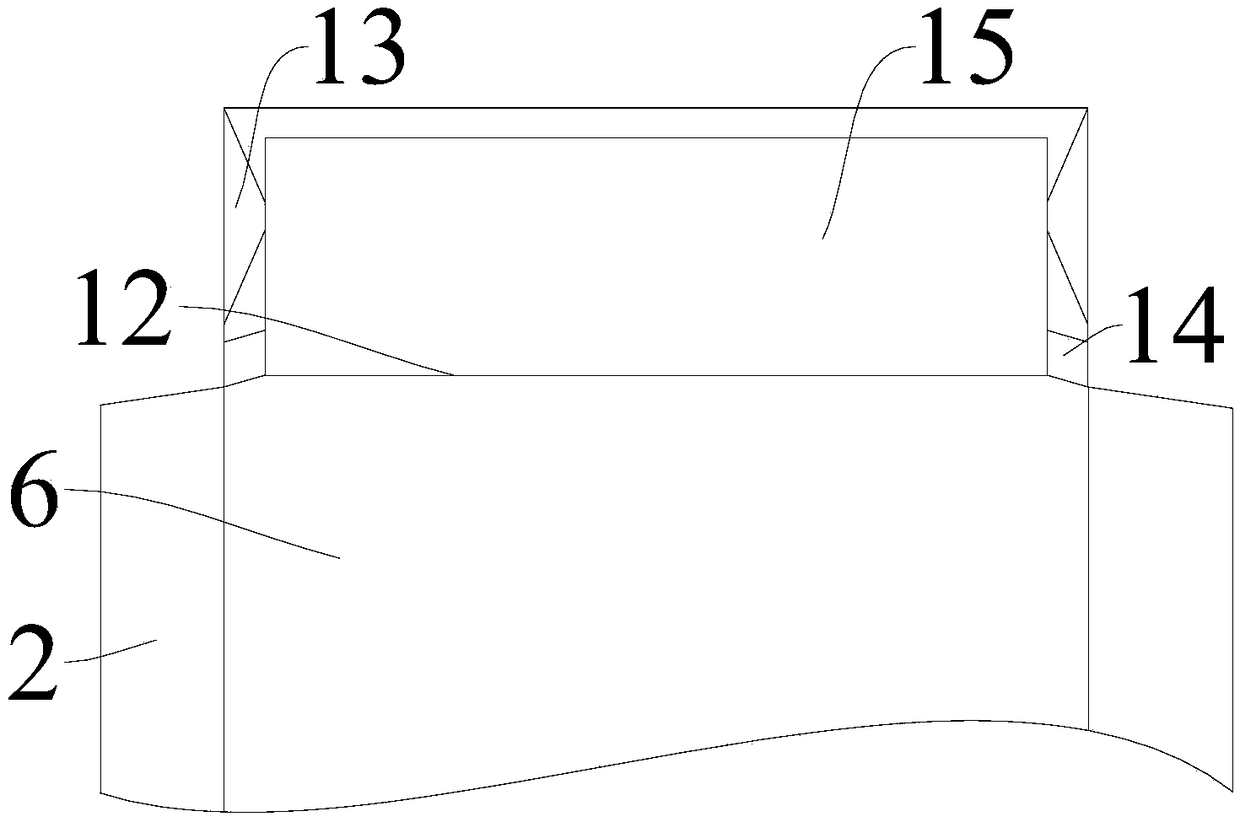

[0015] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0016] figure 1 and figure 2 A conveying device for spandex yarn dyeing as shown, including a dye vat 1 containing dye, a bottom support roller 2 located at the opening inside the dye vat 1 and a top squeeze roller 3 above the bottom support roller 2 , the inner walls on both sides of the dyeing vat 1 are fixedly connected with lateral connection brackets 4 by bolts, and the bottom support roller 2 and the top squeeze roller 3 are inserted into the connection through holes on the corresponding position of the lateral connection bracket 4 through the rotating shafts on both sides and laterally. The connecting bracket 4 is movably connected, the middle sectio...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap