A Method for Evaluation of Coke Deterioration Degree in Blast Furnace

An evaluation method, coke technology, applied in blast furnaces, blast furnace details, chemical process analysis/design, etc., can solve problems such as difficulty, iron slag weight ratio has a great influence, cannot accurately reflect the degree of coke deterioration, etc., and reduce labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Example 1 (at 3200m 3 The test was carried out by taking samples 1m away from the tuyere in a blast furnace)

[0035] A method for evaluating the degree of deterioration of coke in a blast furnace, the steps of which are:

[0036] 1) Analyze the particle size of the coke entering the furnace the day before the blast furnace shutdown, and take the average particle size as the average particle size M of the coke entering the furnace 1 ; See Table 1 for details

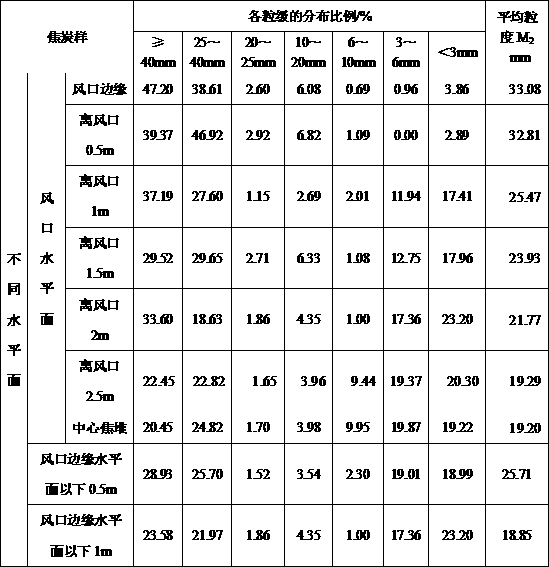

[0037] Table 1 The particle size distribution of coke before entering the furnace in this embodiment

[0038]

[0039] Take the average coke particle size average of the above three times as the average particle size M of coke entering the furnace 1 =50.18mm;

[0040] 2) When the blast furnace is repaired, the coke samples in the blast furnace are taken to analyze the average particle size and particle size distribution of the coke;

[0041] 3) First remove the gun mud and slag in the coke taken, and then ...

Embodiment 2

[0062] Example 2 (at 4000m 3 The test was carried out by taking samples 1.5m away from the tuyere in a blast furnace)

[0063] A method for evaluating the degree of deterioration of coke in a blast furnace, the steps of which are:

[0064] 1) Analyze the particle size of the coke entering the furnace the day before the blast furnace shutdown, and take the average particle size as the average particle size M of the coke entering the furnace 1 ; See Table 3 for details

[0065] Table 3 The particle size distribution of coke before entering the furnace in this embodiment

[0066]

[0067] Take the average coke particle size average of the above three times as the average particle size M of coke entering the furnace 1 =50.04mm;

[0068] 2) When the blast furnace is repaired, the coke samples in the blast furnace are taken to analyze the average particle size and particle size distribution of the coke;

[0069] 3) First remove the gun mud and slag in the coke taken, and the...

Embodiment 3(3200

[0090] Example 3 (3200m 3 level blast furnace)

[0091] 1) Sampling and analyzing the coke entering the furnace one day before repairing in the blast furnace to calculate the average particle size, taking the average value as the average particle size of the coke entering the furnace, denoted as M 1 =50.12

[0092] Table 5 The particle size distribution of coke before entering the furnace in this embodiment

[0093]

[0094] Take the average coke particle size average of the above three times as the average particle size M of coke entering the furnace 1 =50.12mm;

[0095] 2) During the intermediate maintenance of the blast furnace, when the material level in the furnace is lowered to a certain position, the furnace will be shut down and the hearth will be manually dug; during the process of hearth digging, coke will be collected from different levels in the entire furnace and different positions on the same level Sample, according to the method of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com