Remote control high-pressure cleaning machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

[0034] It should be understood that terms such as "having", "comprising" and "including" used herein do not exclude the presence or addition of one or more other elements or combinations thereof.

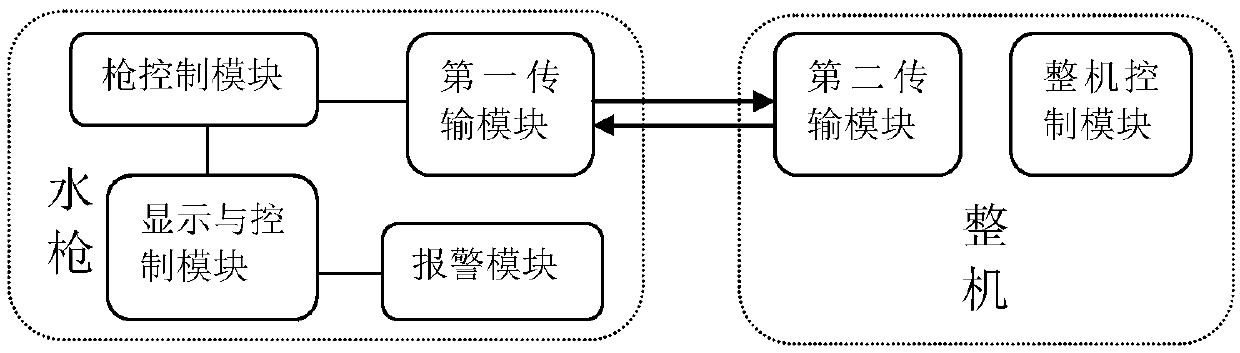

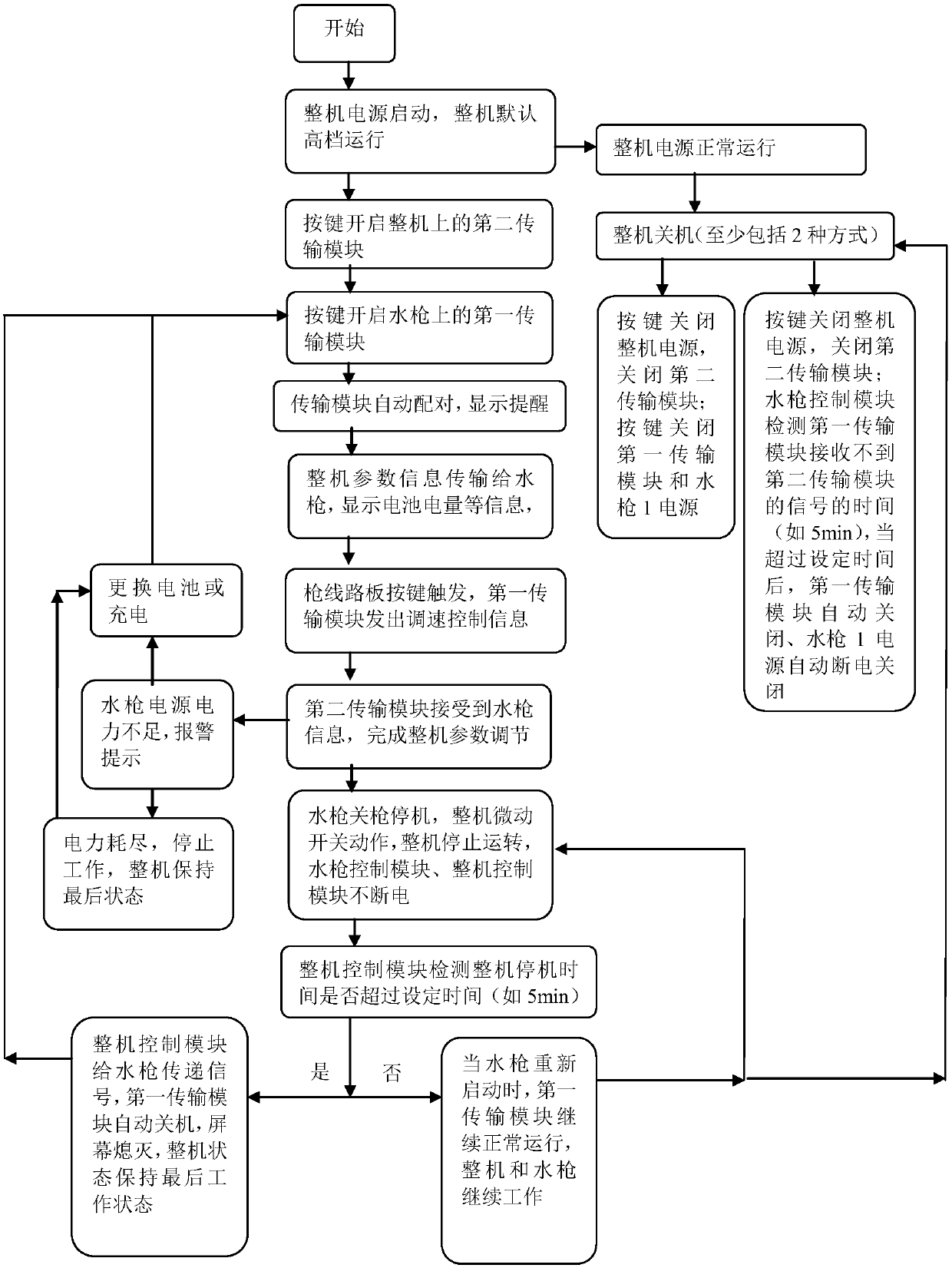

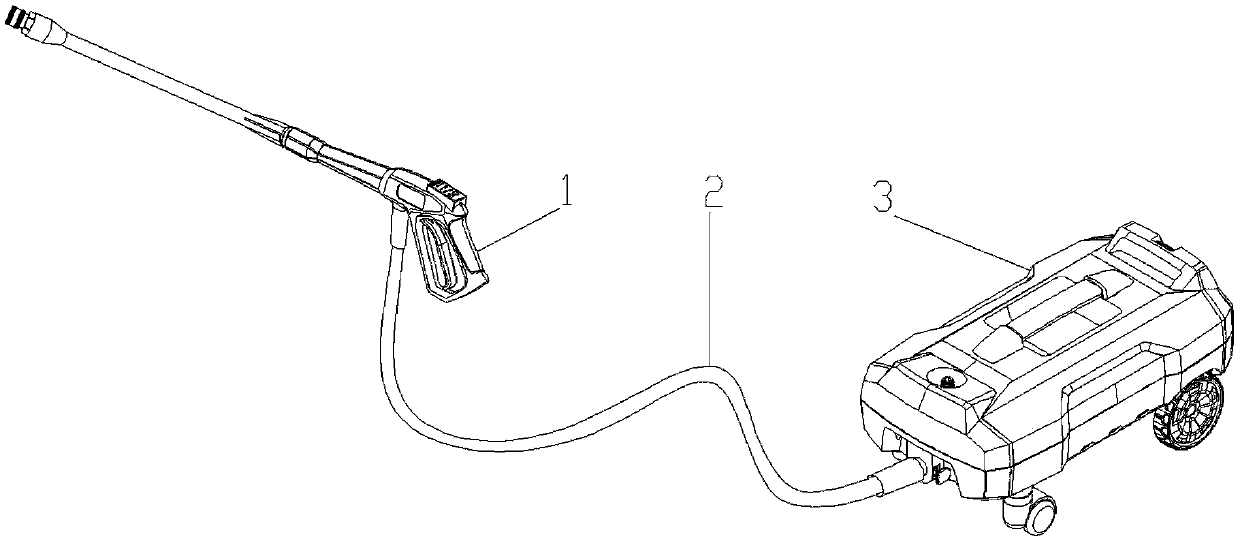

[0035] A remote-controlled high-pressure cleaning machine in this embodiment includes a water gun 1 and a complete machine 3, and also includes a transmission module for establishing a communication connection between the water gun 1 and the complete machine 3. The water gun 1 is provided with a display and control module.

[0036] The complete machine 3 provides a high-pressure water source for the water gun 1 through the water pipe 2 .

[0037] In one embodiment, the display and control module is a controllable display screen.

[0038] In one embodiment, further, the controllable display ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com