Paint dipping device for bolt type small workpieces

A small workpiece and paint dipping technology, which is applied to the device and coating of the surface coating liquid, can solve the problems affecting the quality of dipping paint, foreign matter is not easy to remove, and the viscosity of paint liquid is uneven, so as to achieve uniform stirring and ensure Improvement of paint quality and viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

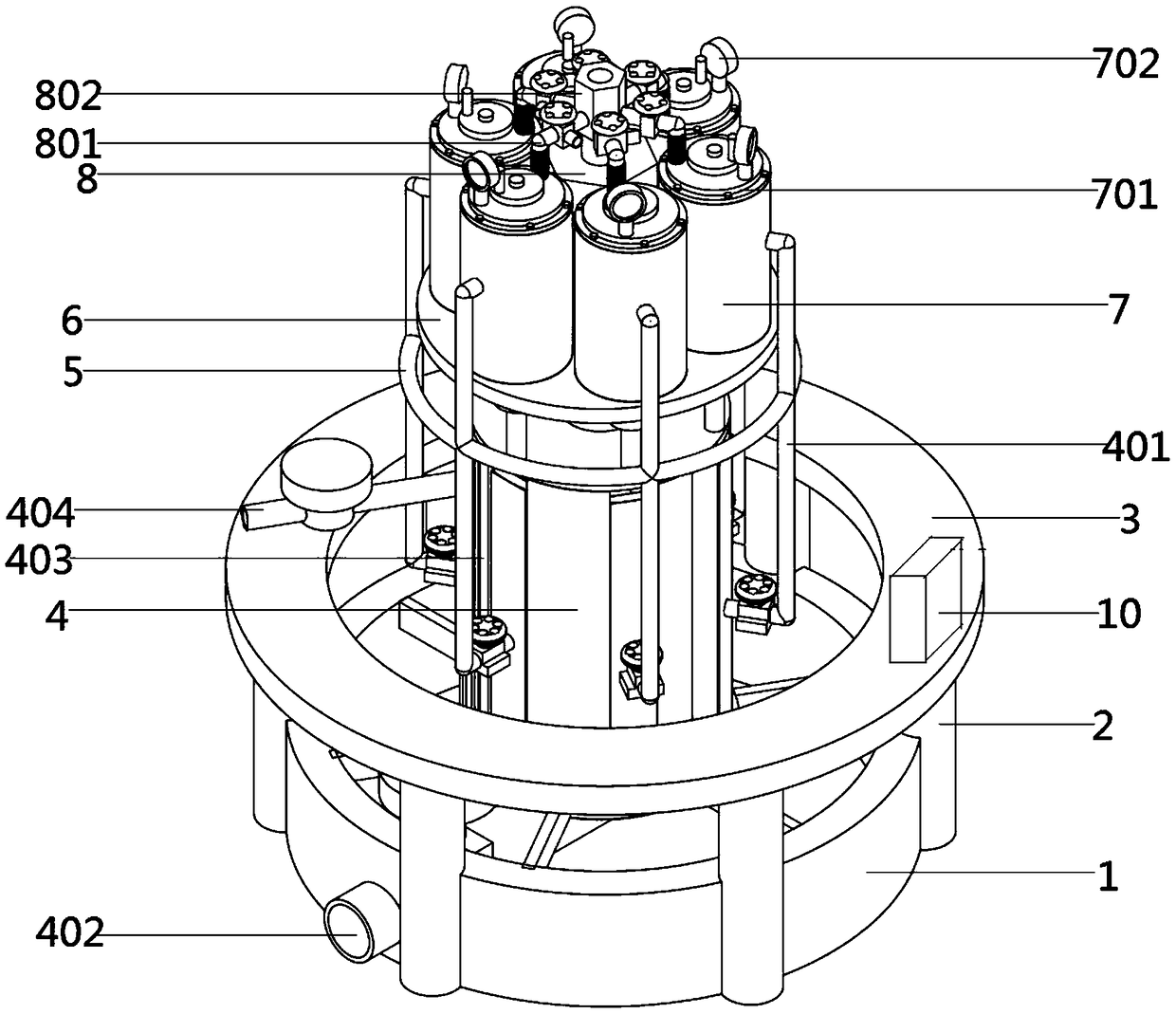

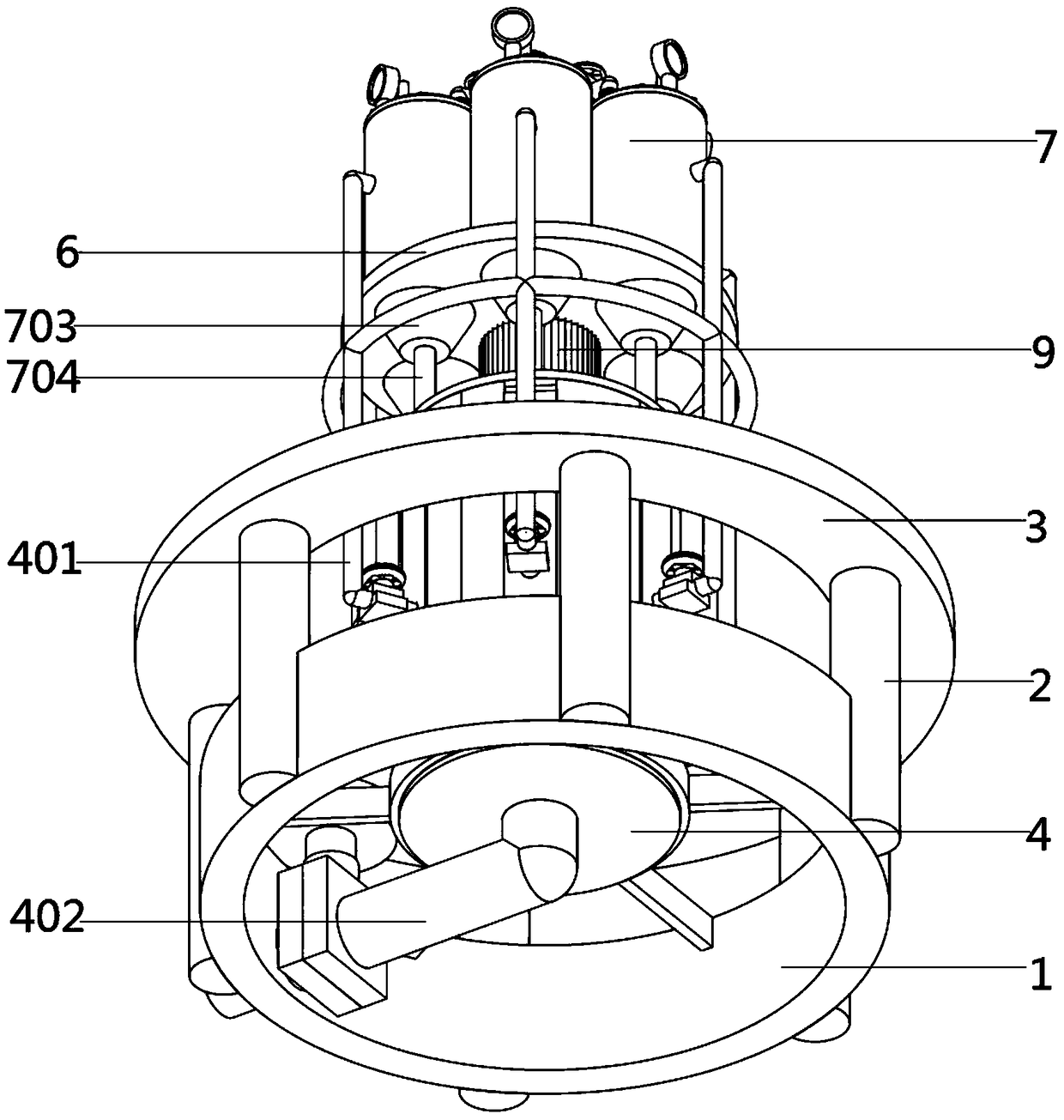

