Heat dissipation assembly for motor housing, and motor housing comprising same

A technology for motor casing and heat dissipation components, which is applied in the directions of electric components, electrical components, casing/cover/support, etc., can solve the problems of difficult processing of closed-cavity pipelines, increased motor weight and design difficulty, and high cost of motor casings , to achieve the effect of low manufacturing difficulty and cost, simple and easy assembly, and good sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is further illustrated by the following examples to better illustrate the present invention. It should also be understood that the following examples are only used to further illustrate the present invention, and should not be construed as limiting the protection scope of the present invention. Some non-essential improvements and adjustments made by those skilled in the art according to the above contents of the present invention all belong to the present invention scope of protection.

[0028] Also, the following terms may be defined in consideration of functions in the present invention, and may be interpreted in different ways according to user's and operator's intentions. Therefore, the terms defined here should be interpreted based on the contents throughout the specification.

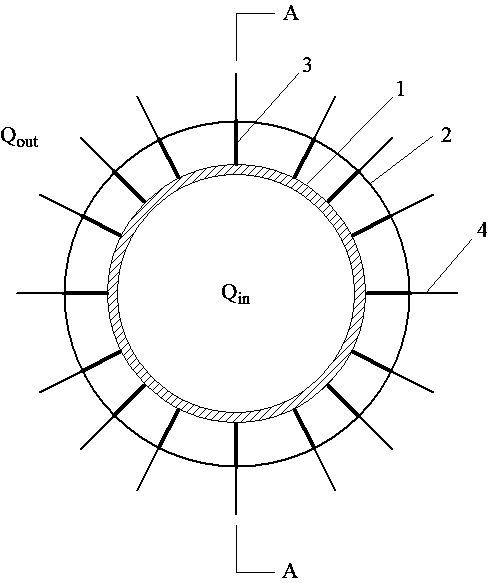

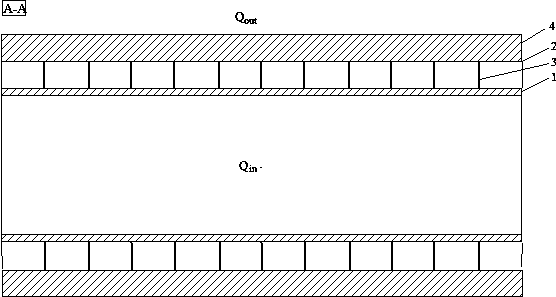

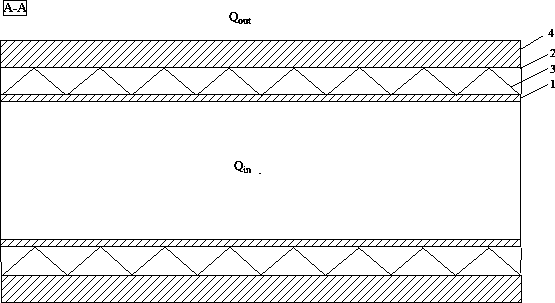

[0029] see figure 1 and figure 2 , The heat dissipation assembly of the motor housing of the present invention includes a three-layer structure of a heat pipe 3 , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com