A kind of method and application of preventing high temperature oxidation during hot working of magnesium fluoride

A high-temperature oxidation and thermal processing technology, applied in the direction of magnesium fluoride, magnesium halide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

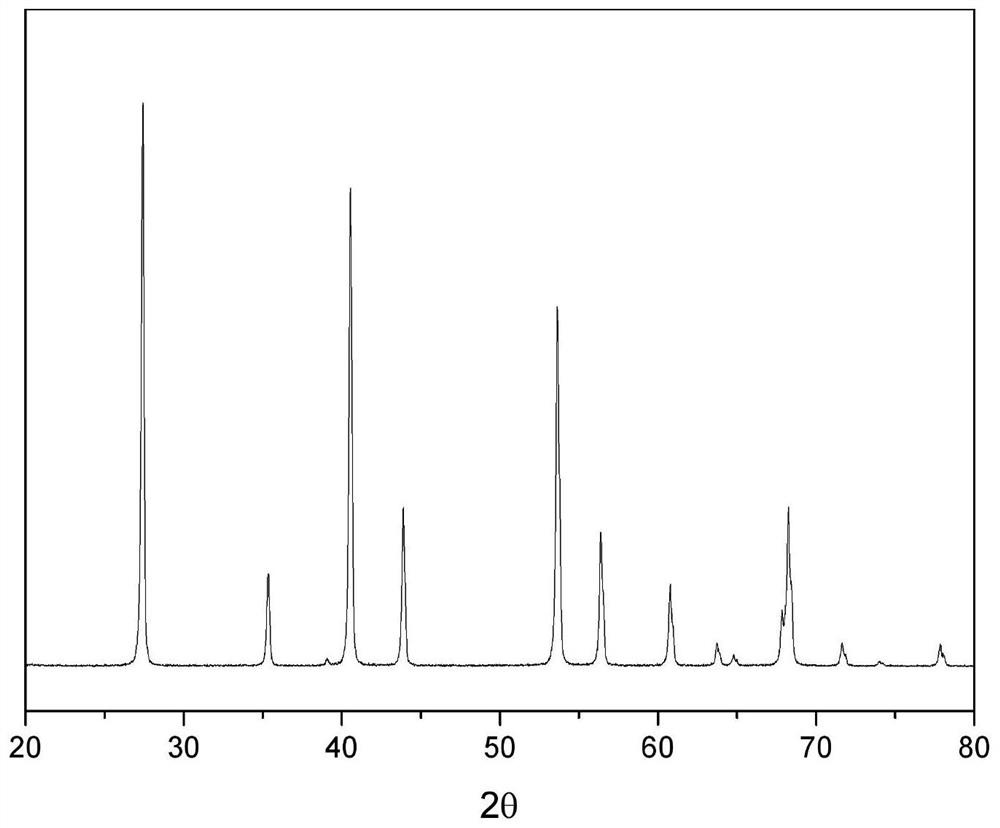

[0030] In a tube furnace equipped with a gas supply system, put 10g of powdered MgF with a purity of 99.9% 2 corundum crucible, and then into the SF 6 / air mixed gas, the mixed gas flow rate is 300mL / min, of which SF 6 Accounting for 1% of the volume of the mixed gas, the temperature of the tube furnace was gradually raised to 1000 ° C, and the temperature was kept for 2 hours, and then the MgF 2 cooled to room temperature, the powdered MgF 2 Carry out XRD pattern analysis, do not detect the existence of MgO (see figure 1 ).

