New method for preparing N-n-butyl acrylamide

A technology of n-butylacrylamide and methylthiopropionamide, which is applied in the preparation of carboxylic acid amides, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of strong burns, flammability, and volatility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

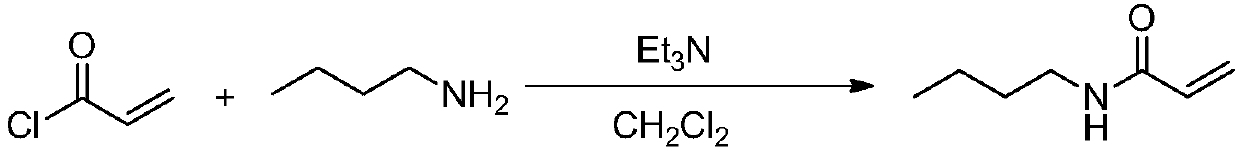

Method used

Image

Examples

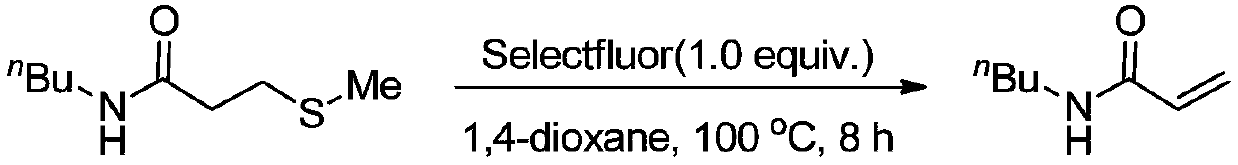

specific Embodiment 1

[0013] In a 100mL round bottom flask, N-butyl-3-methylthiopropionamide (20mmol, 3.51g), 1-chloromethyl-4-fluoro-1,4-diazabicyclo[2.2.2 ] Octane bis(tetrafluoroborate) salt (20mmol, 3.55g) and 20mL of 1,4-dioxane, the reaction temperature was controlled at 100°C, and the reaction was vigorously stirred for 8h. After the reaction, cool to room temperature, wash the reaction system with water, extract, distill the filtrate under reduced pressure, and collect the main fraction to obtain N-n-butylacrylamide (2.42 g, 95%).

[0014] The equations involved in the reaction are as follows:

[0015]

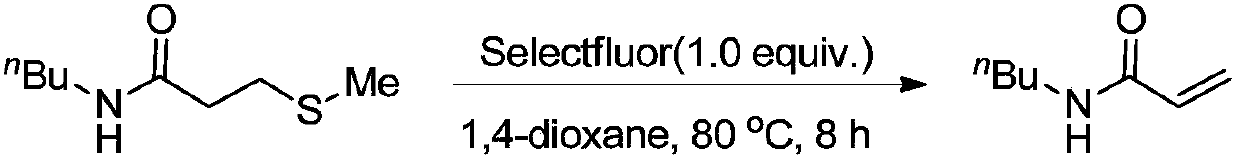

specific Embodiment 2

[0016] In a 100mL round bottom flask, N-butyl-3-methylthiopropionamide (20mmol, 3.51g), 1-chloromethyl-4-fluoro-1,4-diazabicyclo[2.2.2 ] Octane bis(tetrafluoroborate) salt (20mmol, 7.10g) and 20mL of N,N-dimethylformamide, the reaction temperature was controlled at 80°C, and the reaction was vigorously stirred for 8h. After the reaction, cool to room temperature, wash the reaction system with water, extract, distill the filtrate under reduced pressure, and collect the main fraction to obtain N-n-butylacrylamide (2.29 g, 90%).

[0017]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com