Curved surface positioning minimally invasive acetabular anterior column screw aimer and preparation method thereof

An acetabular anterior column and positioning technology, applied in the field of medical devices, can solve problems such as high requirements for planners, cumbersome operations, and slippage of drilling molds, so as to ensure accuracy and safety, simplify the positioning process, and ensure screw placement The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

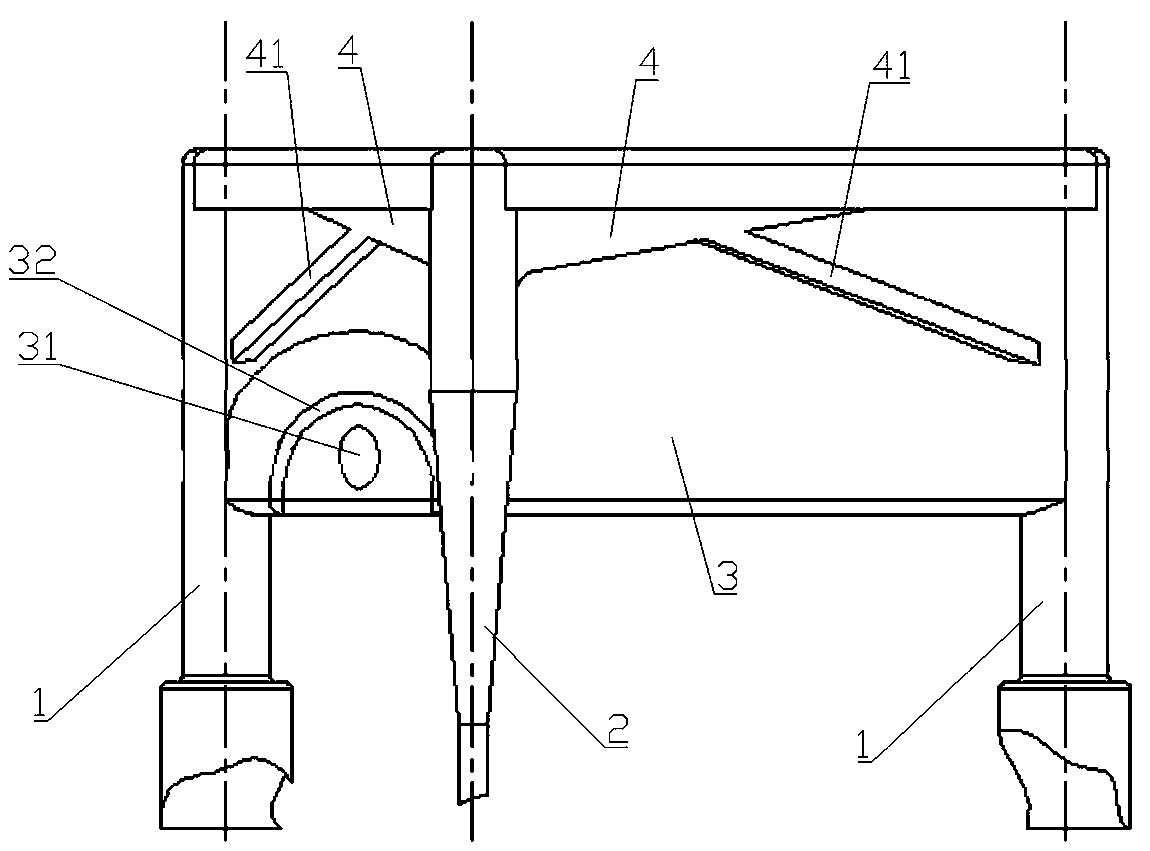

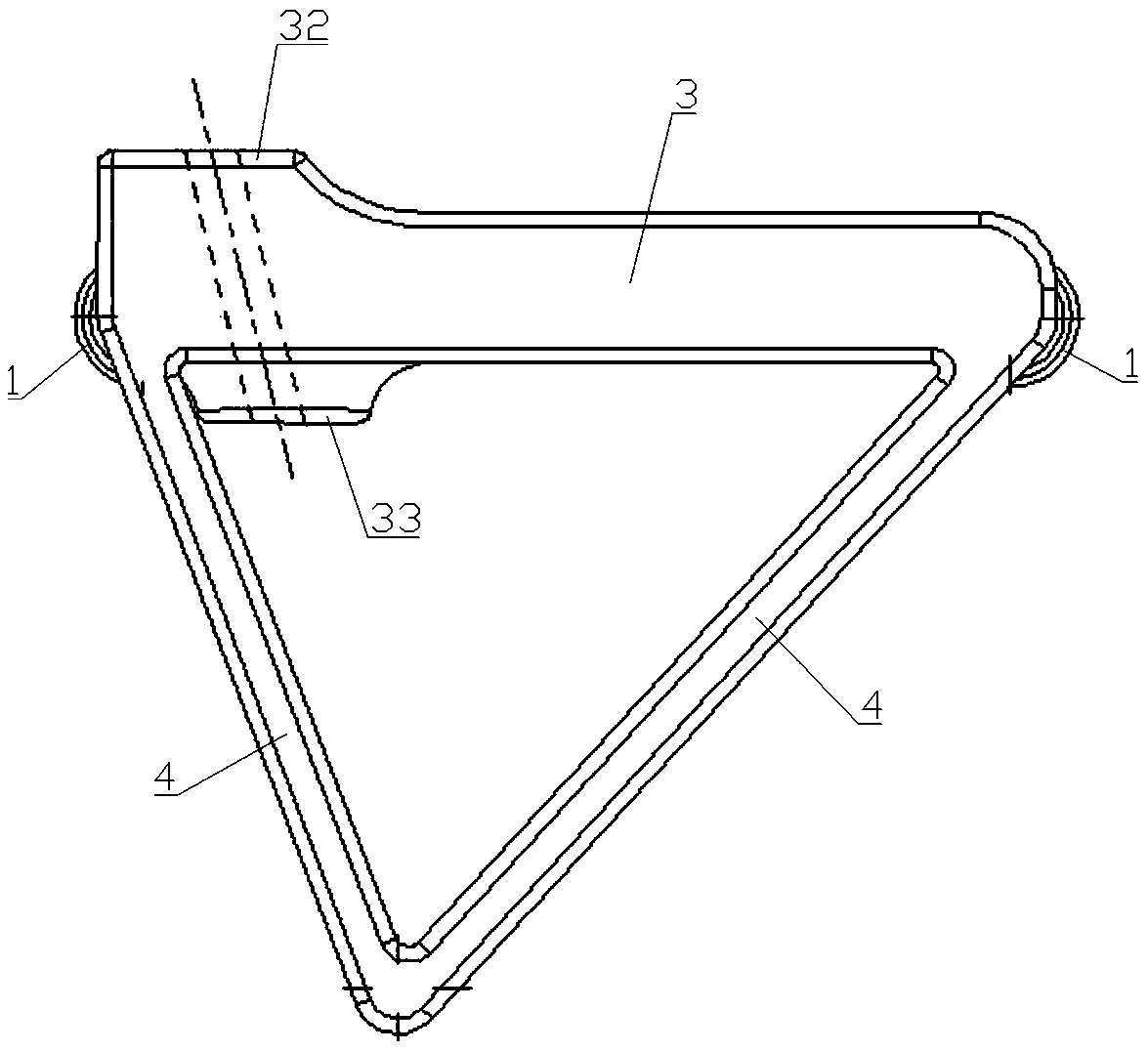