Embodiment 2

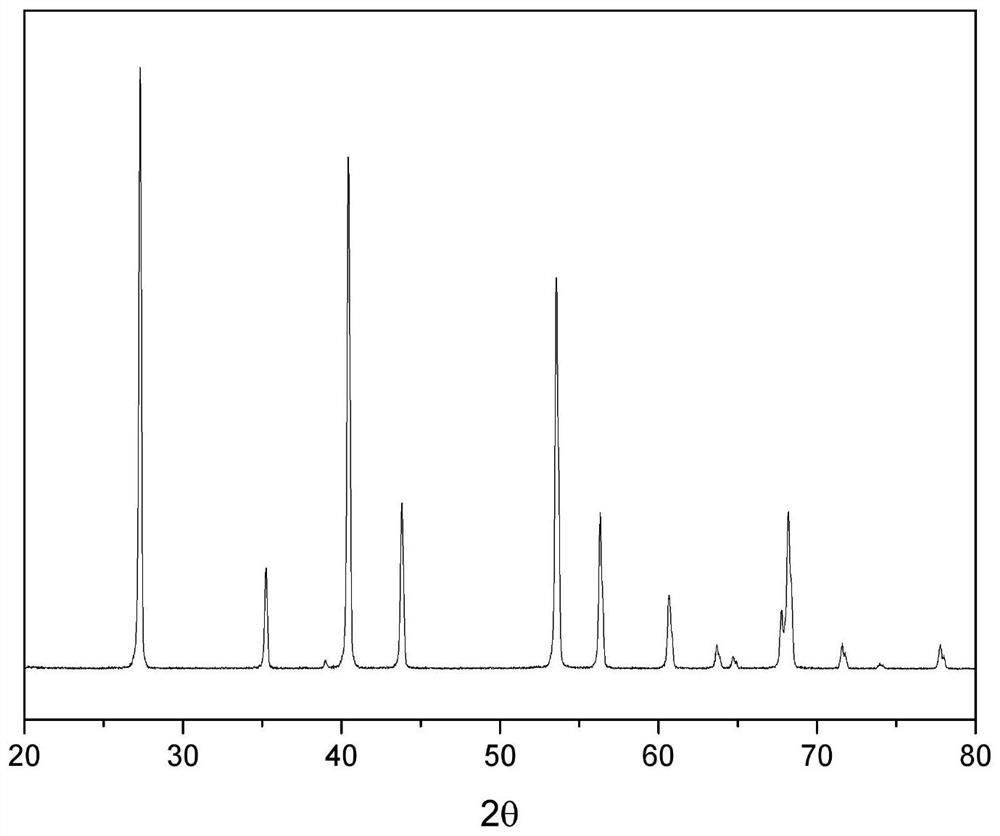

[0032] In a tube furnace equipped with a gas supply system, put 10g of powdered MgF with a purity of 99.9% 2 corundum crucible, and then into tetrafluoroethane (molecular formula CF 3 CH 2 F) / air mixed gas, the mixed gas flow rate is 300mL / min, wherein tetrafluoroethane accounts for 1% of the mixed gas volume, the tube furnace is gradually heated to 1000 ° C, kept for 2 hours, and then the MgF 2 cooled to room temperature, the powdered MgF 2 Carry out XRD pattern analysis, do not detect the existence of MgO (see figure 2 ).

Embodiment 3

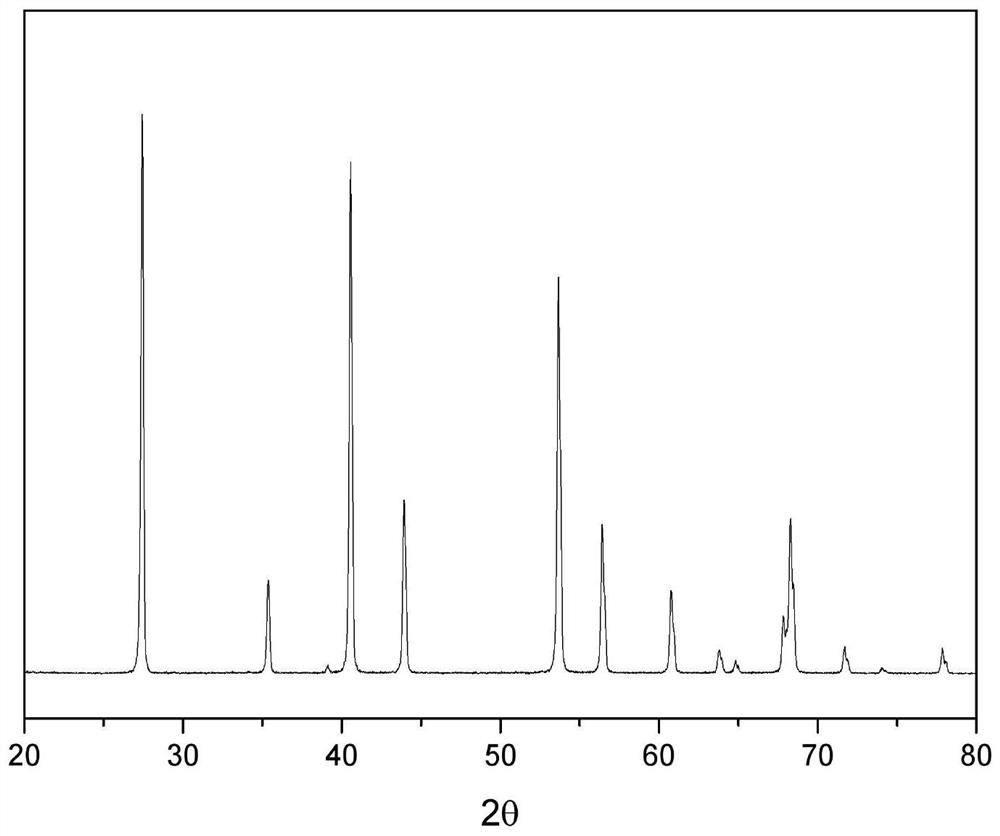

[0034] In a tube furnace equipped with a gas supply system, put 10g of powdered MgF with a purity of 99.9% 2 corundum crucible, and then into hexafluoropropylene (molecular formula C 3 f 6 ) / air mixed gas, the mixed gas flow rate is 300mL / min, in which hexafluoropropylene accounts for 1% of the mixed gas volume, the tube furnace is gradually heated to 1000 ° C, kept for 2 hours, and then the MgF 2 cooled to room temperature, the powdered MgF 2 Carry out XRD pattern analysis, do not detect the existence of MgO (see image 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com