Fabricated frame structure damping reinforcing device and construction method thereof

A frame structure and reinforcement device technology, applied in the direction of earthquake resistance, building components, building structures, etc., can solve the problems of easy leakage of viscous liquids, weakened energy consumption capacity, and difficulty in controlling the threshold, so as to achieve easy assembly and disassembly, Good shock absorption performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

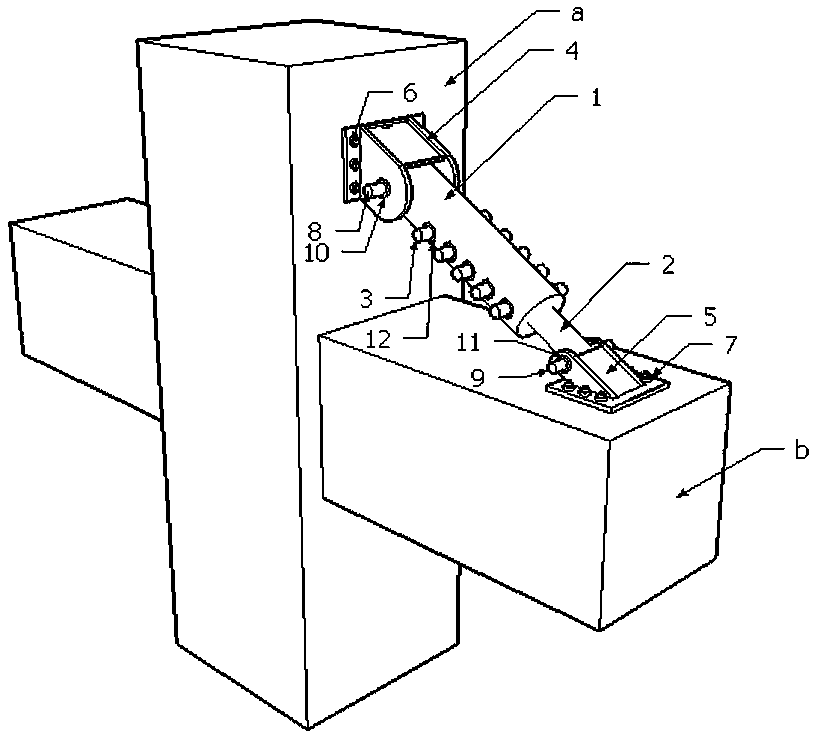

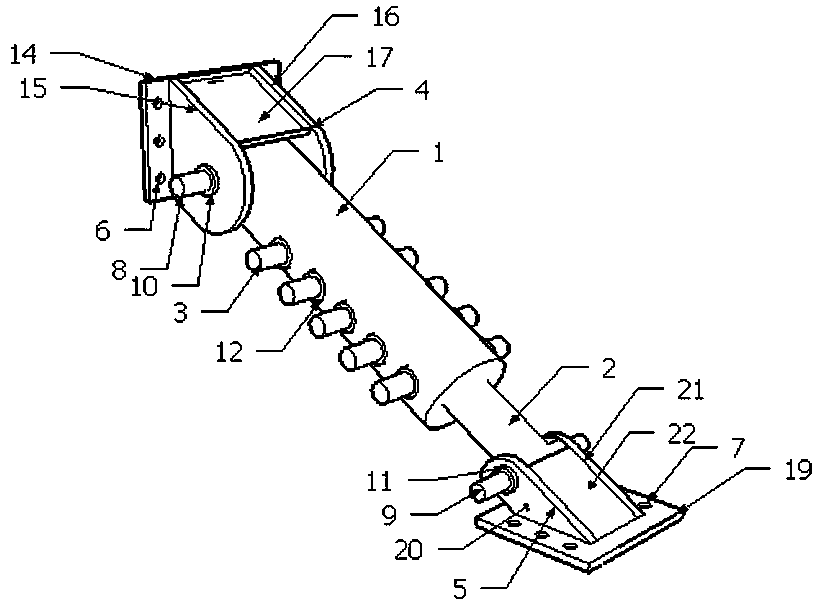

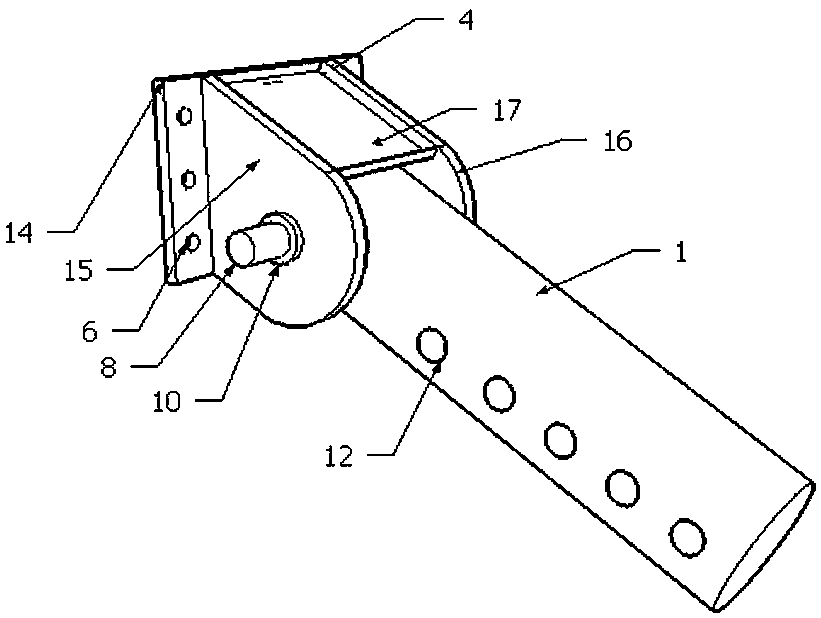

[0029] In order to explain the present invention more clearly, the present invention will be further described below in conjunction with the drawings and embodiments. Obviously, the drawings listed below are only some specific embodiments of the present invention.

[0030] Such as Figure 1-7 As shown, the present invention is an assembled frame structure shock absorbing reinforcement device, comprising a first hinged seat 4, a second hinged seat 5, a first rod body 1 and a second rod body 2, the first hinged seat 4, the second hinged seat The seat 5 is used to be fixedly connected to the column a and the beam b of the beam-column node of the assembled frame structure; the upper end of the first rod body 1 is hinged to the first hinge seat 4 through the first hinge shaft 8, and the first rod body 1 The shaft of the shaft is axially spaced apart from several first radial through holes 12; the lower end of the second shaft 2 is hinged to the second hinge seat 5 through the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com