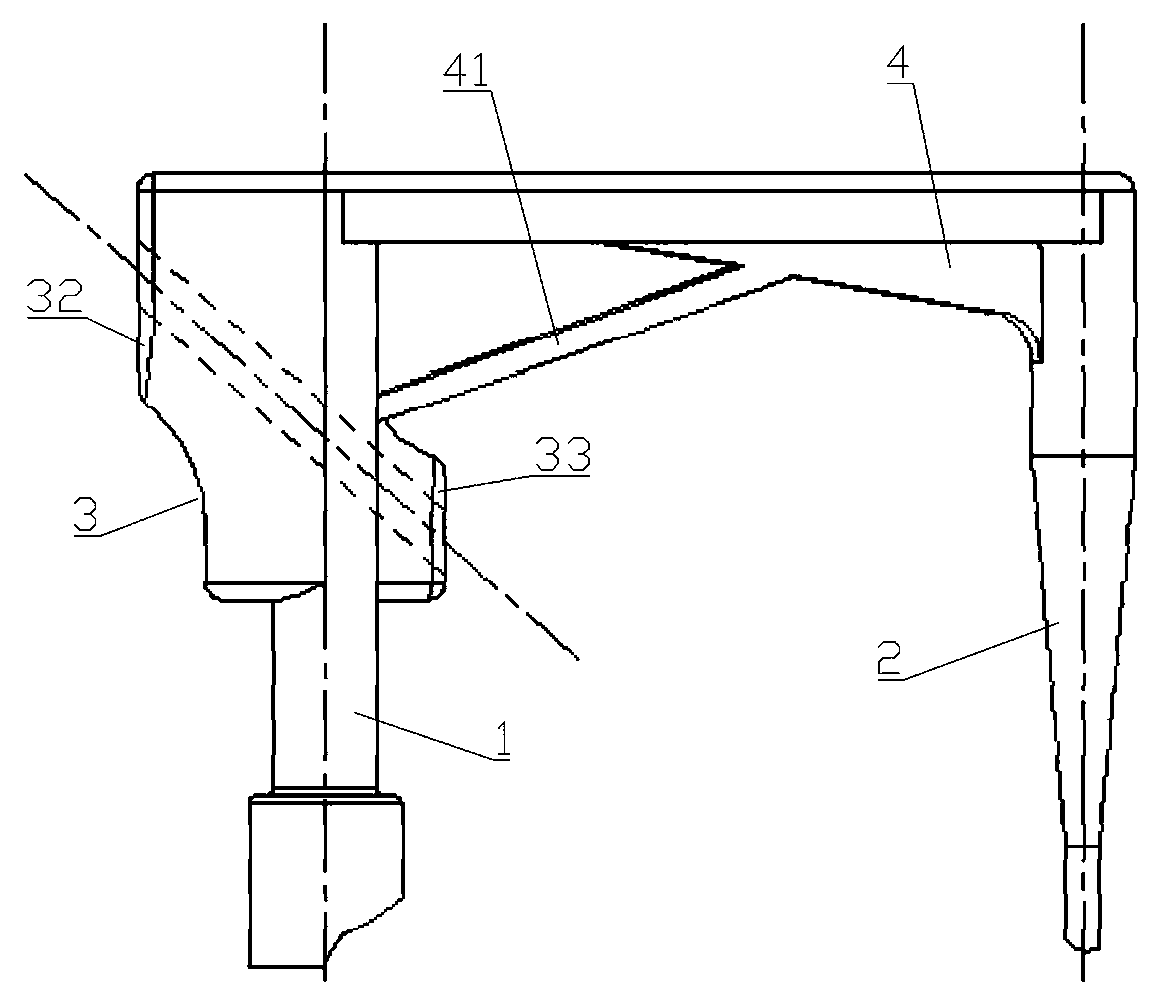

[0058] Such as Figure 1-5 As shown, the curved surface positioning type minimally invasive acetabular anterior column screw aimer includes a body with a triangular truss structure, and the body includes two main positioning feet 1, one auxiliary positioning foot 2, one main support wall 3 and two auxiliary support walls 4.

[0059] The two main positioning feet 1 are parallel and vertically arranged and connected as a whole through the main supporting wall 3. The auxiliary positioning feet 2 are parallel and vertically arranged with the main positioning feet 1 and are respectively supported by an auxiliary support between the two main positioning feet 1. Wall 4 is connected as one.

[0060] The main support wall 3 is rectangular, and there is a guiding mold channel 31 running through its inner and outer surfaces. The lower ends of the two main positioning feet 1 are provided with bone fitting surfaces for positioning, and the bone fitting surfaces at the lower ends of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com