Microphone

A microphone and cantilever technology, applied in sensor parts, magnetic field-controlled resistors, sensors, etc., can solve the problems of overall performance changes, limit the high signal-to-noise ratio performance of microphones, and yield loss, and achieve the effect of improving the signal-to-noise ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical problems solved by the present invention, the technical solutions adopted, and the technical effects obtained easy to understand, the specific implementation manners of the present invention will be further described below in conjunction with the specific drawings.

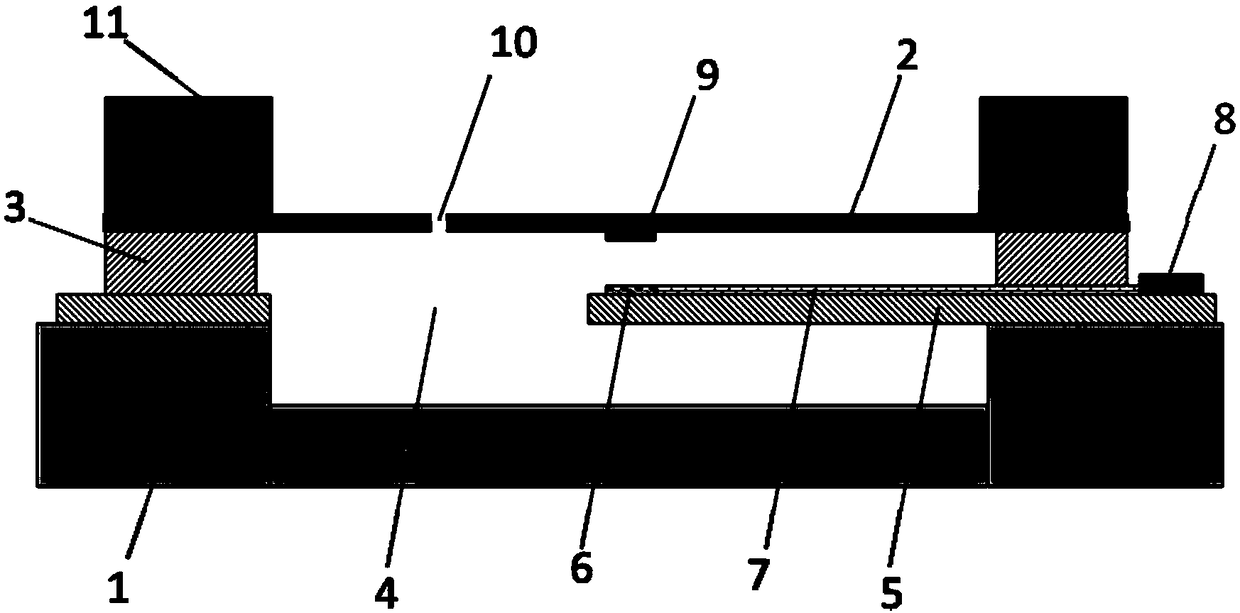

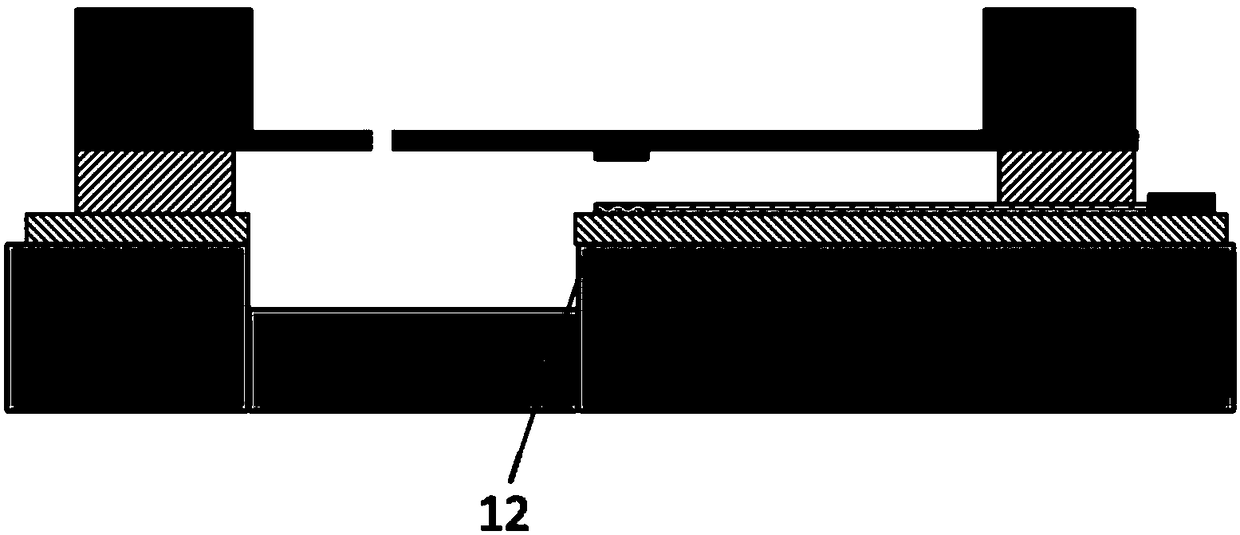

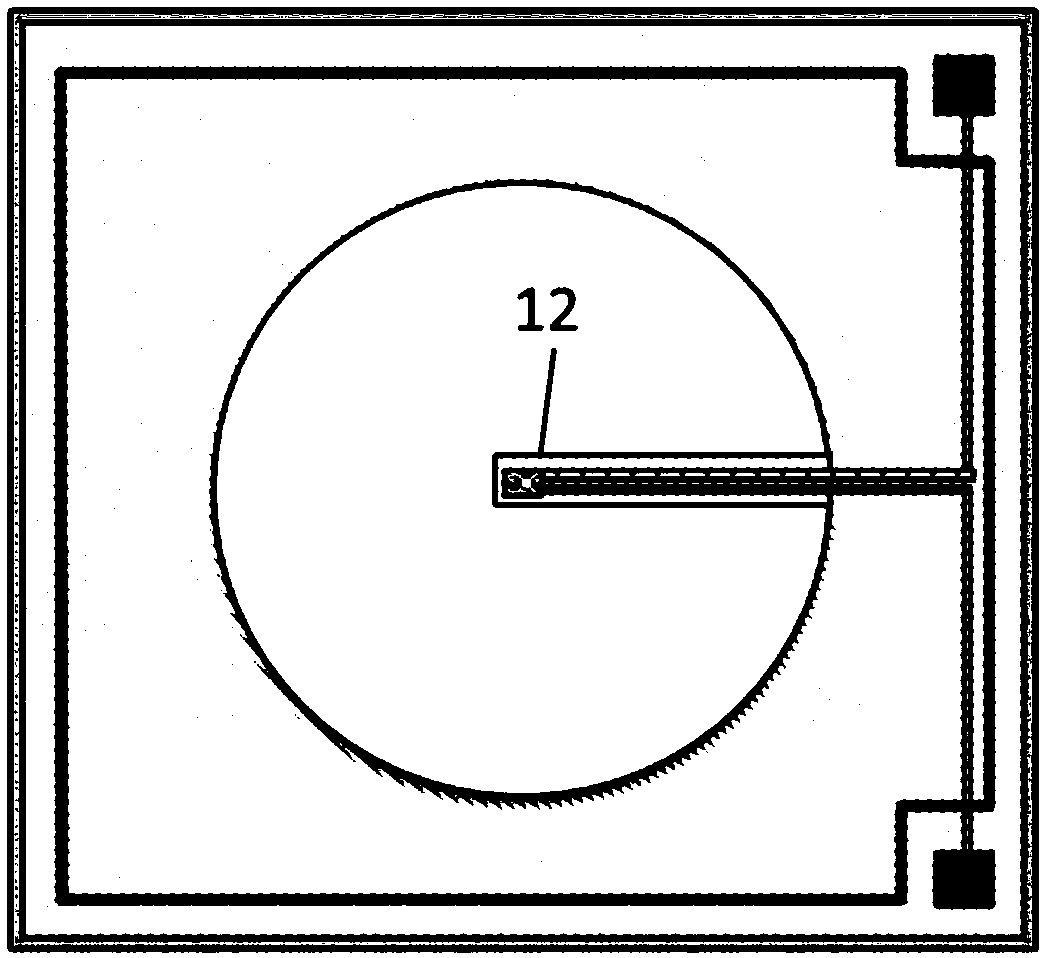

[0026] refer to figure 1 , the present invention provides a microphone, which includes a first substrate 1 , a diaphragm 2 and at least one cantilever 5 located on the first substrate 1 .

[0027] The first substrate 1 has an inner cavity with an open end, and the edge of the diaphragm 2 and the end of the cantilever 5 are directly or indirectly connected to the first substrate 1, so that the main part of the diaphragm 2 and the cantilever 5 is suspended on the first substrate 1. above the substrate 1 cavity.

[0028] The cantilever 5 and the diaphragm 2 are separated by a spacer 3 , and the height of the spacer 3 is the initial gap between the diaphragm 2 and the cantilever ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com