A preparation device and method for spectral sample control

A preparation device and spectrum technology, which is applied in the field of spectrum control sample preparation, can solve the problems of bottom shrinkage, porosity, and top shrinkage, and achieve the effects of improving composition uniformity, improving fluidity, and increasing top feeding capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention provides many applicable inventive concepts that can be embodied in numerous specific contexts. The specific examples described in the following embodiments of the present invention are only used as illustrations of specific embodiments of the present invention, and are not intended to limit the scope of the present invention.

[0047] First the nouns involved in the present invention are explained:

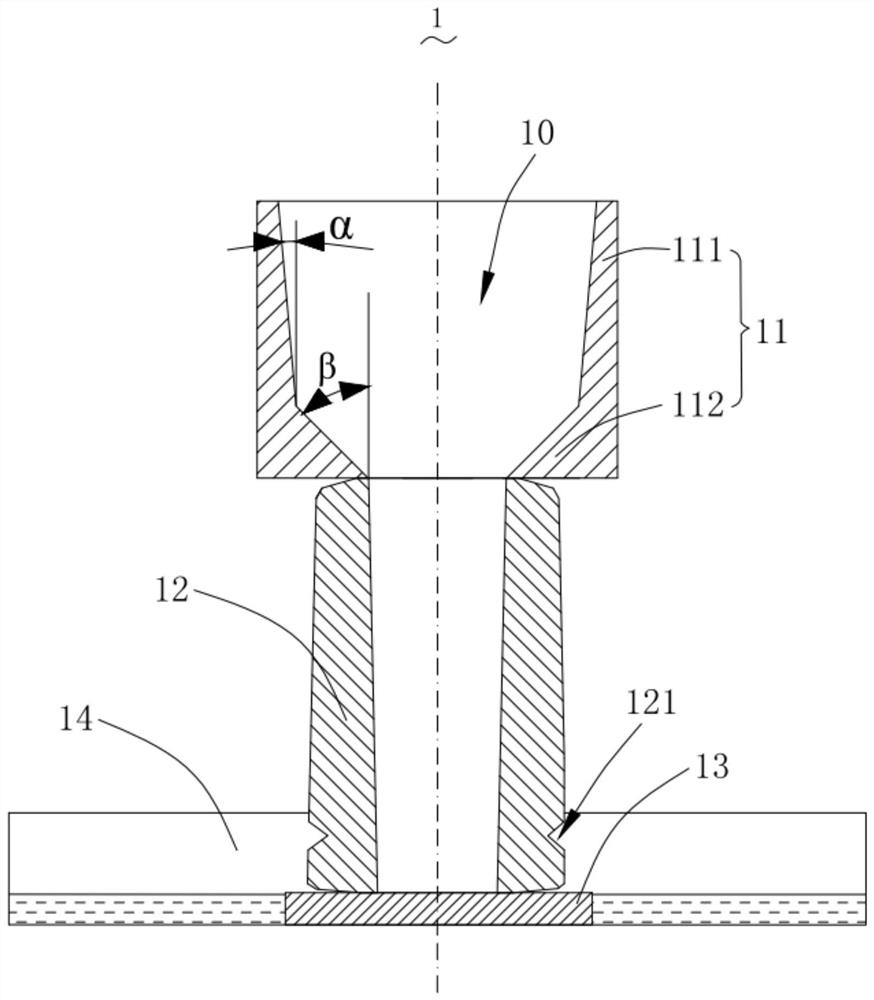

[0048] Taper C: refers to the ratio of the diameter D of the bottom circle of the cone to the height H. Usually, the taper can be written in the form of 1:n. If it is a truncated cone, it is the ratio of the difference between the diameters of the upper and lower bottom circles to the height of the truncated cone.

[0049] Cone angle α: refers to the angle between the two generatrices of the axial section of the cone (the section passing through the axis of the cone). Taper C and taper angle α can be converted to each other, the relationship is: C=2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com