Installation support and railway vehicle

A technology for installing brackets and slideways, which is used in railway vehicle lighting devices, transportation and packaging, and railway vehicle body parts, etc., and can solve problems such as mutual interference, many connection codes, and occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

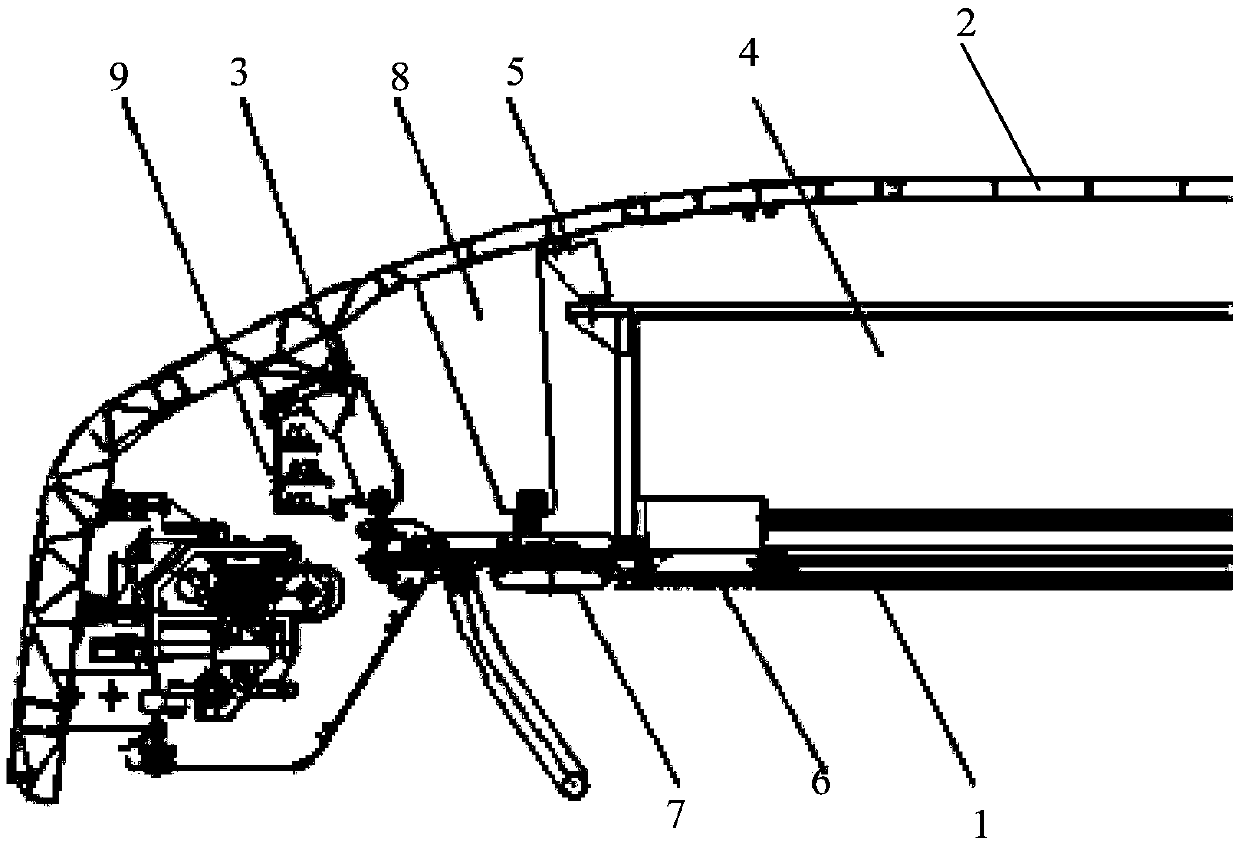

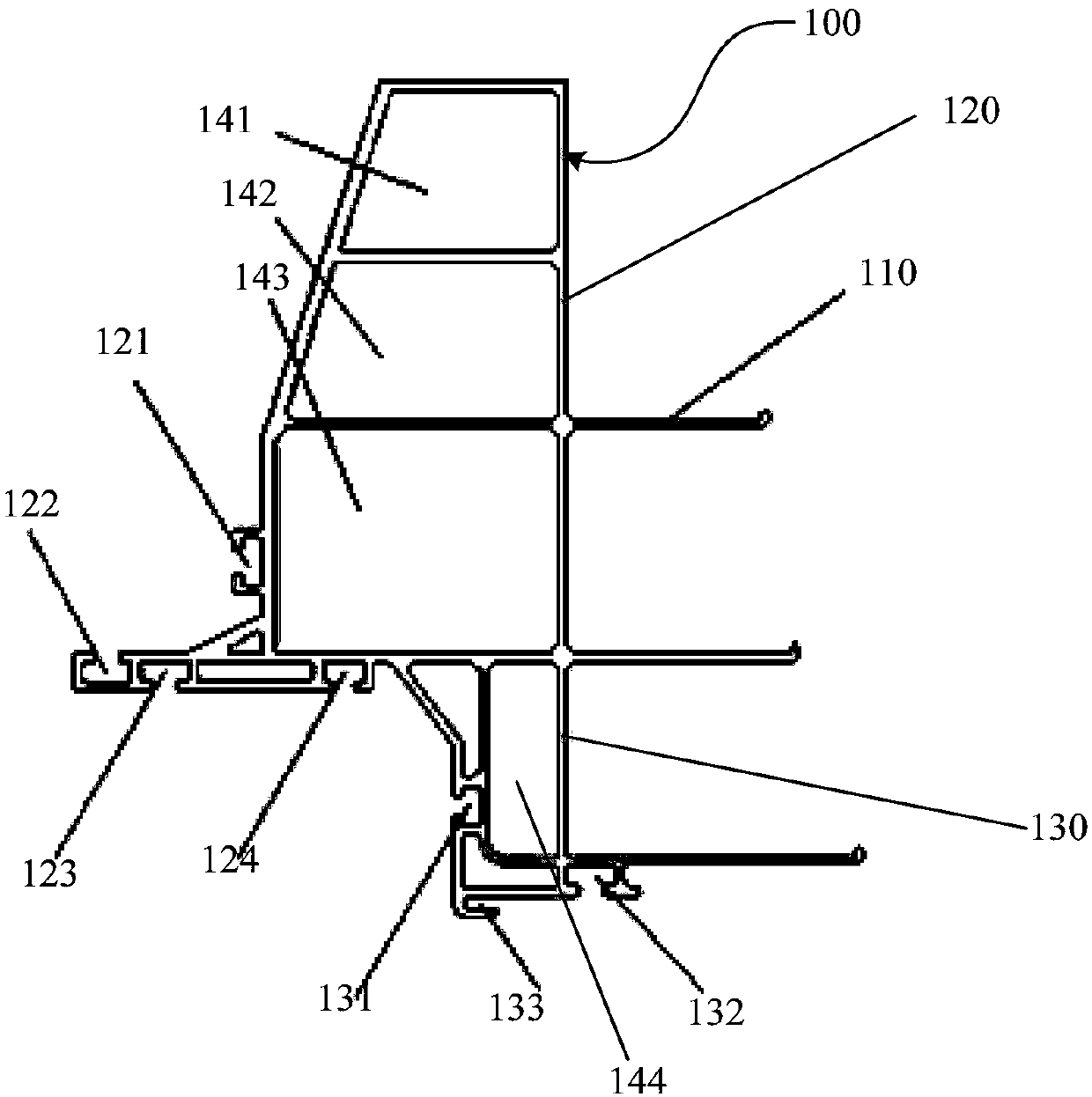

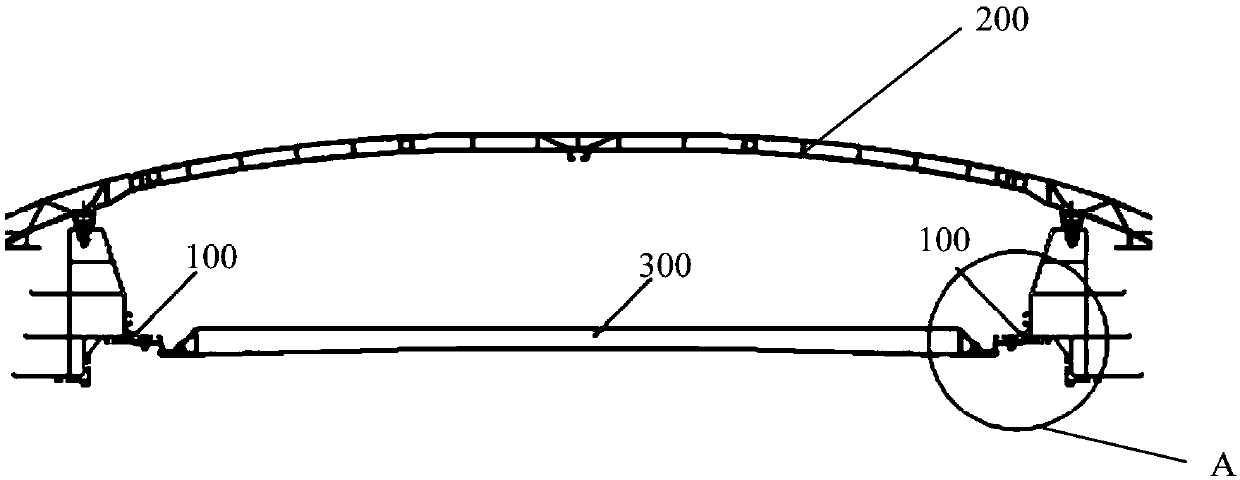

[0061] figure 2 A schematic diagram of the structure of the mounting bracket provided for an embodiment of the present invention; please refer to figure 2 . This embodiment provides a mounting bracket, including a bracket body 100 arranged along the length direction of the compartment, the top of the bracket body 100 is used to connect with the compartment roof 200, and the bracket body 100 is provided with a plurality of mounting brackets on the first side in the width direction of the compartment. For the support plate 110 on which the cable is installed, adjacent support plates 110 are spaced at a certain distance in the height direction of the compartment, and the bracket body 100 is provided with a plurality of connecting parts on the second side and the bottom surface in the width direction of the compartment, and the plurality of connecting parts They are respectively used to connect the middle top board 300, the lighting lamp 400, the side top board 500 and the hand...

Embodiment 2

[0079] The present embodiment provides a kind of rail train, comprises compartment, and compartment comprises compartment top plate, is also provided with middle top plate, illuminating lamp, side roof plate and handrail in compartment, passes between compartment top plate and middle roof plate, illuminator, side roof plate and handrail as above The mounting bracket described in Embodiment 1 is fixedly connected.

[0080] In the rail train provided in this embodiment, a plurality of support plates for installing cables are provided on the first side in the width direction of the carriage body of the support body, and adjacent support plates are separated by a certain distance in the height direction of the carriage. The second side and the bottom surface in the width direction of the body compartment are provided with a plurality of connecting parts, which are respectively used to connect the middle roof, the lighting, the side roof and the handrail, so that the cables, the mid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com