One-way impacter based on turbine and spring

A technology of impactor and turbine, applied in the field of one-way impactor, can solve the problems of drilling tool failure, ROP and other problems, and achieve the effect of improving ROP, reasonable design and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

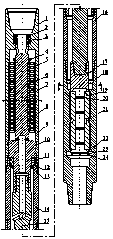

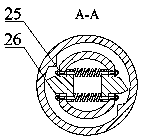

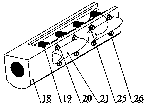

[0014] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

[0015] Referring to the accompanying drawings, the one-way impactor based on turbine and spring is characterized in that: the one-way impactor based on turbine and spring is composed of upper joint 1, turbine assembly, transmission assembly, conversion joint 16, impact assembly It is composed of a lower joint 18; the upper end of the upper joint 1 is connected to the drill pipe, and the lower end is connected to the transmission housing 14 in the transmission assembly; the turbine assembly includes a bearing cover 2, an angular contact ball bearing 3, and a retaining ring a4 , transmission key 5, turbine rotor 6, turbine stator 7, turbine shaft 8, positioning ring 9, rectangular sealing ring 10, cylindrical roller bearing 11, thrust ball bearing 12, anti-drop retaining ring b13, bearing cover 2 and turbine shaft 8 are matched through threads, two angular con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com