Novel thin oil lubrication flange type vibration exciter

A thin-oil lubricated, flange-type technology, which is applied in the field of thin-oil-lubricated flange-type vibrators, can solve the problems that the service life affects the normal operation of vibration equipment, affects the service life of the vibrator, and the bearing temperature of the bearing is locked. It achieves the effect of convenient and simple maintenance, compact structure and prolonged service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

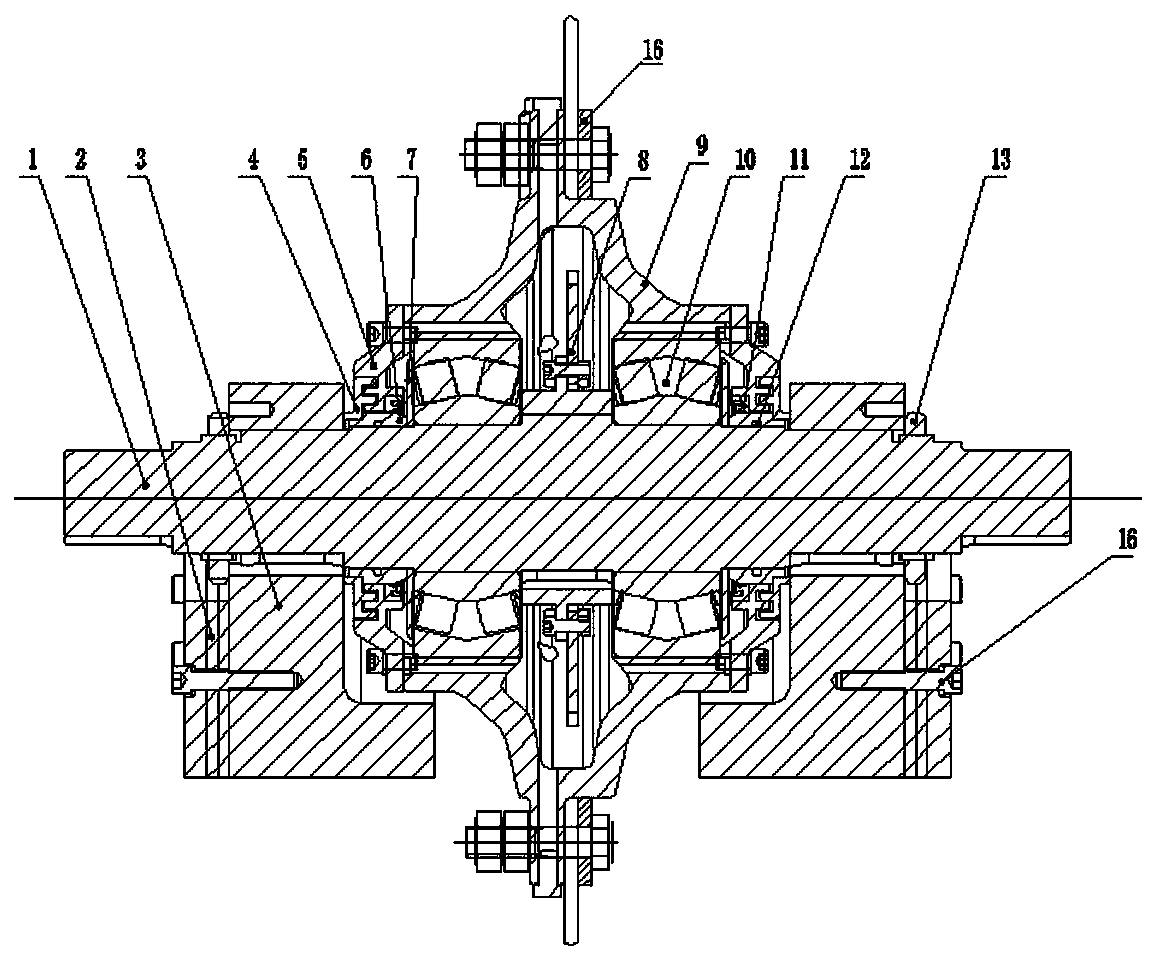

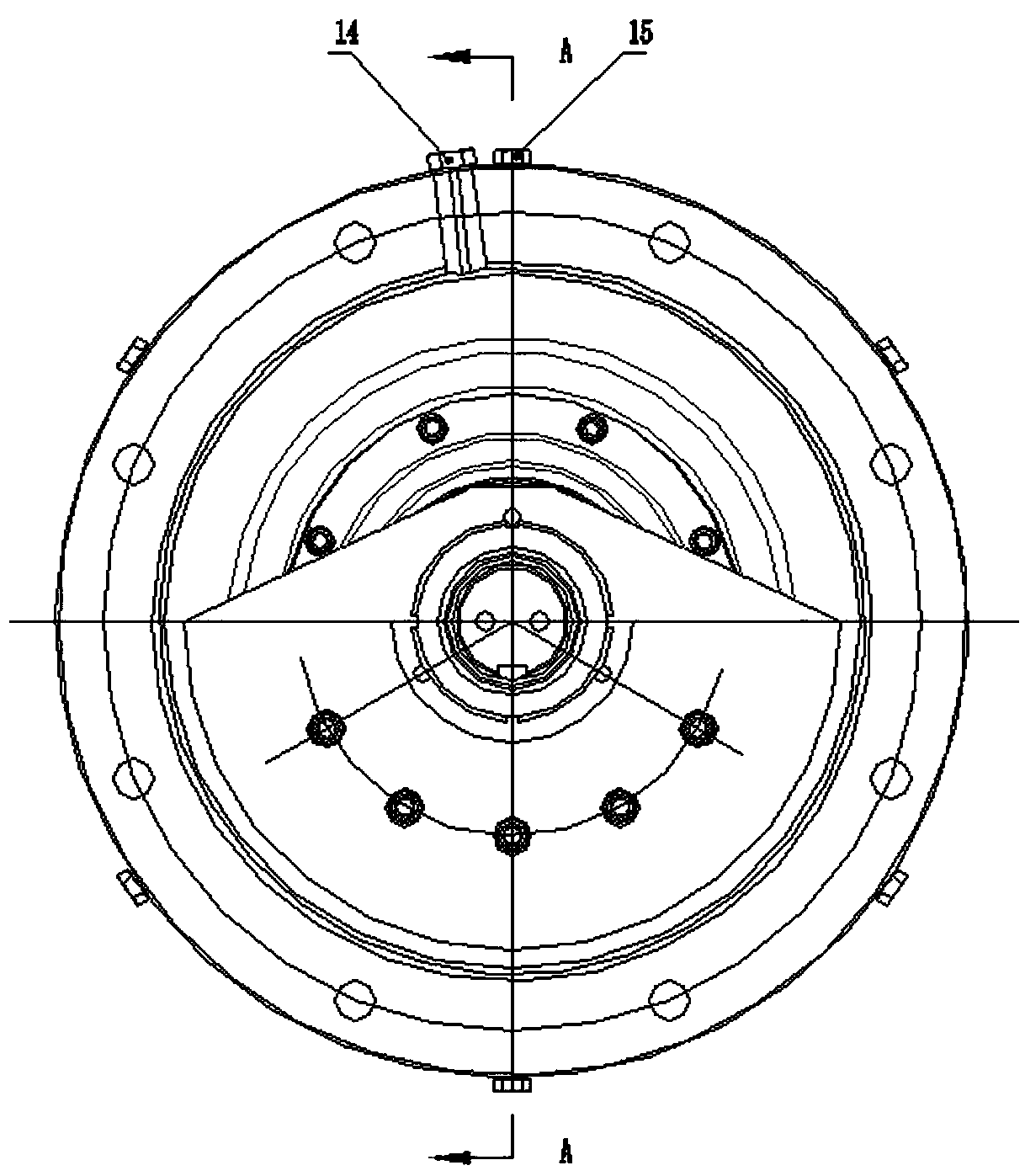

[0016] Example: see figure 1 and figure 2 , a thin oil lubricated flange type vibrator, including shaft 1, counterweight 2, eccentric block 3, labyrinth cover 4, through hole cover 5, shaft sleeve 6, oil throwing ring 7, oil stirring gear 8, bearing Chamber 9, bearing 10, oil seal 11, O-shaped rubber ring 12, round nut 13, breathable cap 14, oil injection hole 15 and flange 16, the counterweight 2 is fixed on the eccentric block 3 by bolts to adjust the excitation force of the exciter Shaft 1 runs through eccentric block 3, labyrinth cover 4, through hole cover 5, shaft sleeve 6, oil throwing ring 7, oil stirring tooth 8, bearing chamber 9, bearing 10, oil seal 11, O-shaped rubber ring 2, circle The center hole of each part of the nut 13 forms a closed lubricating oil storage room between the two bearings 10, wherein: there are two bearings 10, the shaft heads at both ends of the shaft 1 match the coupling, and the bearing room 9 passes through the flange 16 is screwed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com