Fast-steering-mirror large-angle rotating mechanism based on cross spring bearing

A cross spring bearing, fast control technology, applied in installation, optics, instruments, etc., can solve the problems of large inertia and friction torque of shafting structure, nonlinear control system, slow system response, etc., to increase motor reserve torque, The effect of wide angle range and high working bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

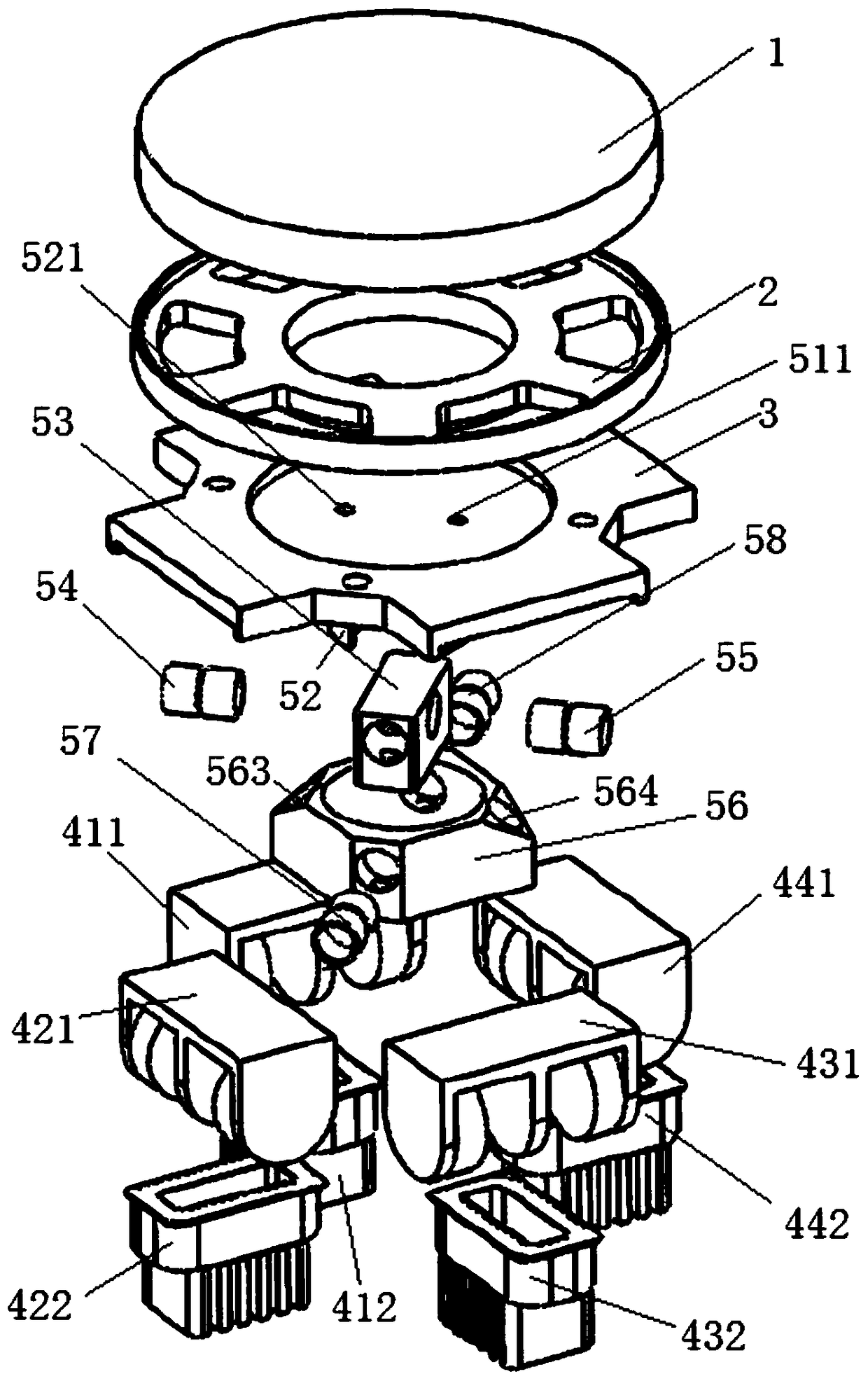

[0023] Such as figure 1 ,figure 2, image 3 , Figure 4 , Figure 5 with Image 6 Shown, the fast control reflector large-angle rotation mechanism based on cross spring bearing of the present invention comprises mirror holder support 2, motor mounting frame 3 and four linear voice coil motors that are distributed around the motor mounting frame, supporting mechanism.

[0024] The mirror support bracket 2 is fixed on the motor mounting frame 3 for supporting and fixing the mirror 1 .

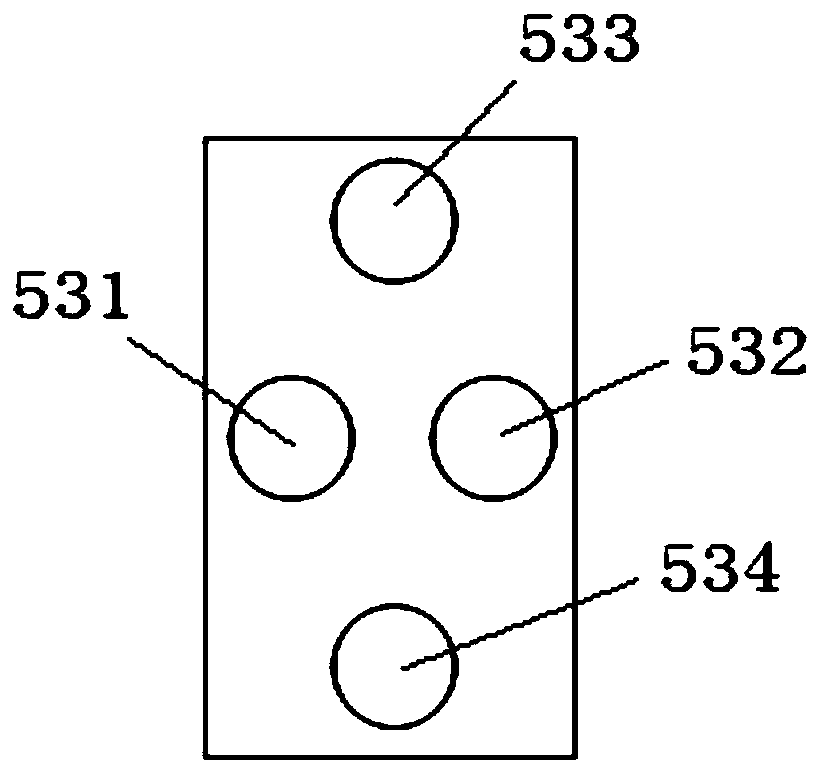

[0025] The motor mounting frame 3 is a square, circular, rectangular or other shape, and four bosses 31, 32, 33, 33, 33, 34. The directions of the linear voice coil motor 41 and the linear voice coil motor 43 are parallel, and the directions of the linear voice coil motor 42 and the linear voice coil motor 44 are parallel; the directions of two adjacent linear voice coil motors are perpendicular to each other. Linear voice coil motor magnets 411, 421, 431, 441 are installed and fixed under t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com