Unsupported 3D printing system and method

A 3D printing, unsupported technology, applied in the field of 3D printing technology, can solve the problems of unsatisfactory printing of precision objects, rough surface quality of parts, high equipment cost, etc., and achieve the effect of saving labor costs, high printing accuracy and fast printing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

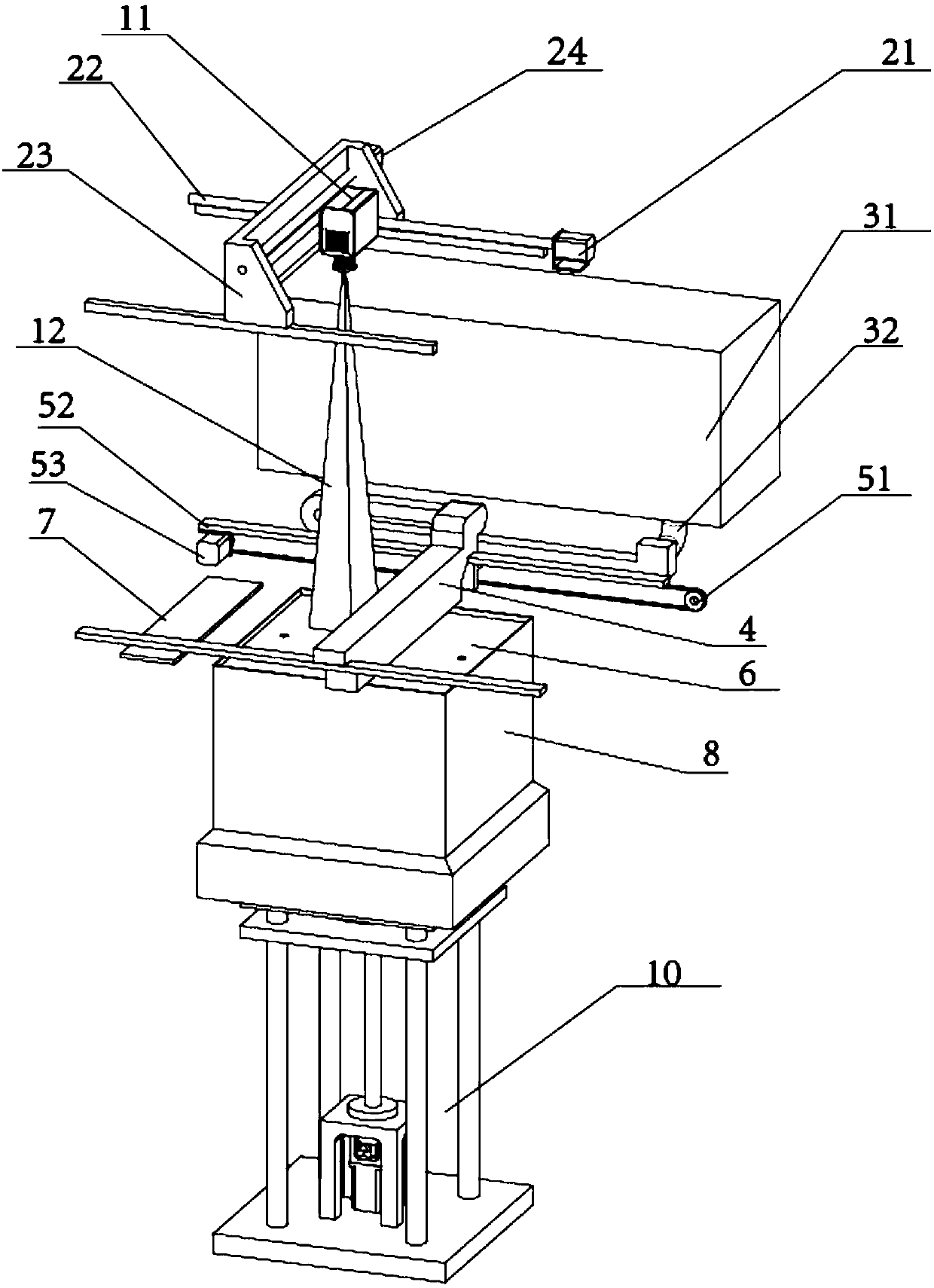

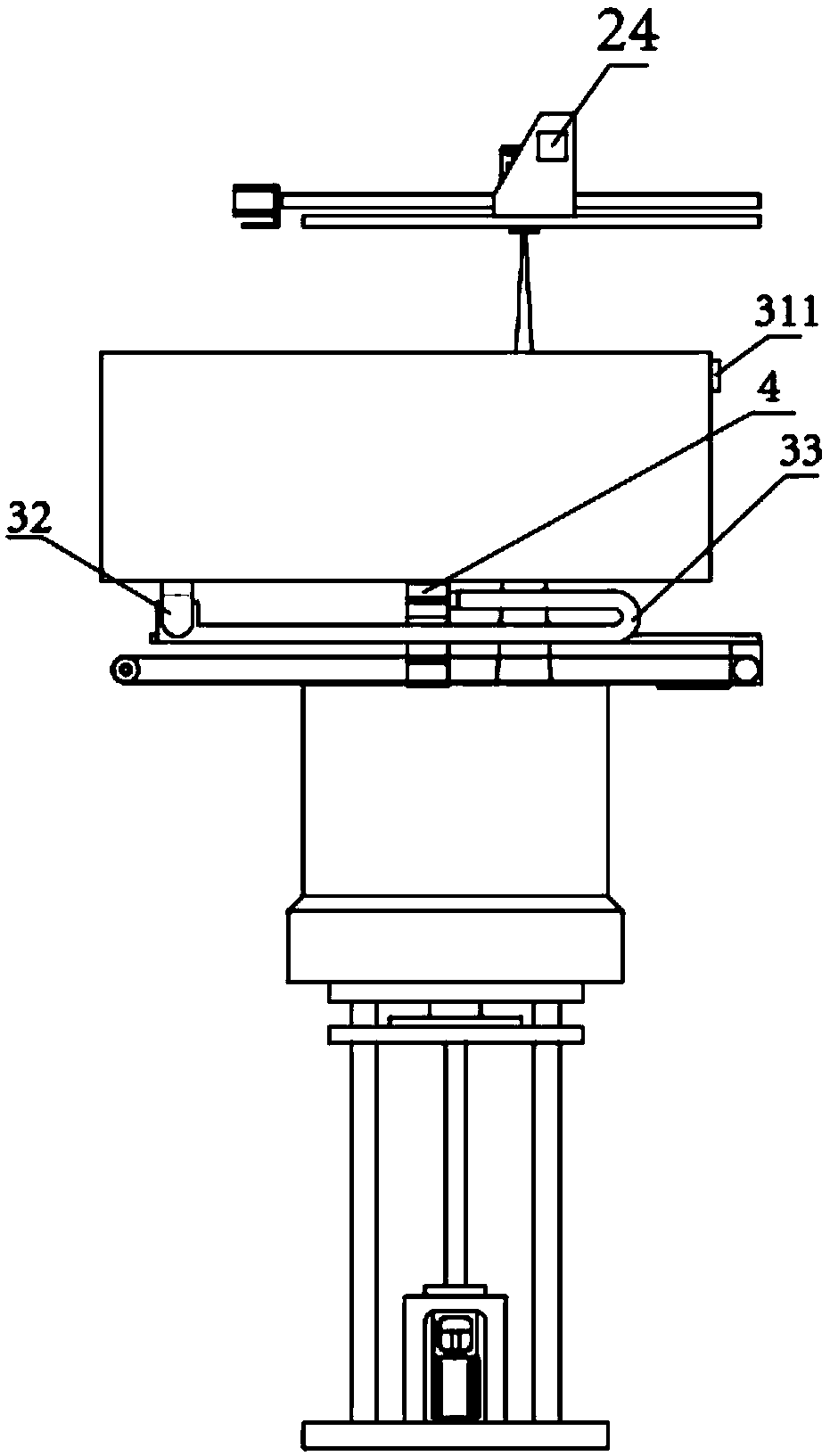

[0063] An unsupported 3D printing method: the photosensitive resin used for printing is a non-fluid paste at normal temperature, and when heated to 35-120°C, it melts into a fluid liquid state; including the following steps:

[0064] S1: Turn on the heating device outside the storage tank 31, preheat the photosensitive resin in the storage tank 31, and keep the temperature of the photosensitive resin in the storage tank 31 between 35-120°C;

[0065] S2: Form a three-dimensional model of the object to be printed, and divide the built three-dimensional model into n layers, each layer has the same height, which is regarded as a unit height, and transmit the cross-sectional information to the projection device;

