A corrugated pipe with different deformation strengthening layers

A corrugated pipe and strengthening layer technology, applied in the field of pipeline compensation, can solve the problems of small deformation rate and limited strengthening effect, and achieve the effects of saving material usage, low stress corrosion sensitivity, and improving the overall pressure bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

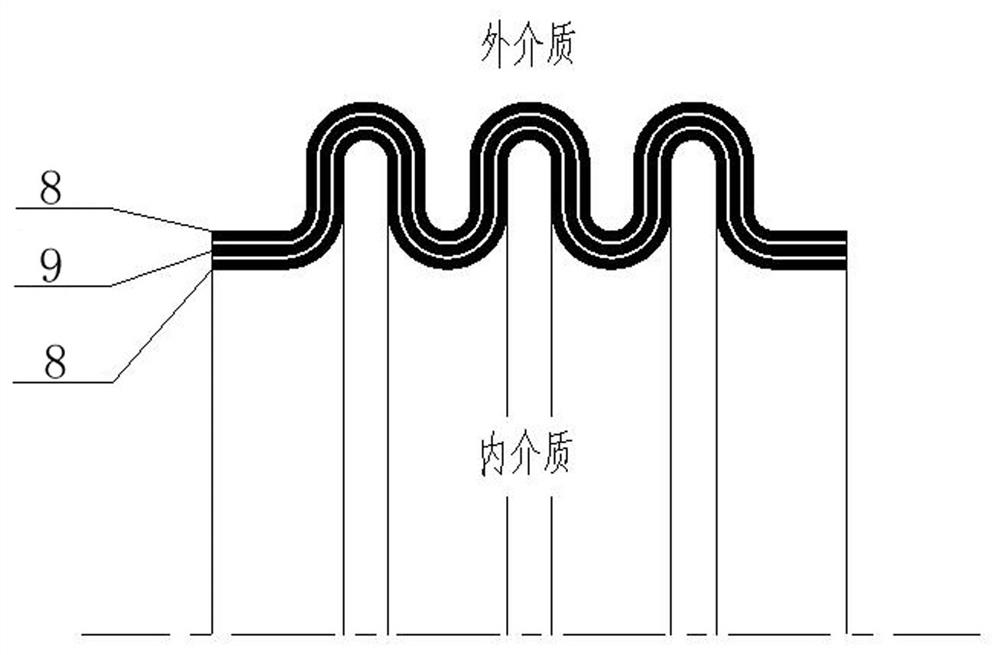

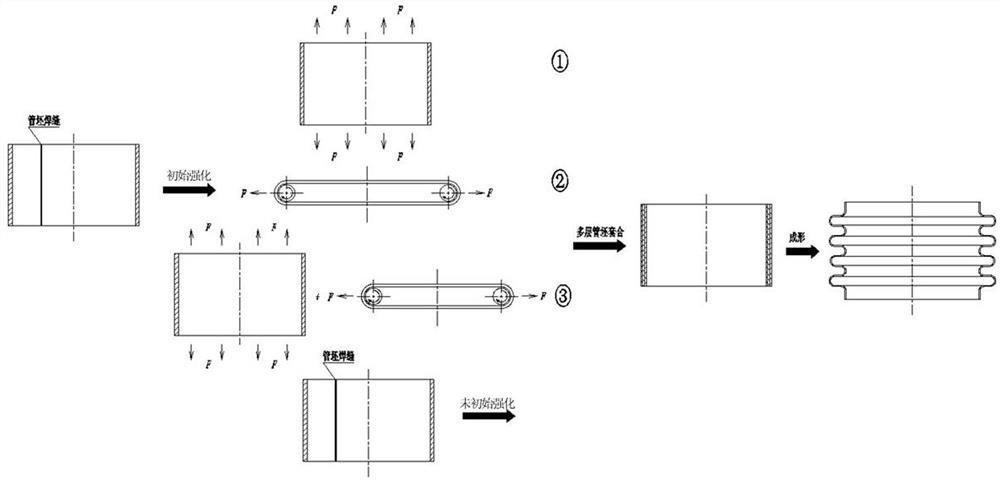

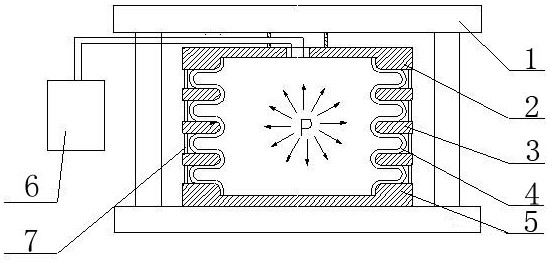

[0014] A corrugated pipe with different deformation strengthening layers, which is used for hydraulic corrugation forming of multi-layered corrugated pipe blanks, the corrugated pipe blanks located in the innermost and outermost layers are not initially The corrugated pipe blank between the inner layers is initially strengthened, and the process of initial strengthening is to carry out uniform axial stretching and / or circumferential stretching of the corrugated pipe blank. Such as figure 1 As shown, the outermost and innermost corrugated pipe blanks are the uninitiated strengthening layer, and the middlemost corrugated pipe blank is the initial strengthening layer. The initial strengthening layer is the strength base, which only bears pressure, and the layer in contact with the corrosive medium is a non-initial strengthening layer. The non-initial strengthening layer can be placed on the inner layer or the outer layer alone, or it can be arranged on the inner layer and the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com