Reactor for water-based titanium alloy cutting fluid

A titanium alloy and cutting fluid technology, applied in the field of water-based titanium alloy cutting fluid reactors, can solve the problems of uneven stirring, demulsification, affecting the quality of water-based titanium alloy cutting fluid products, etc., so as to avoid micro-bubbles and reduce adhesion. Abrasion, not easy to break demulsification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

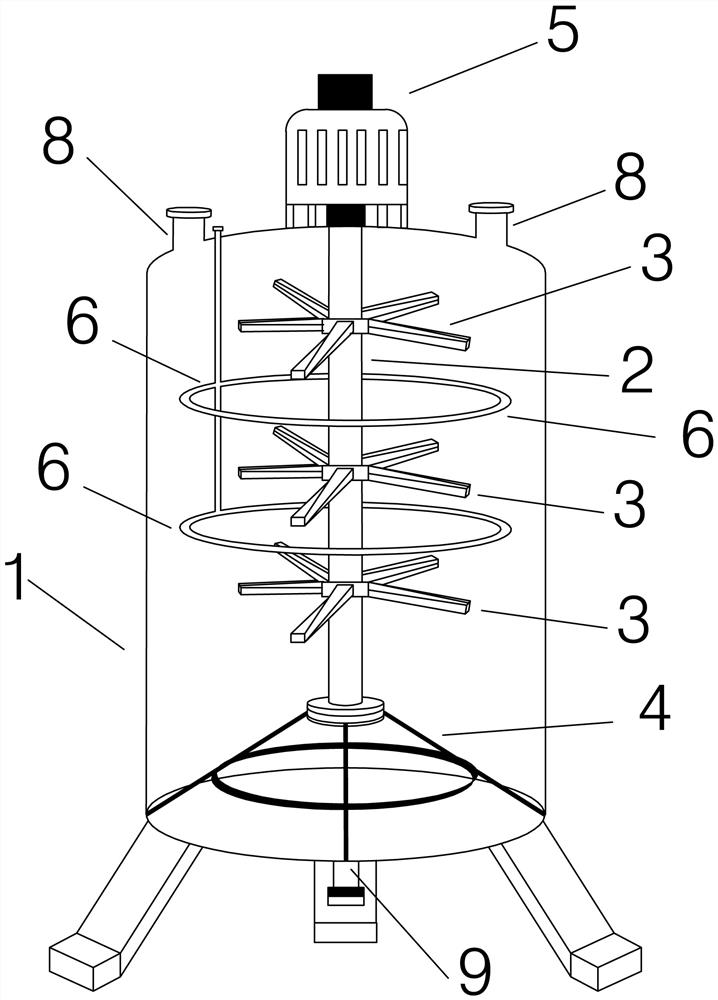

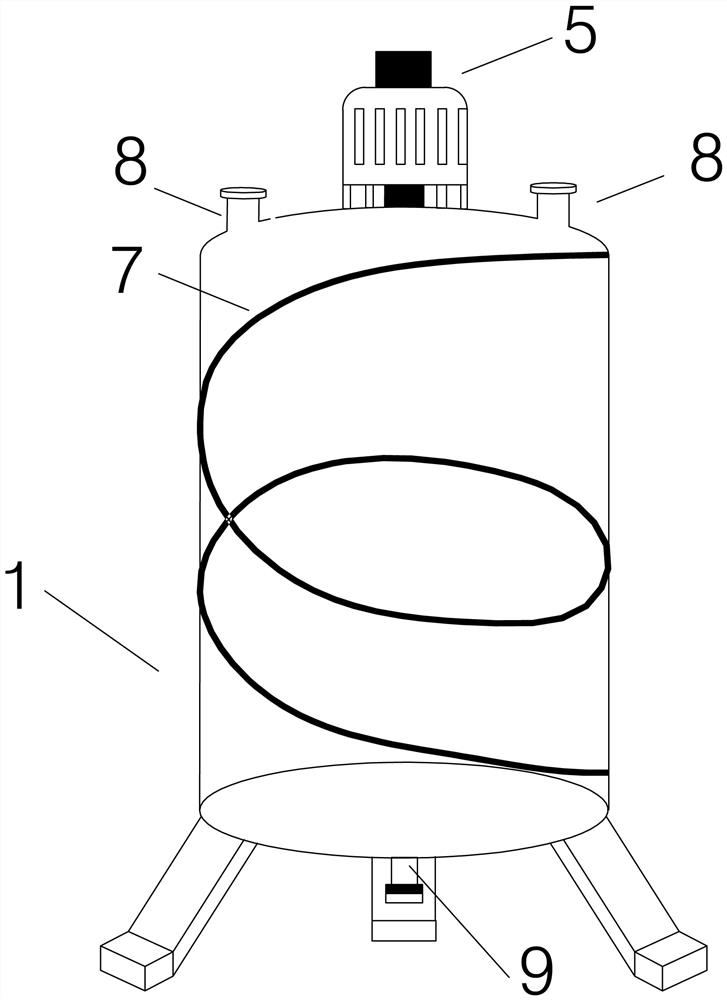

[0024] Such as figure 1 As shown, the reaction kettle of the water-based titanium alloy cutting fluid of the present invention includes a kettle body 1, wherein the kettle body 1 includes a stirring shaft 2 driven by a motor 5 arranged on the top and goes deep into