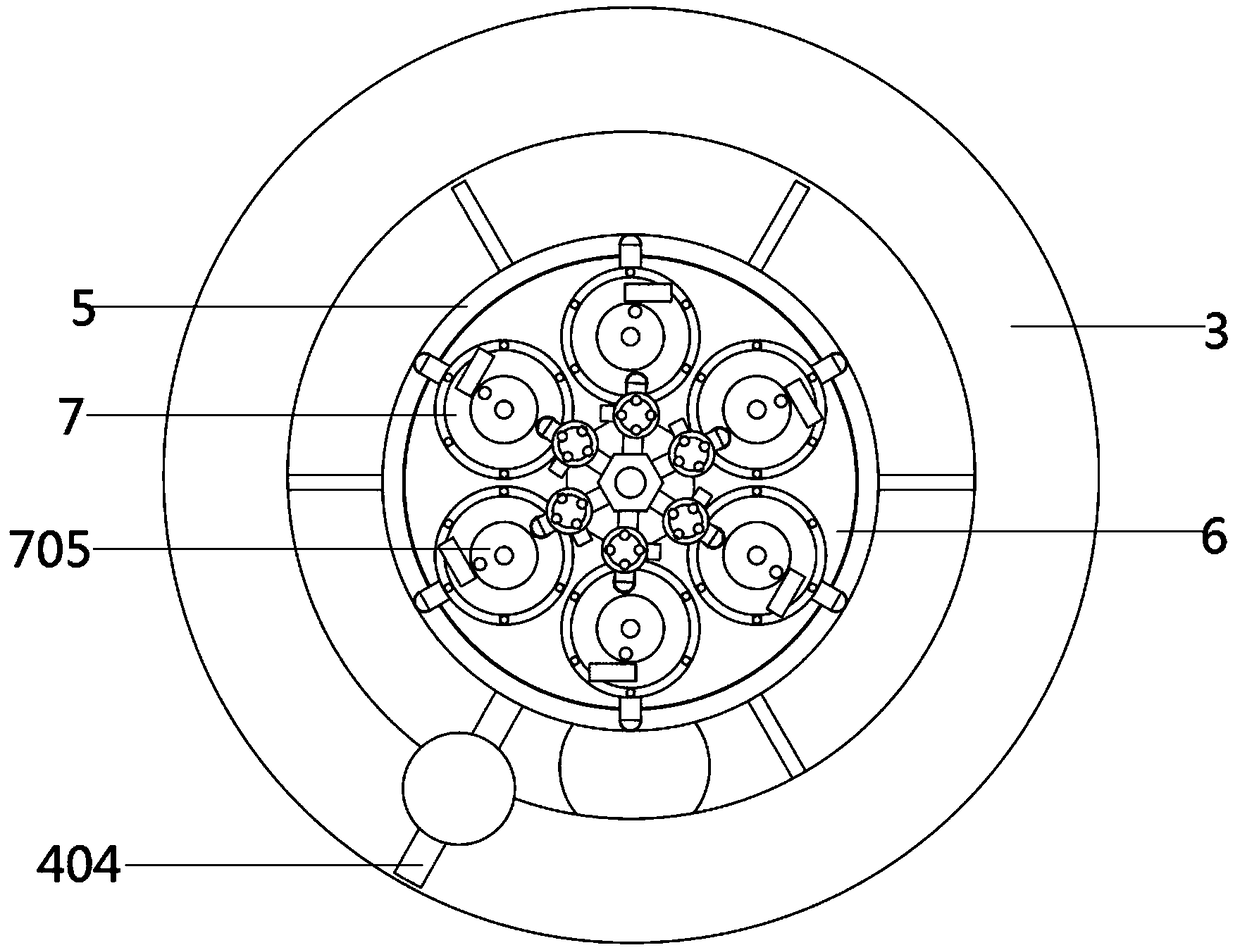

[0035] as attached figure 1 to attach Figure 10 Shown:

[0036]The present invention provides a paint dipping device for small workpieces such as bolts, which includes a base 1, a support column 2, a ring platform 3, a paint storage bucket 4, a shaping ring 5, an upper support plate 6, a paint bucket 7, a vacuum pump 8, and a servo motor 9. Control panel 10, paint inlet pipe 401, paint changing pipe 402, liquid level gauge 403, paint repair pipe 404, paint dip bucket cover 701, pressure gauge 702, tapered paint outlet head 703, paint return pipe 704, paint stirring plate 705 , the lower paint stirring paddle 706, the exhaust pipe 801, the partial pressure conversion head 802, the upper stirring plate 901, the lower stirring plate 902, the outer shaping connecting column 903, the inner stirring column 904, the outer paint scraping paddle 905 and the paint penetration hole 906; The top of the base 1 is vertically provided with six evenly spaced support columns 2 along the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com