Liftable spinning machine

A textile machine, bottom-fixed technology, applied in mechanical equipment, supporting machines, engine bases, etc., can solve problems such as reducing textile work efficiency, textile machine adjustment, discomfort, etc., to facilitate movement, improve efficiency, and improve balance performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

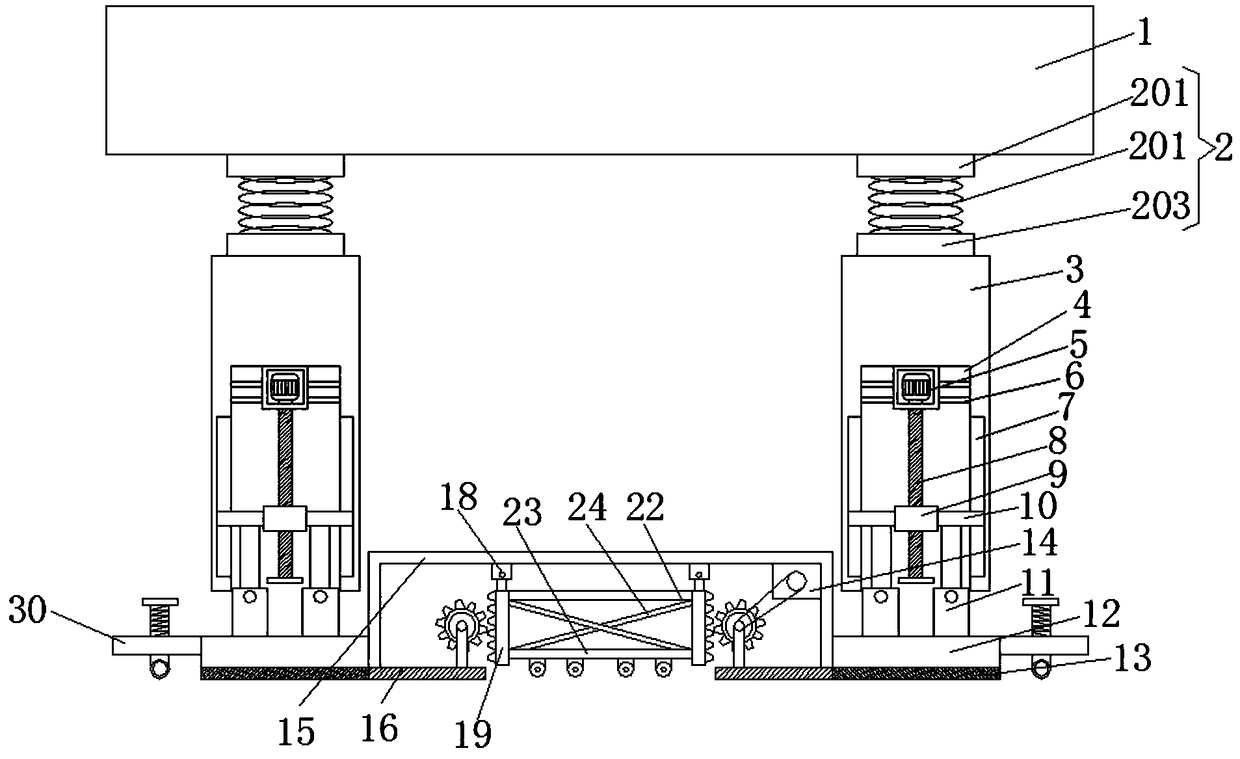

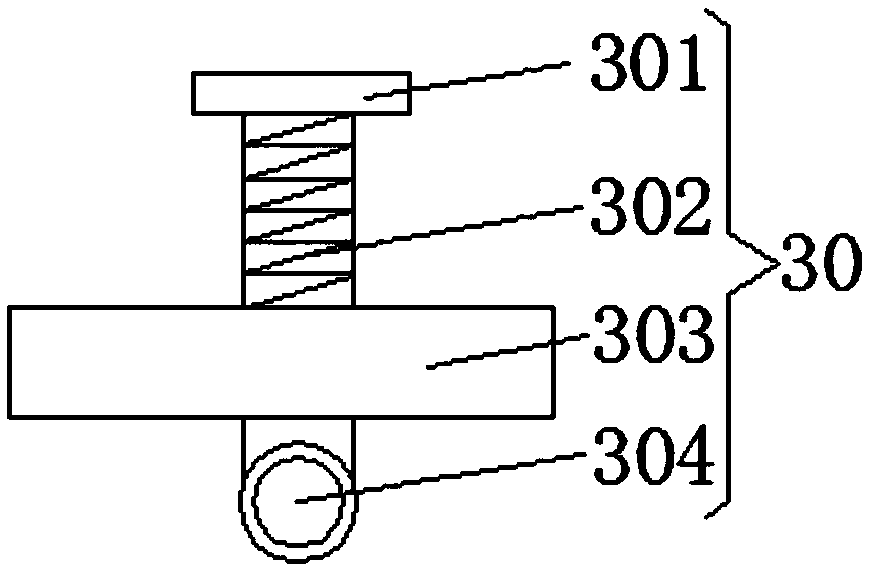

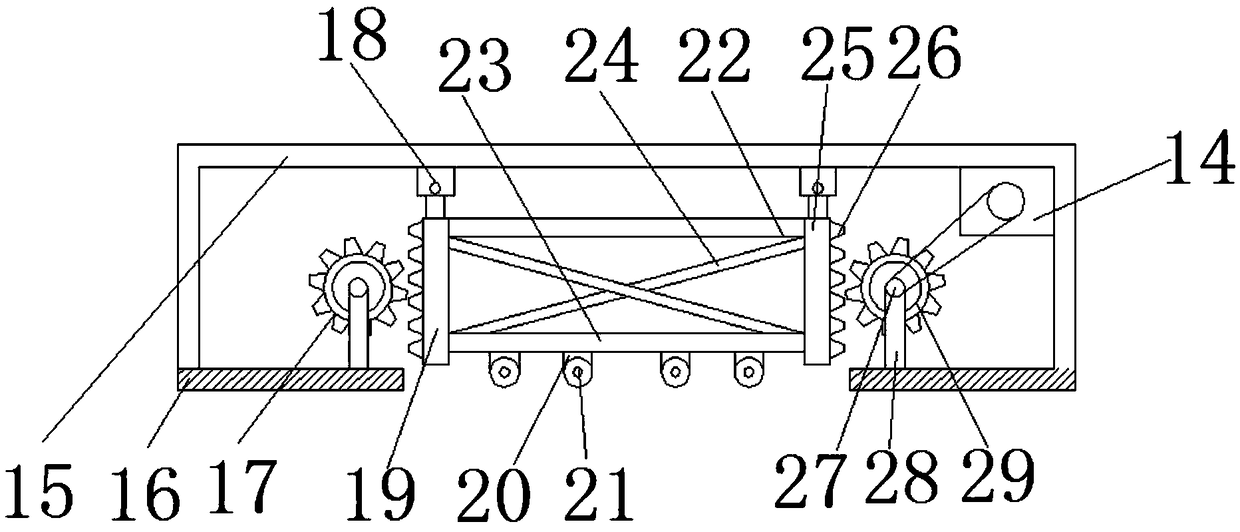

[0023] Embodiments of the present invention provide a liftable textile machine, such as Figure 1-3 As shown, including the workbench 1, the bottom of the workbench 1 is fixedly equipped with a shock absorber 2. By setting the shock absorber 2, the vibration generated by the textile machine can be absorbed, which greatly improves the stability of the textile machine and greatly prolongs the working life of the textile machine. The service life of textile machine, damping device 2 comprises upper fixed plate 201, and the top of upper fixed plate 201 is fixedly installed with the bottom of workbench 1, and the lower side of upper fixed plate 201 is provided with lower fixed plate 203, and the bottom of upper fixed plate 201 The bottom is fixedly equipped with shock absorbing spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com