the inner cavity of the kettle body, and the stirring shaft 2 is set There is a stirring paddle 3, and the other end of the stirring shaft 2 is fixed in the support frame 4 at the bottom; the outer side of the stirring shaft 2 is provided with a heating pipe 6; the top of the kettle body 1 is also provided with a feed port 8, and the bottom is provided with a discharge port 9 ; The reactor is used for stirring and mixing water-based titanium alloy cutting fluid containing polyethylene glycol ester lubricant. Further, such as figure 2 As shown, a spiral spoiler 7 is arranged in the inner cavity of the kettle body 1 close to the inner wall.

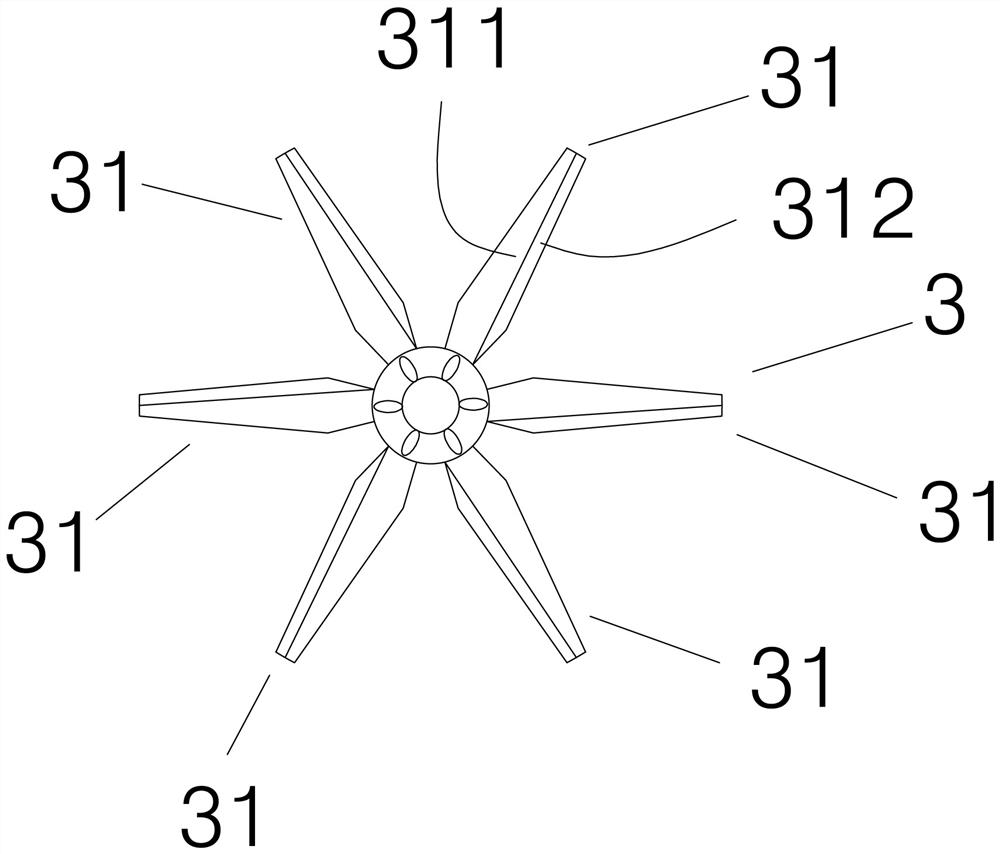

[0025] The structural representation of further stirring paddle 3 is as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com