New-type camera module

A camera module and lens assembly technology, which is applied in image communication, optical filters for photography, instruments, etc., can solve the problems of increasing the weight of the overall module, affecting the appearance, and high cost, so as to reduce the water absorption expansion rate and improve heat dissipation Effect, effect to ensure the strength of the module

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the creative features, technical means and objectives of the present invention easy to understand, the present invention is further described below in conjunction with specific embodiments.

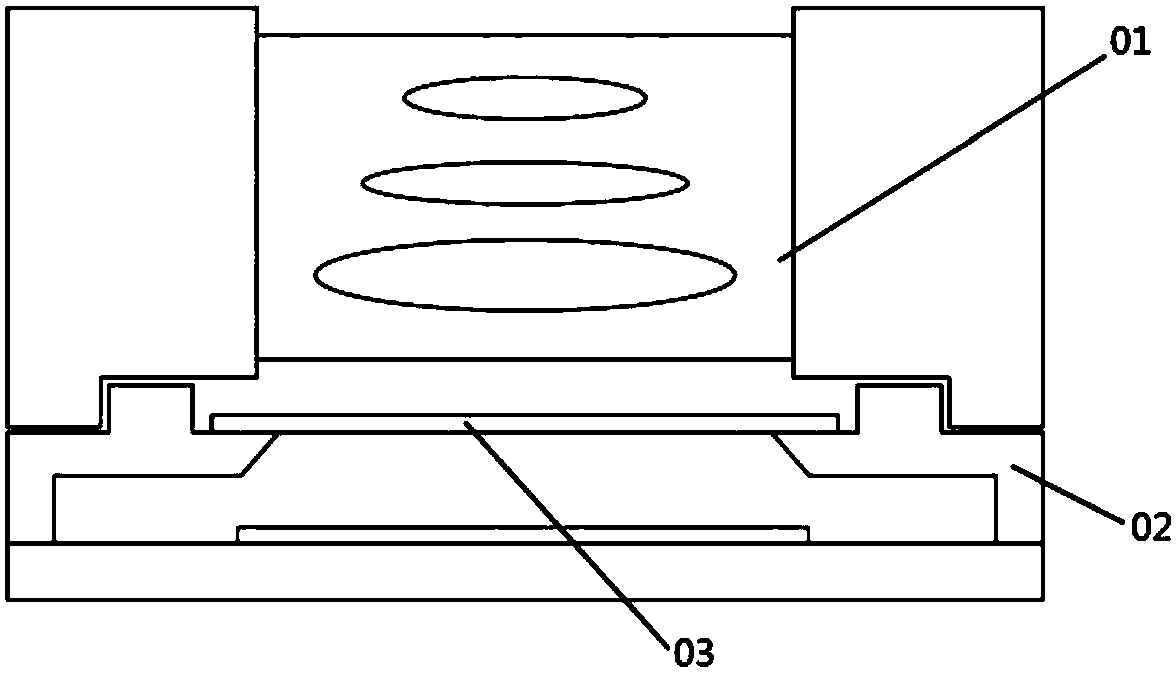

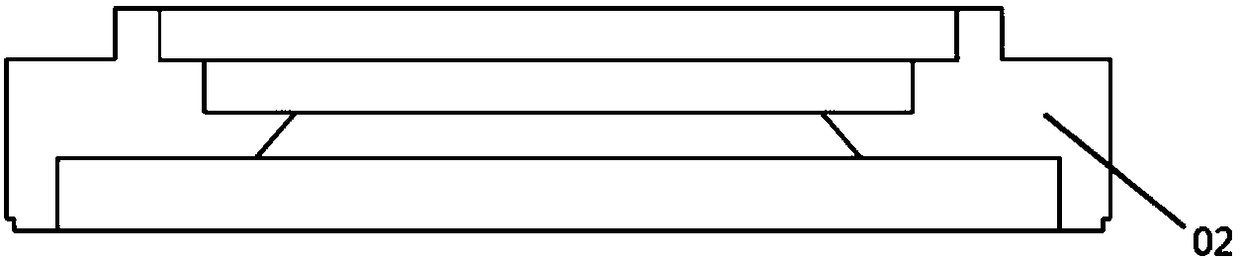

[0028] see figure 1 , is a structure diagram of the module in the prior art, the base 02 accepts the lens assembly 01, and the light passes through the lens assembly 01 and then passes through the filter 03. Such as figure 2 As shown, the base 02 is made of integral plastic, so it has technical defects as described in the background art.

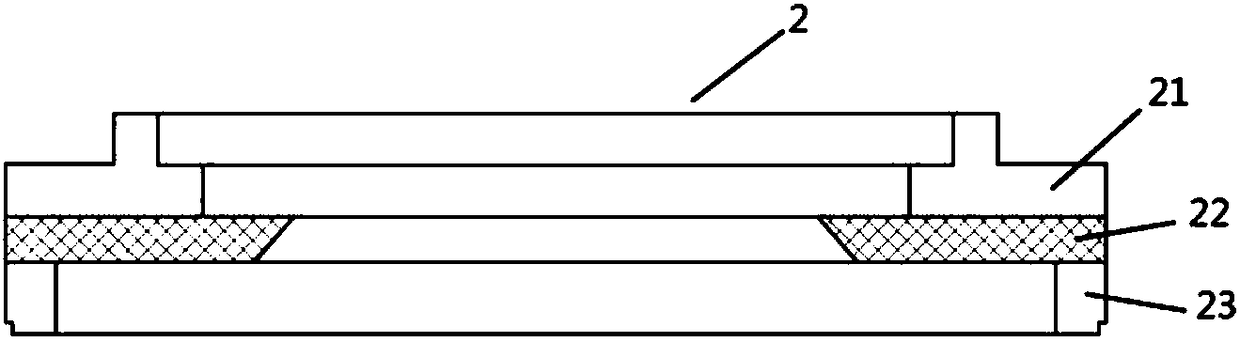

[0029] Such as Figure 3-7 As shown, it is a schematic structural view of the base 2 of the present invention, the base 2 includes a lens receiving portion 21, an optical filter supporting portion 22 and a cylindrical portion 23; the optical filter supporting portion 22 is made of a metal material and formed integrally with the lens receiving portion 21 and the cylindrical portion 23 through an integral molding process. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com