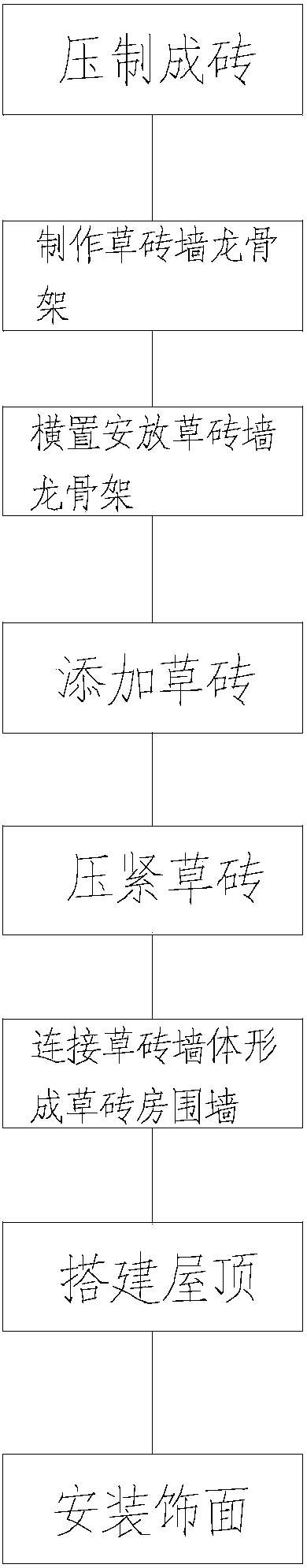

Straw brick house construction technology

A construction technique, straw brick technology, applied in the direction of building components, walls, buildings, etc., can solve problems such as fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

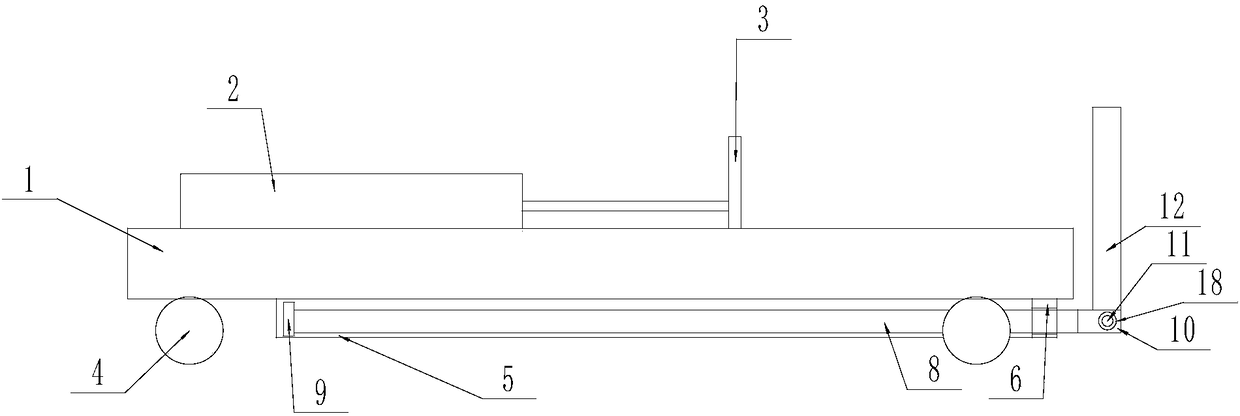

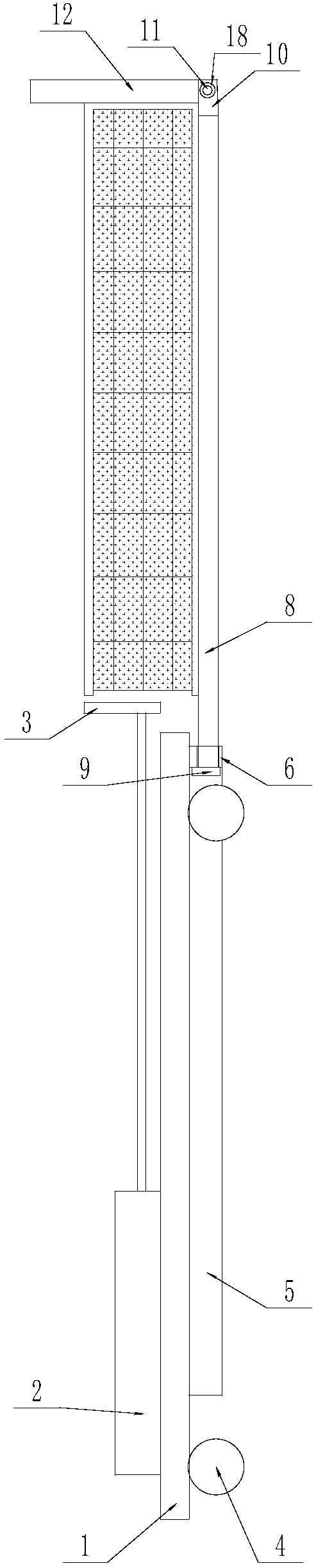

Image

Examples

Embodiment 1

[0038] Embodiment 1: add ribs in the straw bricks, such as steel bars and other profiles, and then stack the straw bricks for compaction. By adding steel bars, the straw bricks can mainly bear the tensile stress during the compaction of the straw bricks. Due to the effect of the ribs, the deformed steel bar has a greater bonding capacity with the grass brick, so it can better withstand the action of external force.

Embodiment 2

[0039] Embodiment 2, when the frame of the straw brick wall is a metal profile, the connection between the two straw brick wall dragon frames can be carried out by the most common welding method, and the connection method can also be realized by setting the connecting piece. When the keel frame is a wood profile, it can only be connected by setting connectors. When the grass brick wall is only used as a vertical wall, it can be connected by using ordinary connectors such as screws and bolts to cooperate with connectors and hinge rotating connectors. , when the straw brick wall is used in the jump floor of a multi-storey building, because the grass brick wall not only bears the prestress brought by the building, but also bears the gravity of the body's own weight, The selected connector needs to bear the multi-layer force of prestress and human gravity, so the plug-in connector similar to claim 7 is often used, and this kind of connection can bear the multi-layer force of prestr...

Embodiment 3

[0040] Embodiment three, such as Figure 7 , the upper and lower ends and the center of the two-story keel frame are equipped with supporting steel plates or wooden boards, forming an H-shaped steel structure with the keel frame. This kind of keel is suitable for floor slabs in multi-storey buildings, which can effectively and greatly improve Resist its own gravity and various loads on it.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com