Central heating system for segmented cooling of multipath backwater of circulating cooling water

A technology of cooling circulating water and segmented cooling, applied in hot water central heating system, heating system, household heating and other directions, can solve the problems of high consumption and difficult for heat users to ensure the temperature parameters of the process medium, and achieve energy saving, Solve the effect of equipment location and pipeline routing, reducing resource consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

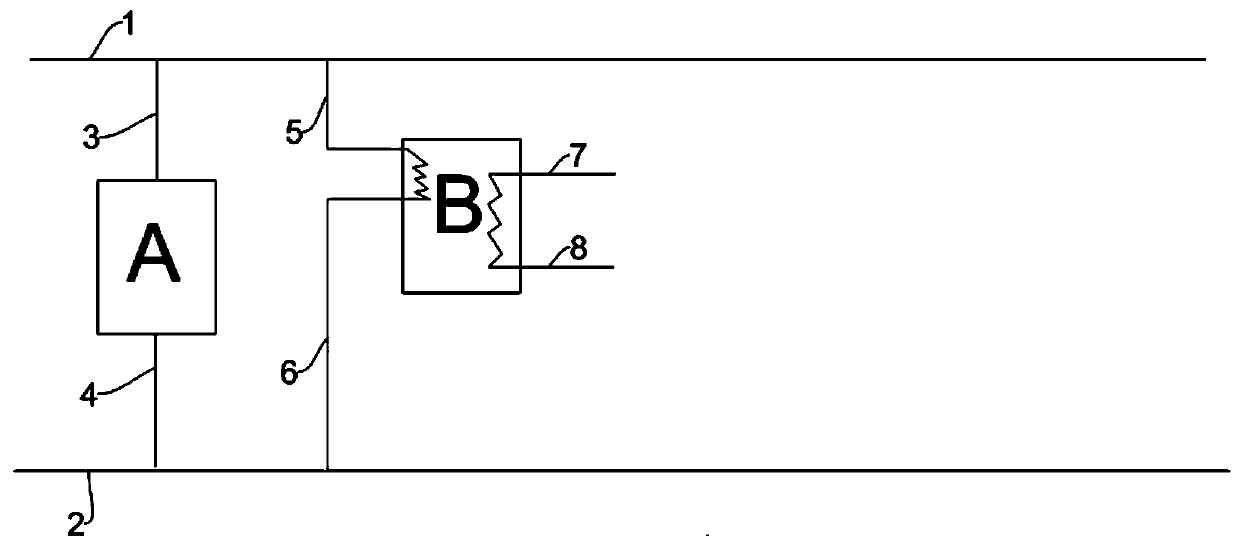

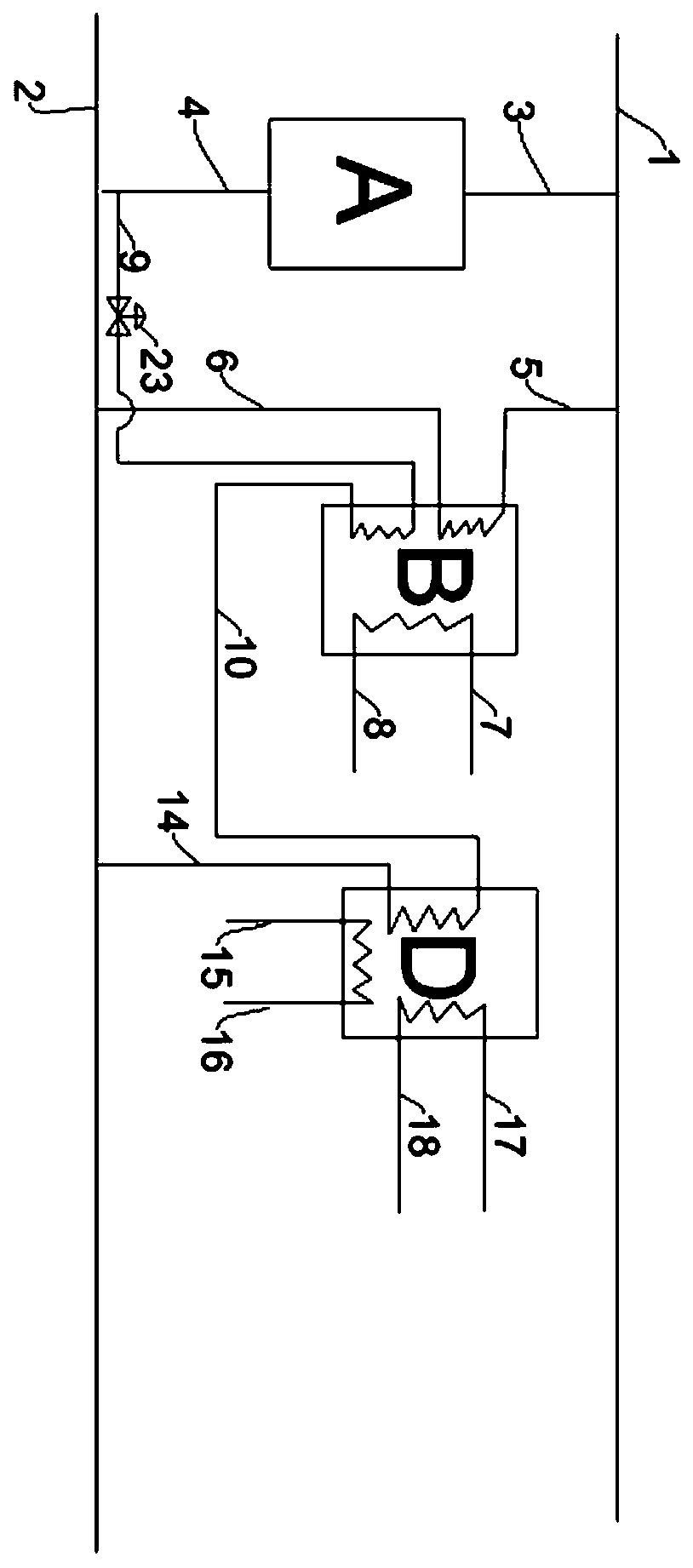

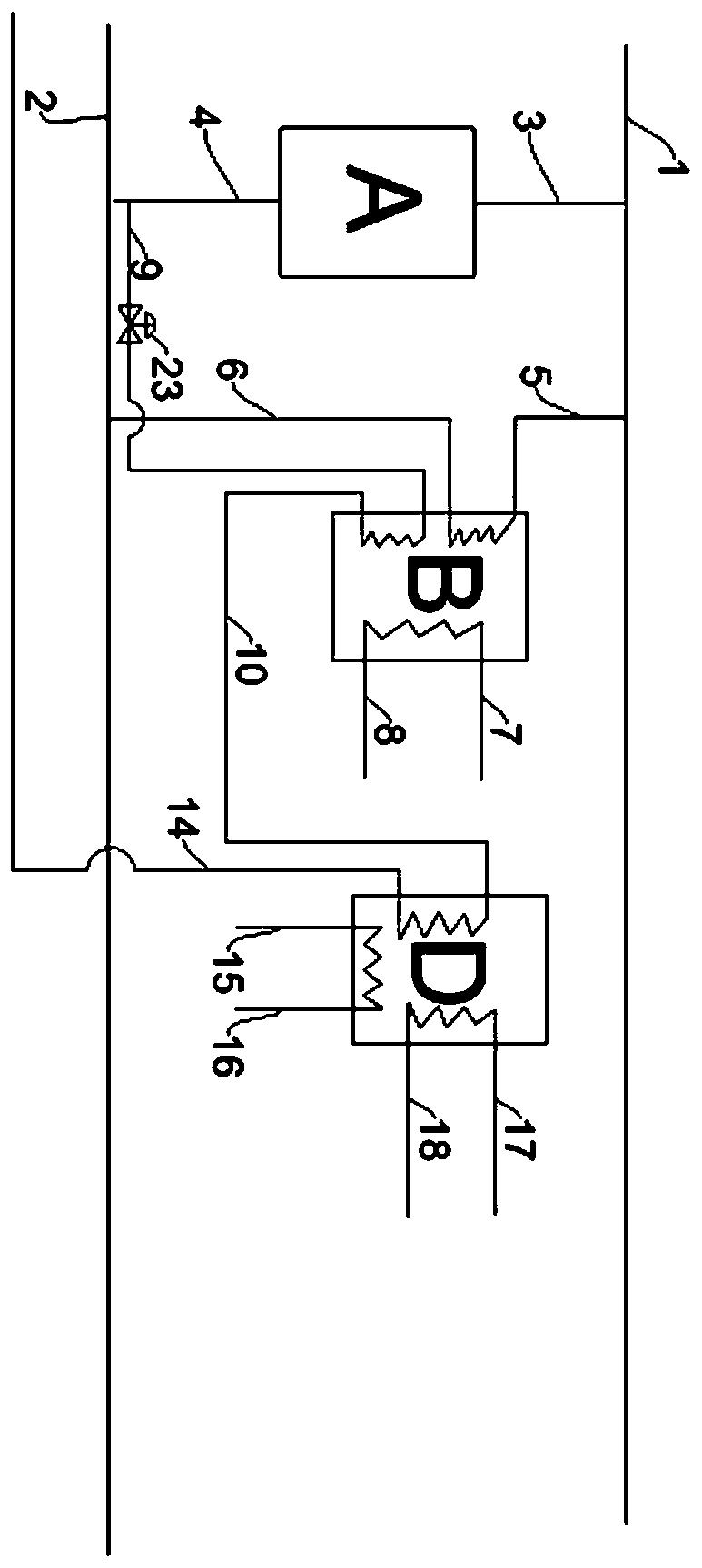

[0043] A centralized heating system with multi-return water segmental cooling of cooling circulating water, as shown in Figure 2(a), includes a cooling circulating water supply line 1 connected to a heat exchange device through a cooling circulating water supply line 3 of a heat exchanger A A, the cooling circulating water return line 2 is connected to the heat exchange device A through the cooling circulating water return line 4 of the heat exchanger A, and the cooling circulating water return line 4 of the heat exchanger A passes through the pipeline 9 