Prefabricated underground diaphragm wall and construction method thereof

An underground continuous wall and wall technology, which is applied to sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of inconvenient hoisting, easy flow around concrete pouring, etc. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

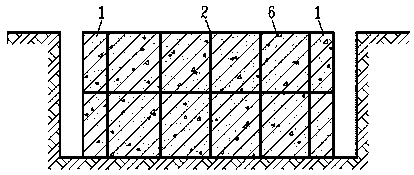

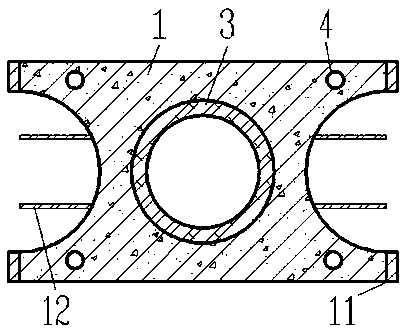

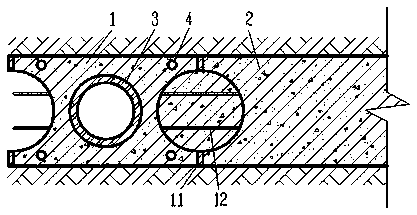

[0048] Example: such as Figure 1-Figure 6As shown, the prefabricated underground diaphragm wall and its construction method include a prefabricated joint 1 and a prefabricated continuous wall 2; the cross-section of the prefabricated joint 1 is I-shaped, and the concave surfaces on the left and right sides are semi-arc-shaped, and are made of reinforced concrete. There is an impact-resistant pipe 3, and the upper and lower surfaces are provided with reserved bolt holes 4 for joints, and the adjacent joints are mechanically connected by expansion bolts 13; the prefabricated continuous wall 2 is composed of a plurality of prefabricated continuous wall sections 6, and the cross section is rectangular. There are bolt holes 7 reserved on the upper and lower surfaces of the wall, and the adjacent walls are mechanically connected by expansion bolts 13. There are protrusions 8 and grooves 9 on the left and right, and water-stop rubber pads 11 are provided on the surface of the groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com