External liquid dispersing device

A liquid dispersion, external technology, applied in transportation and packaging, mixers, mixing methods, etc., can solve the problems of difficult maintenance, unstable product quality, long maintenance time, etc., to reduce construction costs and operating costs, active dispersion The effect of high efficiency and improved safety and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the following embodiments will specifically illustrate the external liquid dispersion device of the present invention in conjunction with the accompanying drawings.

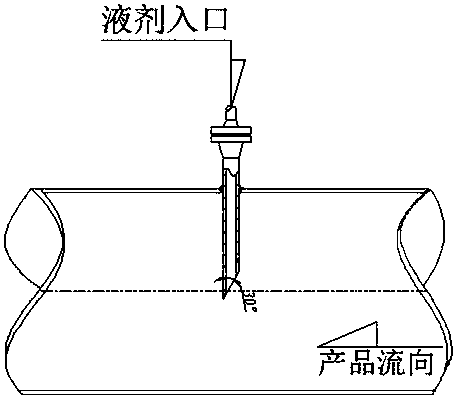

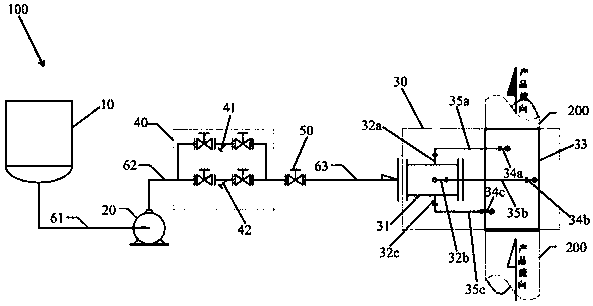

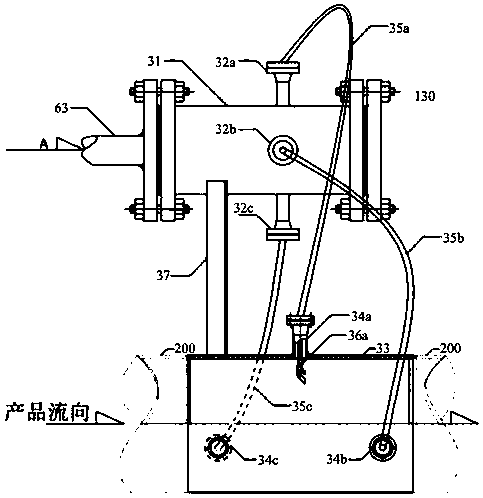

[0028] Such as image 3 As shown, the external liquid dispersing device 100 is used to inject auxiliary liquid reagents or water into the medium main pipe 200, and is suitable for regions in the south or north where the spring, autumn and summer temperatures are relatively suitable, and the auxiliary liquid reagents or water do not need to be kept warm. The external liquid dispersing device 100 includes: a liquid energy storage tank 10 , a booster pump 20 and a disperser 30 . The liquid energy storage tank 10 is connected to the booster pump 20 through the pipeline 61 , and the booster pump 20 is connected to the disperser 30 through the pipelines 62 and 63 .

[0029] The liquid agent st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com