Tuning liquid column damper with multiple real-time adjustment damping

A technology for tuning liquid column damping and real-time adjustment, which is applied in the direction of shock absorbers, shock absorbers, springs/shock absorbers, etc., and can solve the problems of inability to adjust in real time, rapid adjustment of vibration intensity, and inability to realize super-high buildings and structures The most effective control of vibration and other issues to achieve the effect of ensuring safety and applicability, low energy consumption, and high damping adjustment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

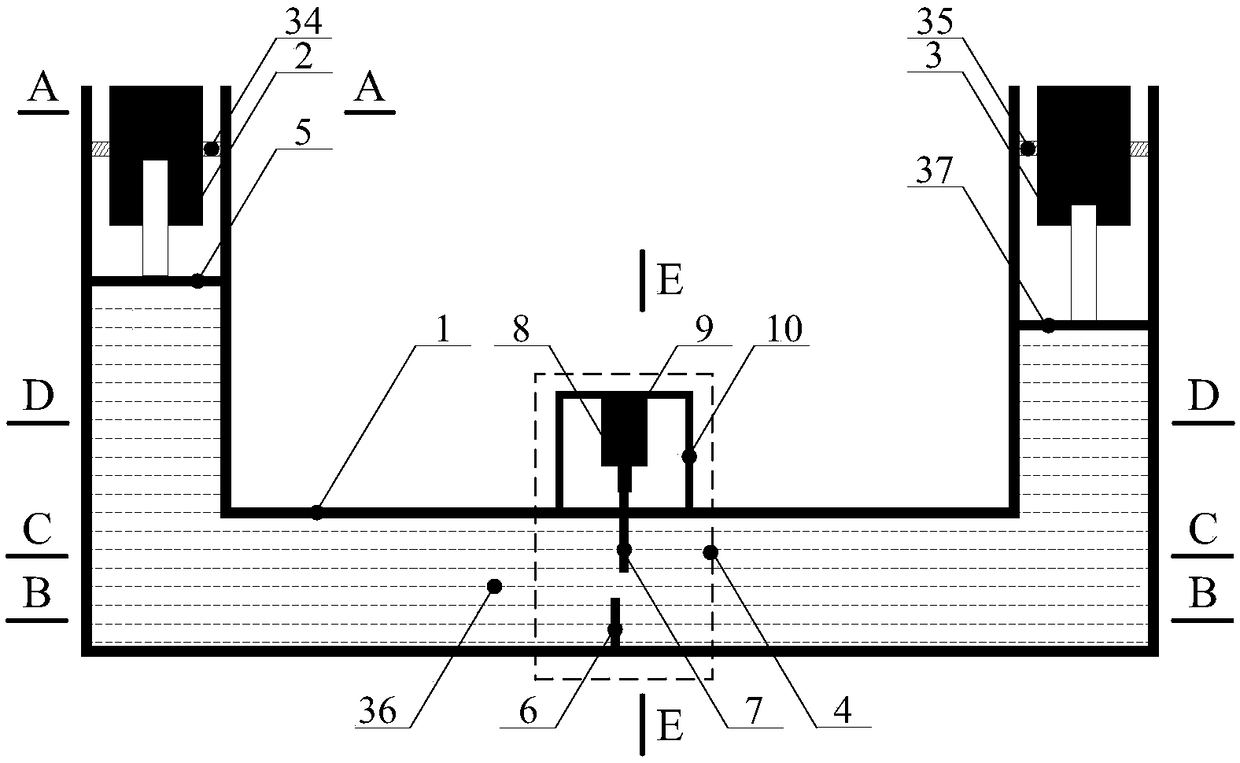

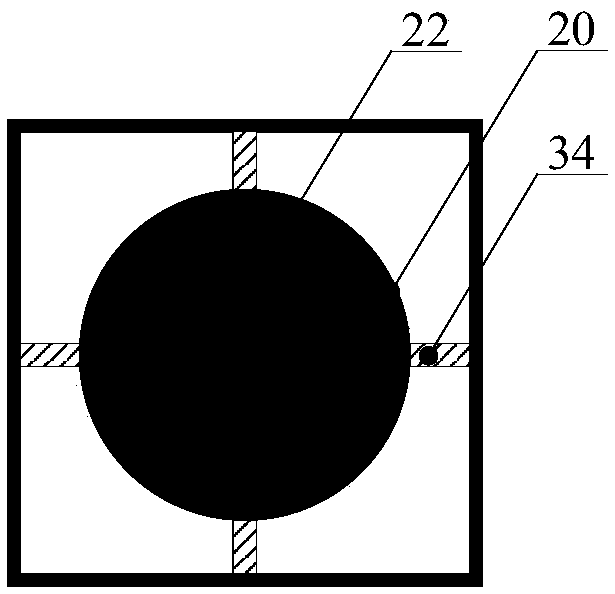

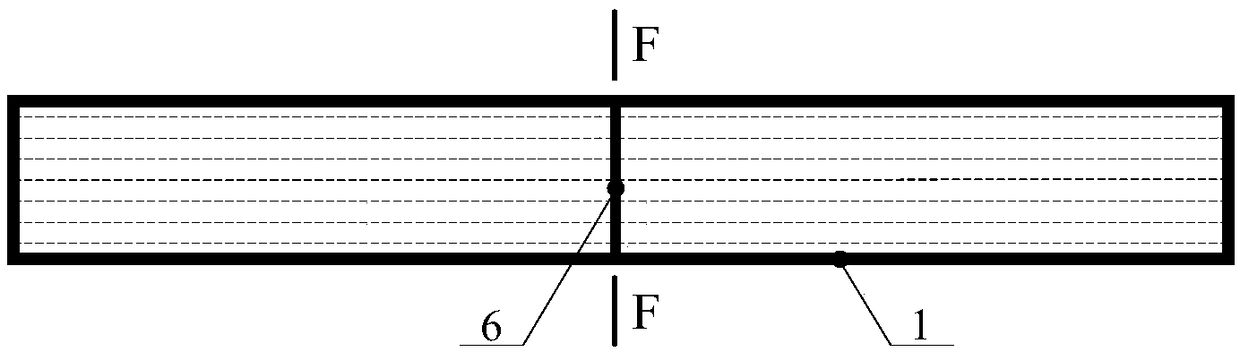

[0027] Such as Figure 1-8As shown, a tuned liquid column damper with multiple real-time damping adjustments includes: a U-shaped tubular water tank 1, a first magnetorheological damper 2, a second magnetorheological damper 3 and a water hole adjustment mechanism 4, the first The magnetorheological damper 2 is slidingly connected to the water tank 1 through the first water retaining plate 5, and the second magnetorheological damper 3 is slidingly connected to the water tank 1 through the second water retaining plate 37. The water tank 1 is filled with liquid 36, and the first The water retaining plate 5 and the second water retaining plate 37 are all located at the liquid level position of the vertical section of the U-shaped tubular water tank 1 with equal cross-section, and the shell 20 of the first magneto-rheological damper 2 is fixed on the water tank 1 through the first bracket 34, The housing 20 of the second magneto-rheological damper 3 is fixed on the water tank 1 thr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com