to control the valve 23, heat exchange The high-temperature cooling circulating water supply pipeline 9 of the device B is connected to the heat exchange device B, and the heat exchange device B is connected to the waste heat energy deployment center D through the high-temperature cooling cycle water return line 10 of the heat exchanger B, and the waste heat energy deployment center D is through the deployment The high-temperat...

Embodiment 2

[0059] According to the method shown in embodiment 1, such as image 3 , characterized in that the waste heat energy allocation center D is connected to the water quality temperature monitoring and control equipment E through the high temperature cooling circulating water return pipeline 14 of the allocation center D, and the water quality temperature monitoring and control equipment E controls the valve 24 and the controller E through the pipeline 25 in turn. The cooling circulating water return line 25 is connected to the circulating water return line 2 , and the water quality temperature monitoring and control equipment E is connected to the heat exchange device B through the cooling circulating water closed circulation line 26 .

[0060] The cooling circulating water in the high-temperature cooling circulating water return line 14 of the deployment center D passes through the water quality temperature monitoring and control equipment E, and enters the heat exchange device B...

Embodiment 3

[0064] According to the method described in embodiment 1, it is characterized in that, as Figure 4 As shown, the heat exchange device B is connected to the reheater C through the high-temperature cooling circulating water return pipeline 10 of the heat exchanger B, and the reheater C is connected to the waste heat energy distribution center through the high-temperature cooling circulating water inlet pipeline 13 of the distribution center D d.

[0065] The reheater C is connected to the higher temperature process medium inlet pipeline 11 and the higher temperature process medium return pipeline 12 .

[0066] The high-temperature cooling circulating water in the high-temperature cooling circulating water return line 10 of the heat exchanger B enters the reheater C from the high-temperature cooling circulating water return line 10 of the heat exchanger B and continues to serve as a cooling cold source after heat exchange and heating The high-temperature cooling circulating wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com