Efficient grinding device for aluminum lipstick tube

A lipstick tube, high-efficiency technology, applied in the direction of grinding drive devices, grinding machines, manufacturing tools, etc., can solve the problems of low efficiency and low grinding precision, and achieve the effect of remarkable effect, simple structure, continuous and efficient grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

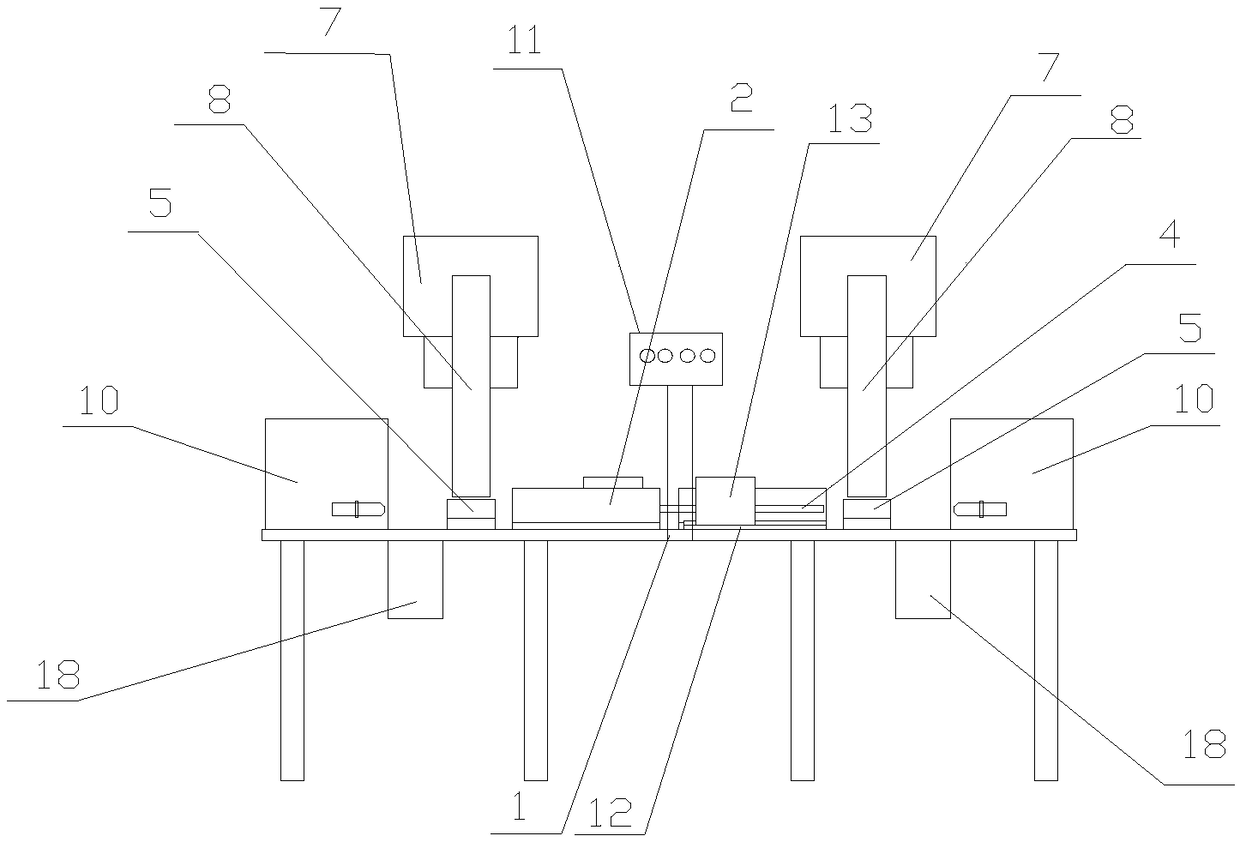

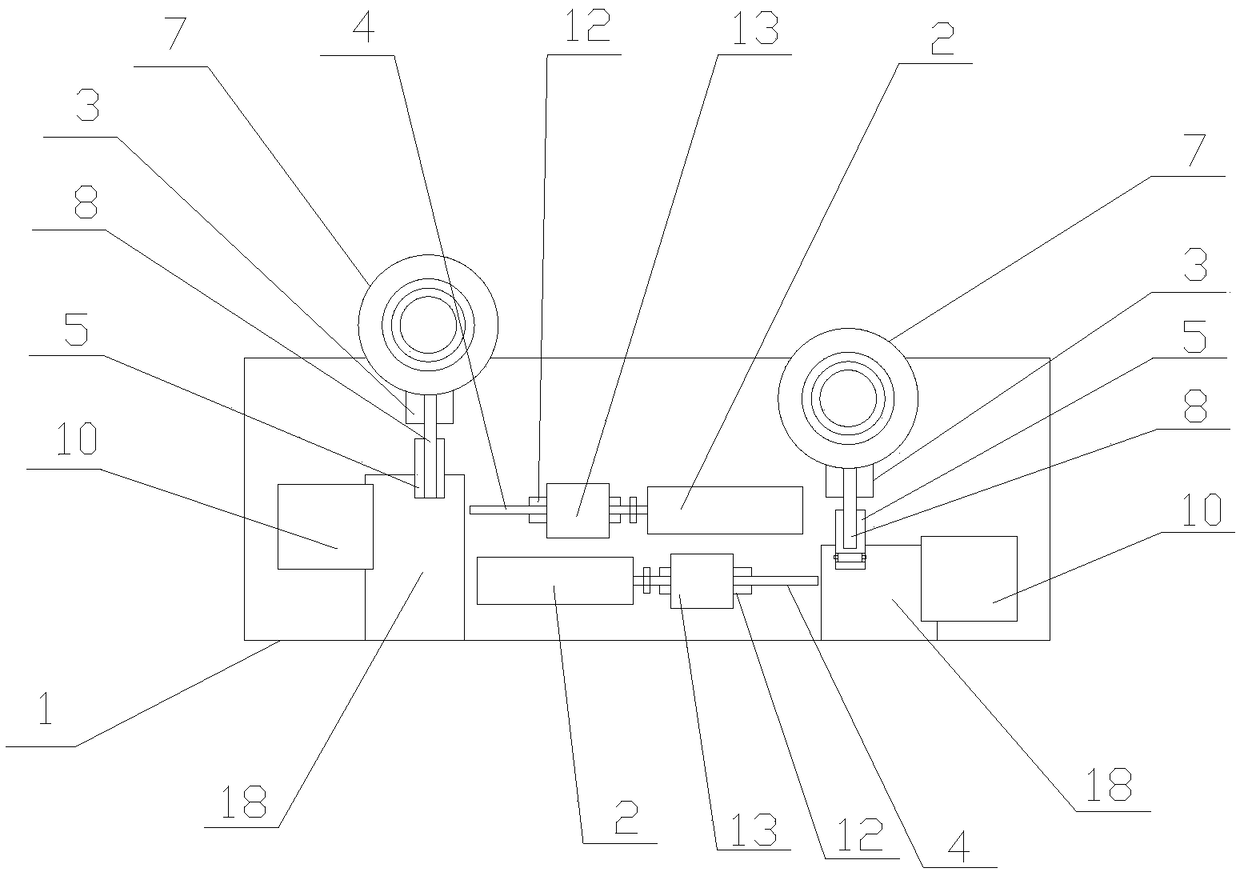

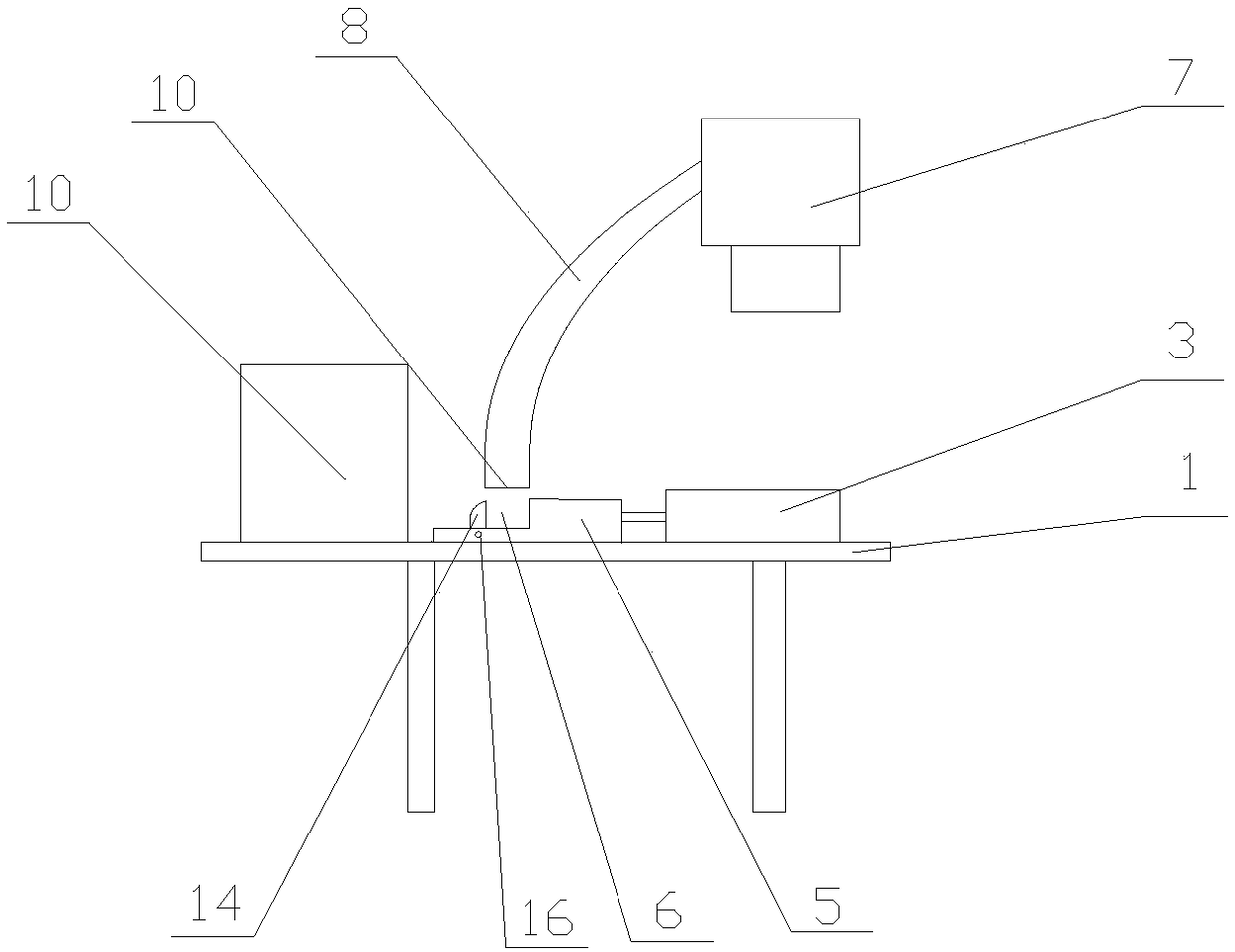

[0020] like Figure 1 to Figure 4 As shown, a high-efficiency polishing device for aluminum lipstick tubes includes a machine tool 1, a first air pump 2 and a second air pump 3 are fixedly arranged on the machine tool, a push rod 4 is arranged at one end of the first air pump 2, and a push rod 4 is arranged at one end of the second air pump. 3. One end is provided with a push block 5, and the push rod 4 and the push block 5 will intersect vertically after being pushed out. The end of the push block 5 far away from the second air pump 3 is provided with a three-side open accommodation tank 6, and a top of the second air pump 3 is provided with a The vibrating