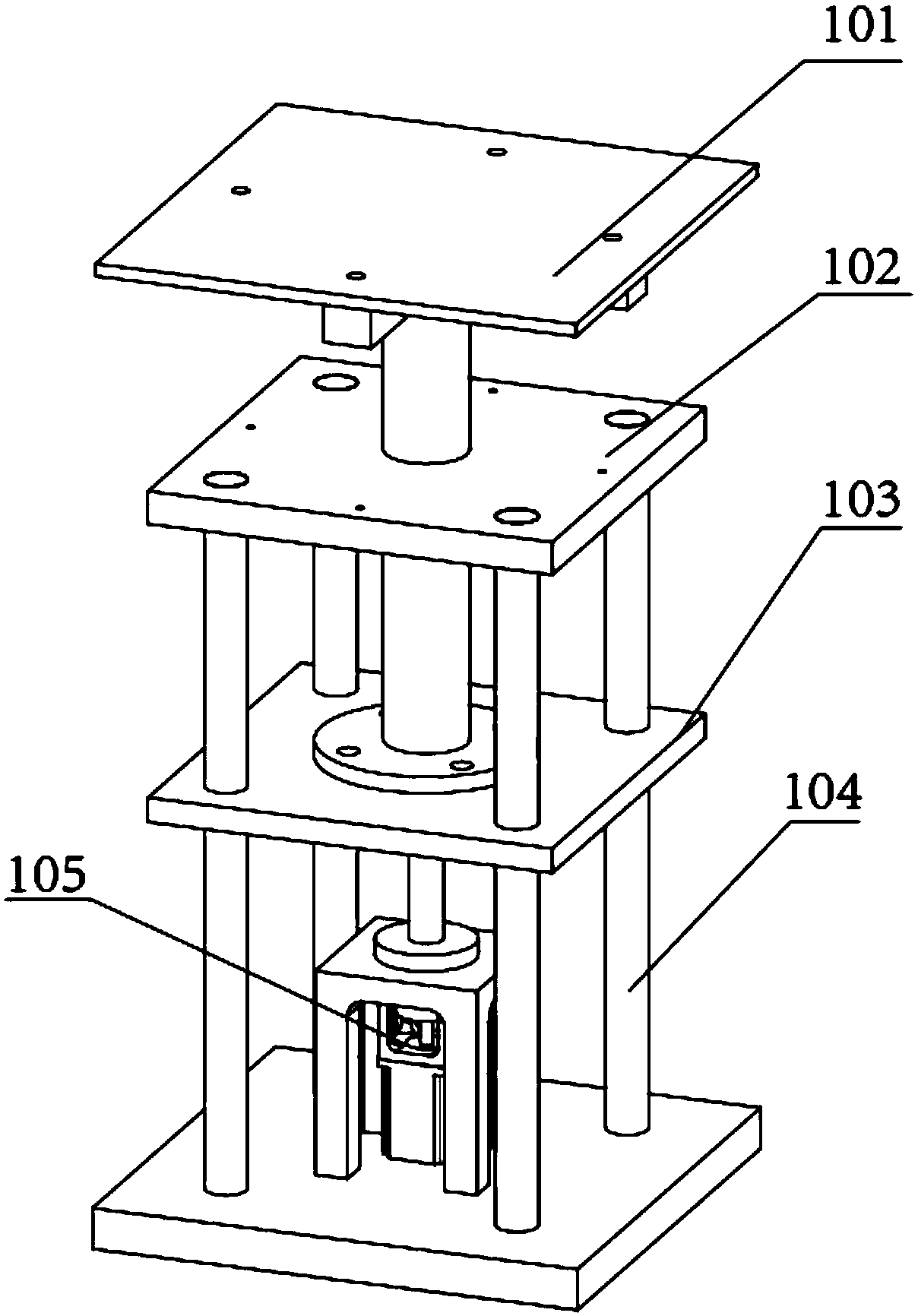

[0066] S3: The driving device of the printing platform 6 drives the printing platform 6 in the trough 8 to descend to a unit height, and the driving device of the scraper 4 drives the scraper 4 to perform a reciprocating motion to spread the liquid photosensitive resin in ...

Embodiment 2

[0073] An unsupported 3D printing method: characterized in that the photosensitive resin is a fluid liquid at normal temperature, and solidifies into a non-fluid paste when the temperature is lowered to 0 to -70°C; comprising the following steps:

[0074] S1: Form a three-dimensional model of the object to be printed, and divide the built three-dimensional model into n layers, each layer has the same height, which is regarded as a unit height, and transmit the cross-sectional information to the projection device;

[0075] S2: The driving device of the printing platform 6 drives the printing platform 6 in the trough 8 to drop to a unit height, and the driving device of the scraper 4 drives the scraper 4 to reciprocate, and evenly spreads the liquid photosensitive resin in the storage tank 31 on the printing platform 6 The thickness of the smear is the unit height; at the same time, the temperature control device outside the trough 8 is activated to cool the trough 8, and the liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com