Automatic inflation releasing device of shipborne sounding balloon

An air-exploration balloon and automatic inflation technology, which is applied in the container filling method, the container discharge method, the fixed-capacity air storage tank, etc., can solve the problems of complicated operation steps, inability to hold the balloon, and increase the pressure of personnel, so as to reduce the number of personnel. Use, improve work efficiency and practicability, and improve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

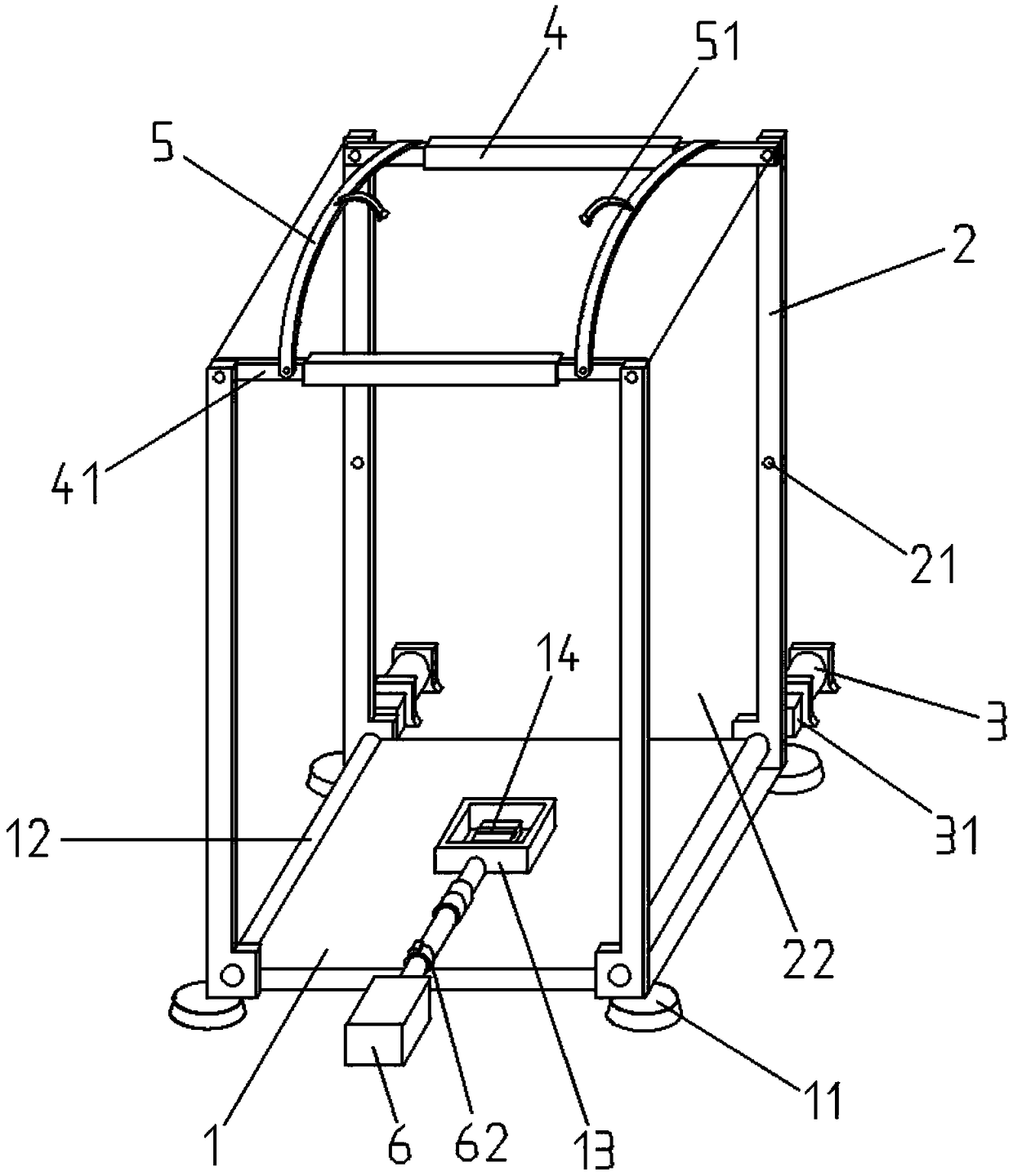

