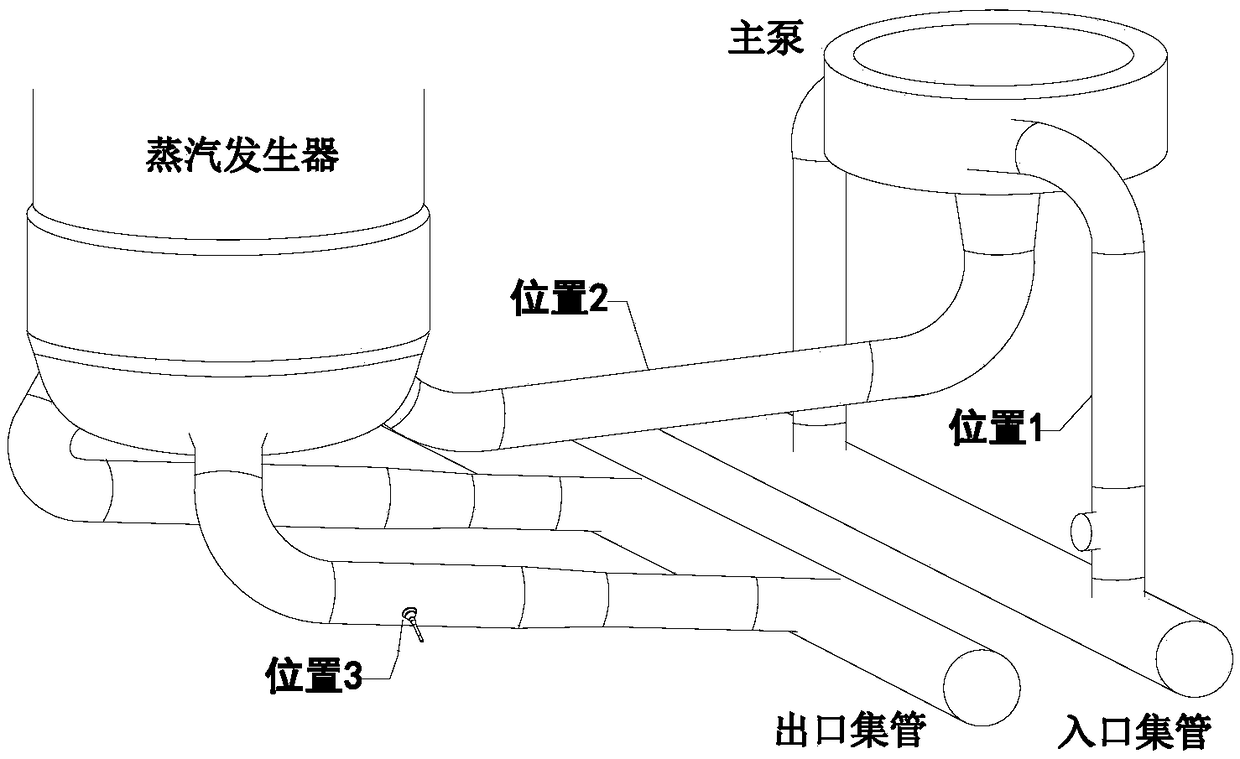

Heavy water reactor main pipeline branch pipe connector surfacing repairing structure

A technology for main pipelines and heavy water reactors, applied to welding equipment, arc welding equipment, and the edge of workpieces, etc., can solve the problems of heavy water reactors losing coolant, core melting, and affecting the safe and stable operation of units, and prevent further expansion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

