Compact single-action hydraulic booster

A hydraulic booster, single-acting technology, applied in fluid pressure converters, fluid pressure actuators, mechanical equipment, etc., can solve problems such as adverse effects on service life, complex structure, and difficult processing, and achieve no impact vibration , high integration and compact size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

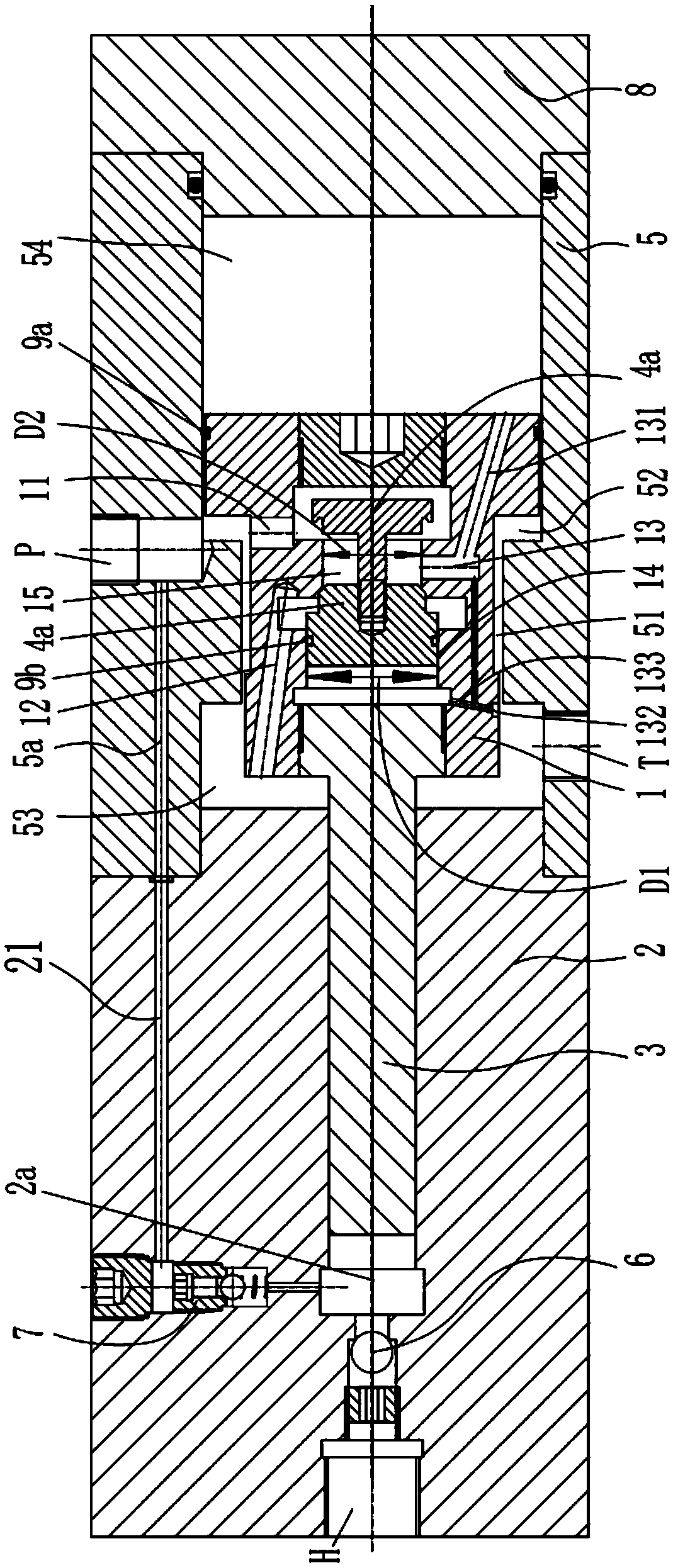

[0014] Such as figure 1 Shown is a preferred embodiment of the present invention.

[0015] A compact single-acting hydraulic booster comprising

[0016] A valve casing 5 with an axial hole, an oil inlet P and an oil return port T connected to the axial hole are opened on the side wall of the valve casing 5, and the middle part of the inner hole wall of the valve casing 2 has a first annular inner shoulder blade 51. The oil port P and the oil return port T are located on the left and right sides of the first annular inner shoulder blade 51;

[0017] The left cylinder body 2 and the right cylinder body 8 with the plunger chamber 2a are respectively connected to the left and right ends of the axial channel of the valve casing 5, and the left cylinder body 2 is provided with a left oil inlet flow channel 21 and a high-pressure oil port H. The o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com