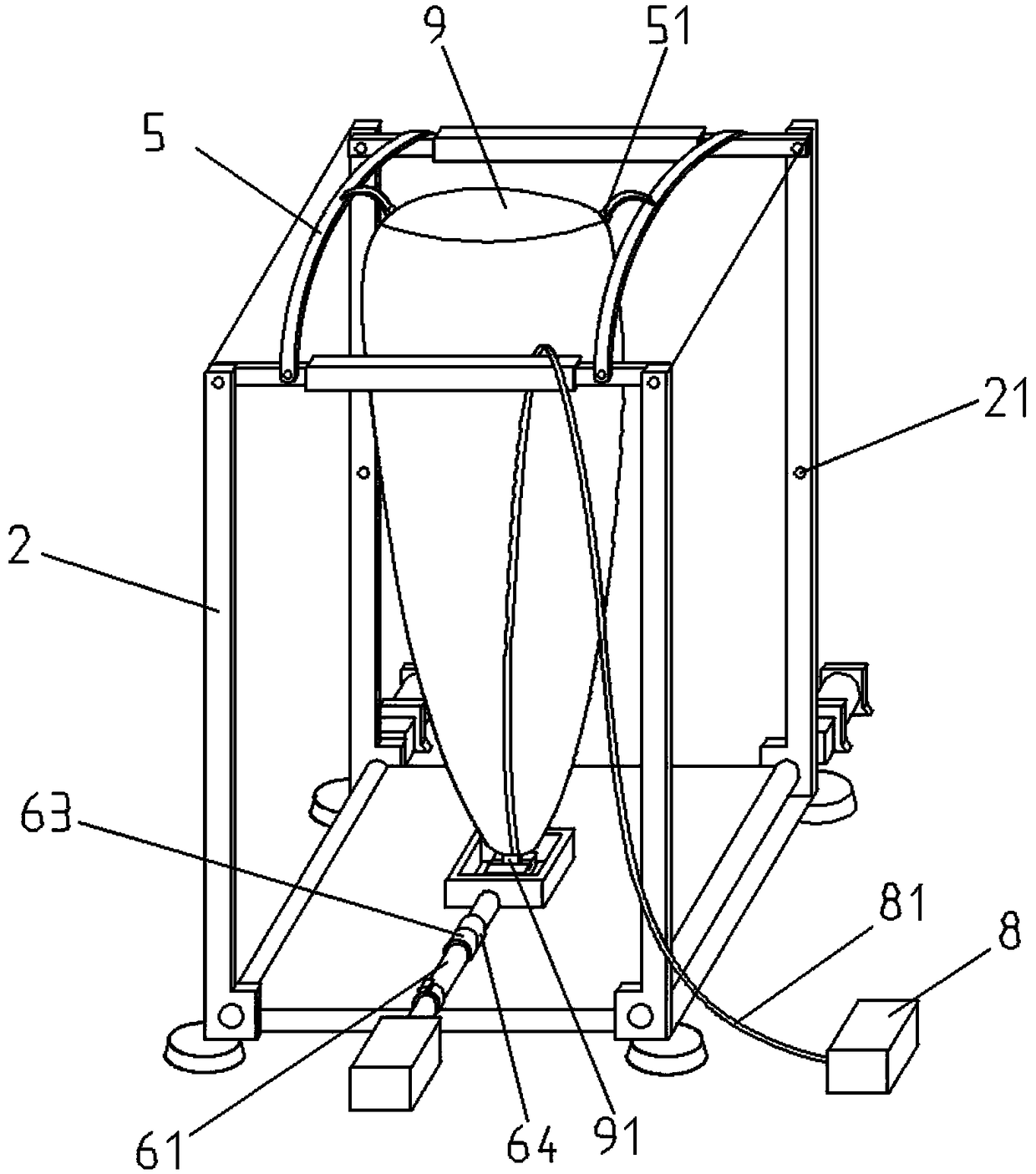

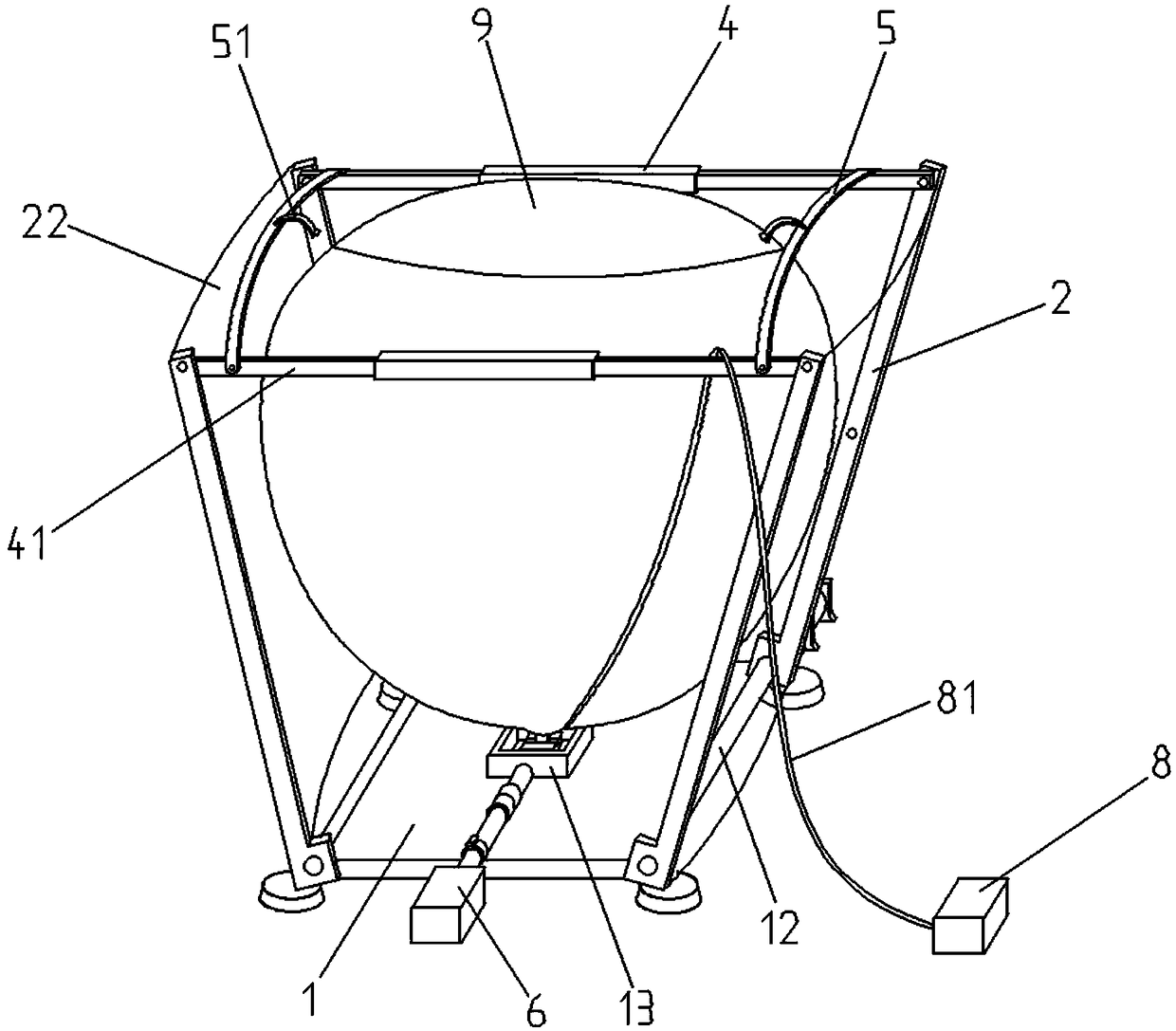

[0027] Such as Figure 1 to Figure 4 As shown, a ship-borne sounding balloon automatic inflation release device and its use method include a base frame 1, a fixed support 11, a rotating shaft 12, a mounting base 13, an electric lock 14, a rotating side frame 2, and an infrared sensing module 21 , elastic membrane 22, rotary motor 3, secondary reducer 31, telescopic rod body 4, extension rod 41, elastic limit belt 5, positioning clip 51, inflation source 6, transmission pipeline 61, pressure detection module 62, solenoid valve 63 , a flow controller 64, a control module 7, a data processing module 71, a fixed block 8, a rope 81, a balloon 9, an inflatable one-way valve 91, and the underframe 1 is installed through a plurality of fixed supports 11 provided at the bottom On the hull, a rotating shaft 12 is respectively arranged inside the two sides of the bottom frame 1, and a rotating side frame 2 is respectively arranged at both ends of the rotating shaft 12, and an elastic fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com