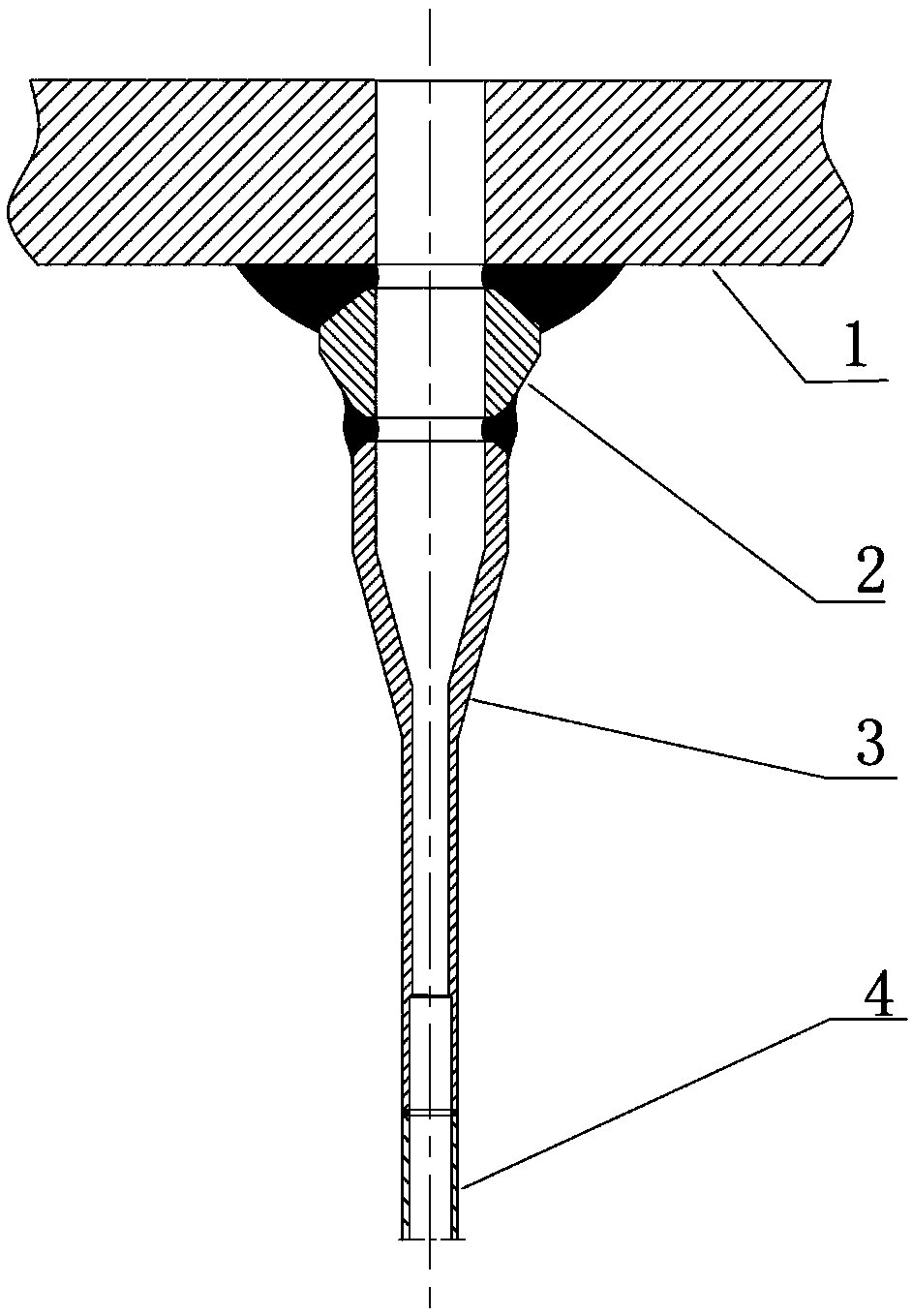

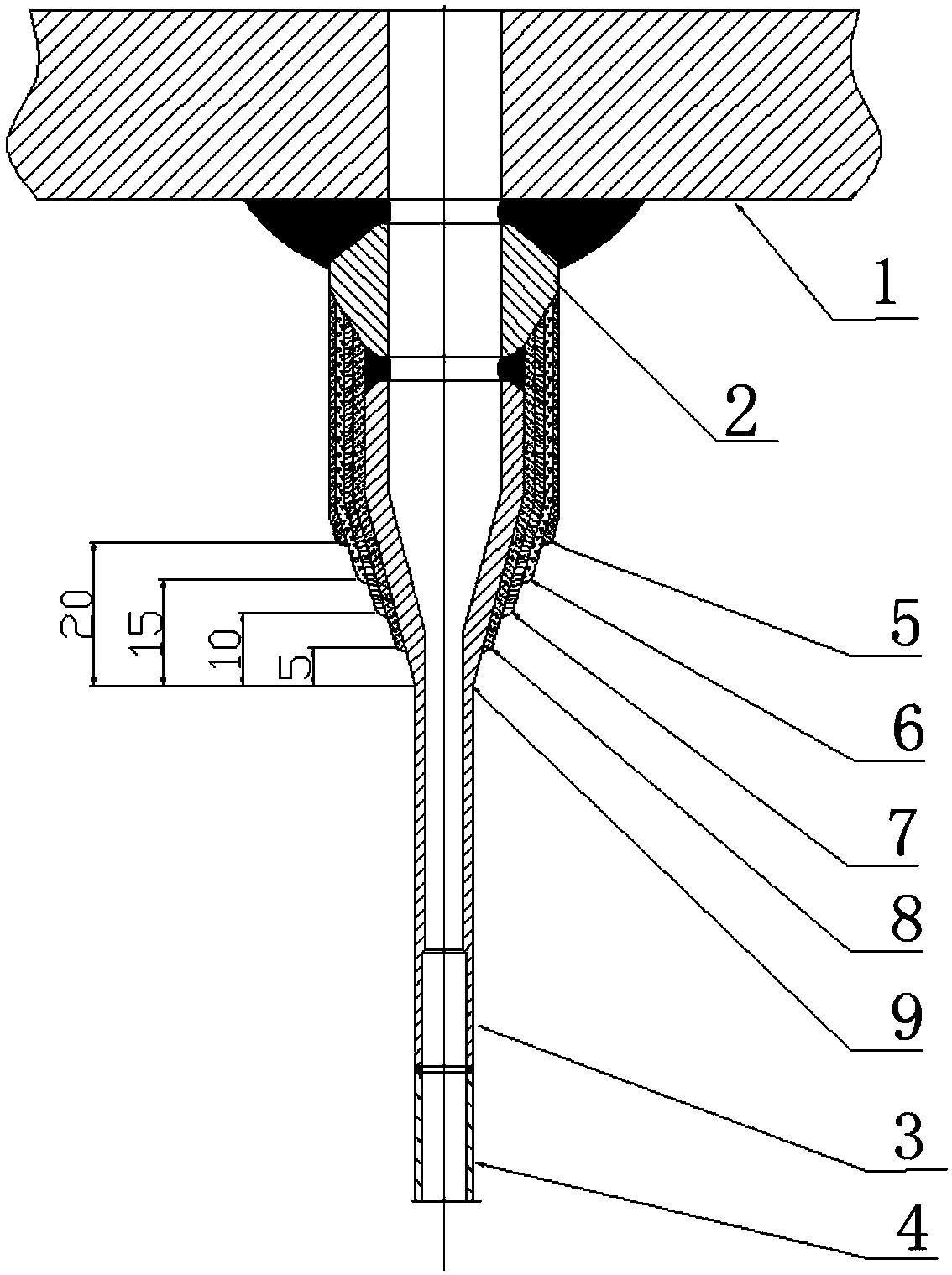

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] Such as image 3 As shown, a heavy water reactor main pipeline branch pipe joint surfacing welding repair structure, including the main pipeline 1, pipe seat 2, adapter 3, instrument pipe 4, surfacing layer cover layer 5, surfacing layer third layer 6, surfacing Layer 2 Layer 7 and Overlay Layer 1 Layer 8. The upper end of the pipe base 2 is connected to the lower end of the opening where the main pipe 1 connects to the branch pipe, and the pipe base 2 and the main pipe 1 are welded by argon arc welding. The upper end of the adapter 3 is connected to the lower end of the tube base 2, and the adapter 3 and the tube base 2 are welded by argon arc welding. The upper end of the instrument pipe 4 is connected to the lower end of the adapter 3, and the instrument pipe 4 and the adapter 3 are automatically welded in all positions. Surfacing welding i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com