plate 7, the side wall of the vibrating plate 7 is provided with a downward feeding pipeline 8, the feeding pipeline 8 is made of high-hardness modified plastic, and the discharge port 9 of the feeding pipeline 8 fits the accommodation of the second air pump 3 in the retracted state At the upper end of the groove 6, when t...

Embodiment 2

[0022] like Figure 1 to Figure 4 As shown, a high-efficiency polishing device for aluminum lipstick tubes includes a machine tool 1, a first air pump 2 and a second air pump 3 are fixedly arranged on the machine tool, a push rod 4 is arranged at one end of the first air pump 2, and a push rod 4 is arranged at one end of the second air pump. 3. One end is provided with a push block 5, and the push rod 4 and the push block 5 will intersect vertically after being pushed out. The end of the push block 5 far away from the second air pump 3 is provided with a three-side open accommodation tank 6, and a top of the second air pump 3 is provided with a The vibrating plate 7, the side wall of the vibrating plate 7 is provided with a downward feeding pipeline 8, the feeding pipeline 8 is made of high-hardness modified plastic, and the discharge port 9 of the feeding pipeline 8 fits the accommodation of the second air pump 3 in the retracted state The upper end of the groove 6, when the ...

Embodiment 3

[0024] like Figure 1 to Figure 4 As shown, a high-efficiency polishing device for aluminum lipstick tubes includes a machine tool 1, a first air pump 2 and a second air pump 3 are fixedly arranged on the machine tool, a push rod 4 is arranged at one end of the first air pump 2, and a push rod 4 is arranged at one end of the second air pump. 3. One end is provided with a push block 5, and the push rod 4 and the push block 5 will intersect vertically after being pushed out. The end of the push block 5 far away from the second air pump 3 is provided with a three-side open accommodation tank 6, and a top of the second air pump 3 is provided with a The vibrating plate 7, the side wall of the vibrating plate 7 is provided with a downward feeding pipeline 8, the feeding pipeline 8 is made of high-hardness modified plastic, and the discharge port 9 of the feeding pipeline 8 fits the accommodation of the second air pump 3 in the retracted state The upper end of the groove 6, when the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap