Selective laser melting method

A laser melting and selective technology, used in the improvement of process efficiency, additive manufacturing, additive processing, etc., can solve the problems of cumbersome raw material recycling, waste processing raw materials, increase the scope of application, etc., to avoid raw material recycling and processing. Cumbersome, avoid low processing efficiency, and increase the effect of the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

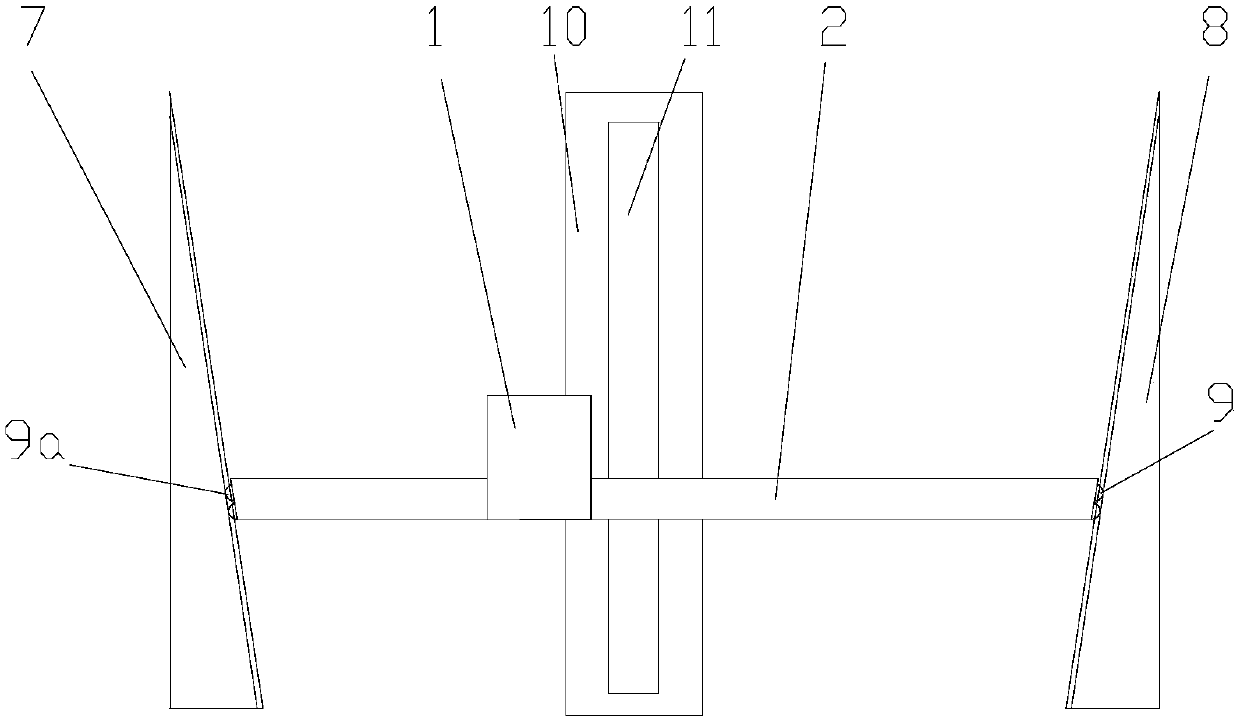

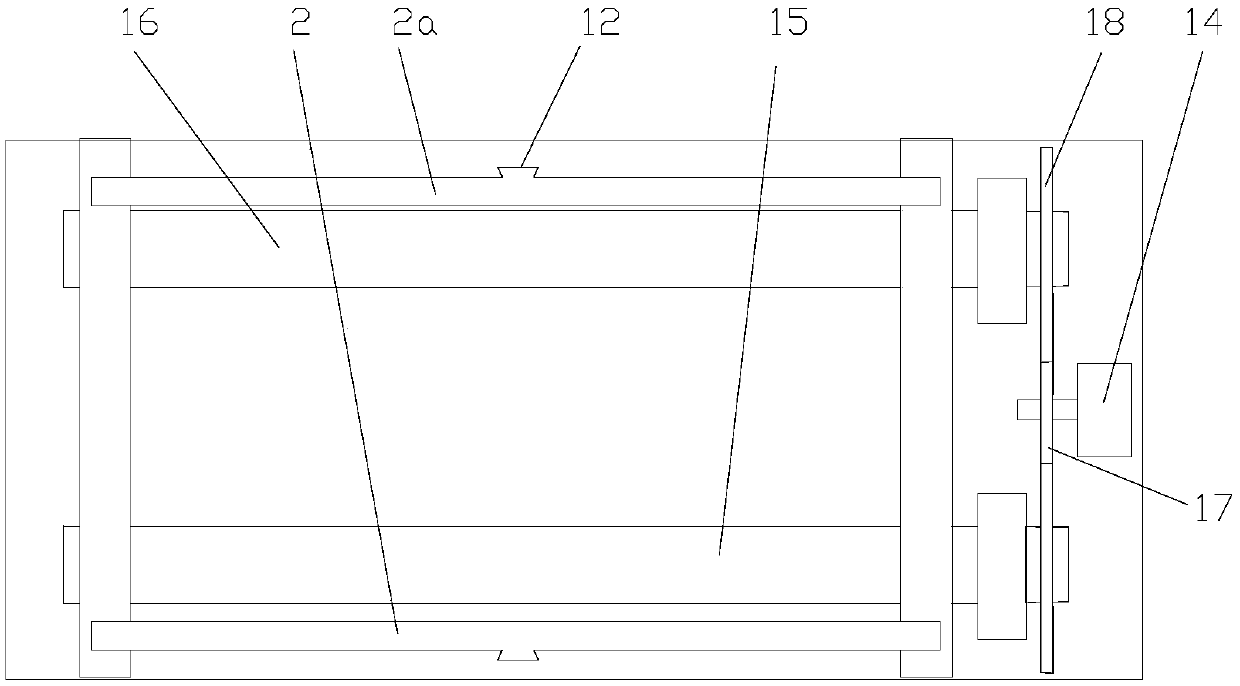

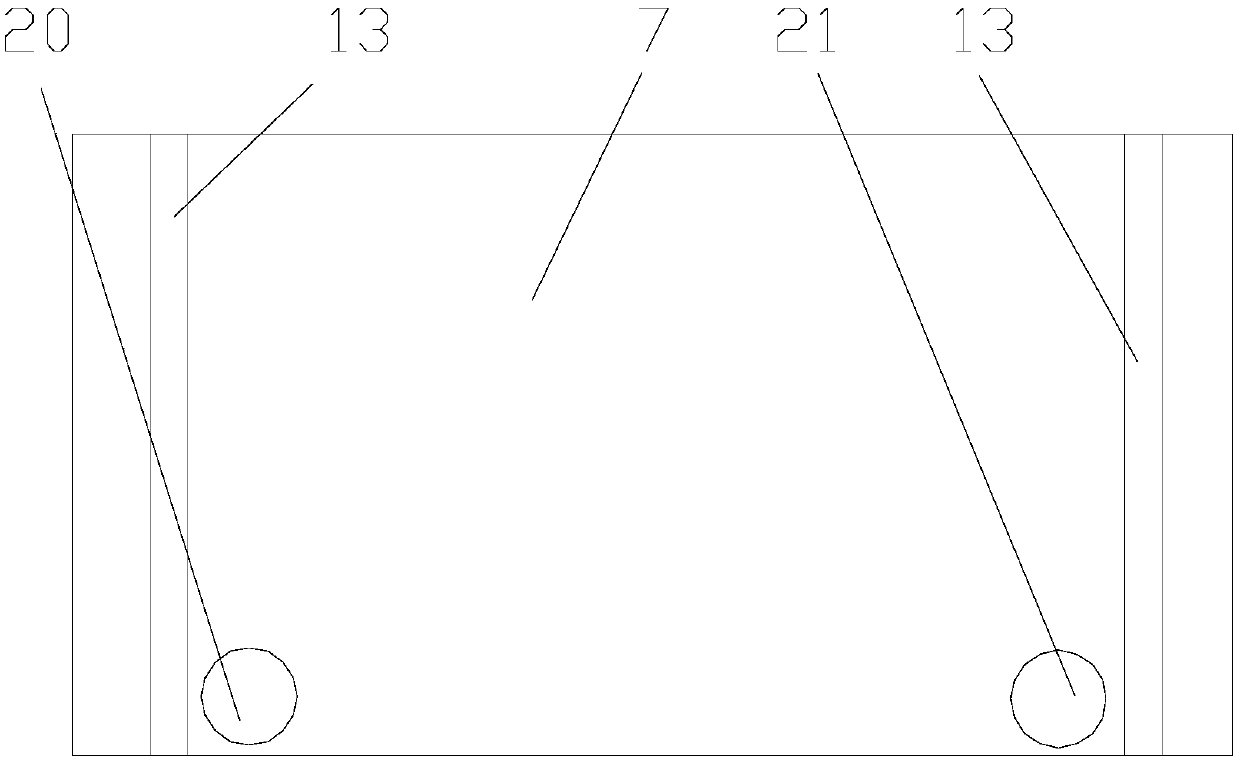

[0028] figure 1 It is a schematic structural diagram of the present invention, as shown in the figure, a selective laser melting method in this embodiment, this embodiment also discloses a selective laser melting method, including the following steps:

[0029] (1) Use a selective laser melting system to lay a layer of metal powder on the substrate;

[0030] (2) On the current layer of metal powder in step (1), an outer ring layer b is formed by laser melting according to the size of the workpiece;

[0031] (3) laser melting in the outer ring layer of step (2) to form the workpiece sheet a;

[0032] (4) Spread a layer of metal powder on the outer ring layer and the sheet of the workpiece by using a powder spreading device, and repeat steps (2) and (3) in a cycle until the workpiece is completed as a whole.

[0033] In this embodiment, in the step (2), the ring line width of the ring layer of the outer ring is 5-1.5 mm; preferably 1 mm.

[0034] In this embodiment, in step (2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com