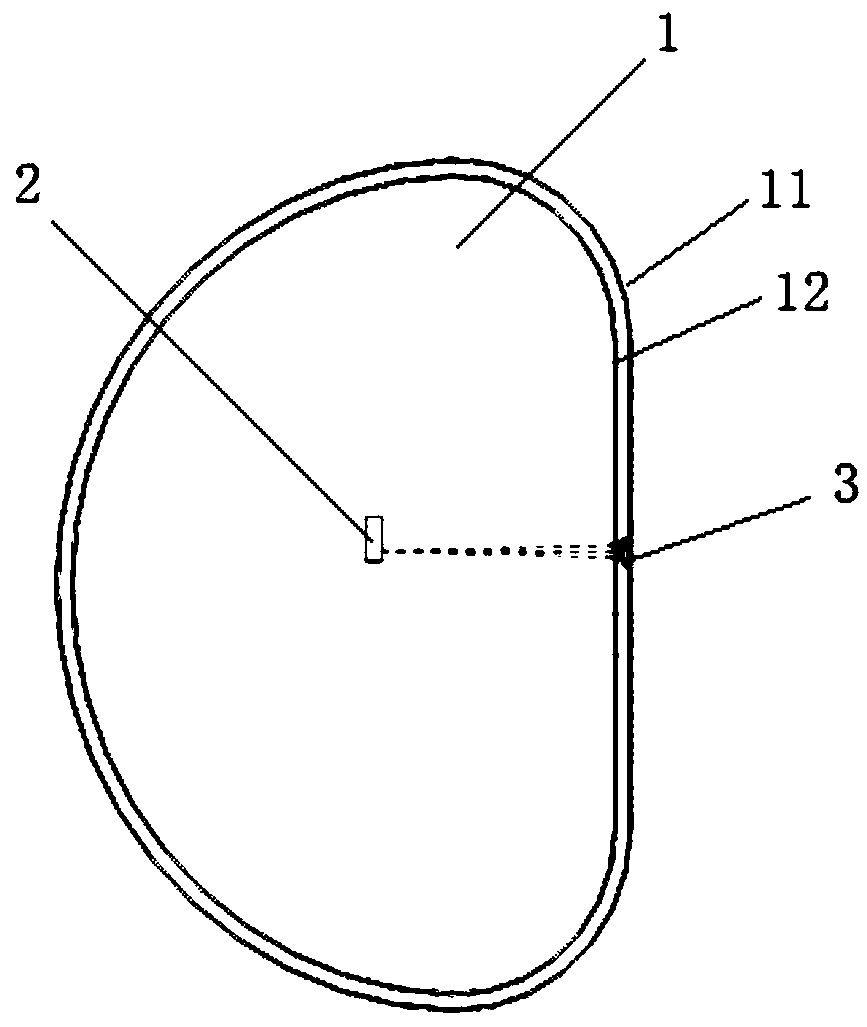

CFETR (Chinese fusion engineering testing reactor) vacuum chamber pre-grinding piece longitudinal weld joint automatic flaw detection positioning device

A technology of longitudinal welding seam and positioning device, which is used in measuring devices, instruments, scientific instruments, etc., can solve the problems of narrow space on the back of the welding seam, exposure of operators to the ray environment, restricting the application of conventional cloth devices, etc., and achieves a degree of automation. High, improve the effect of detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

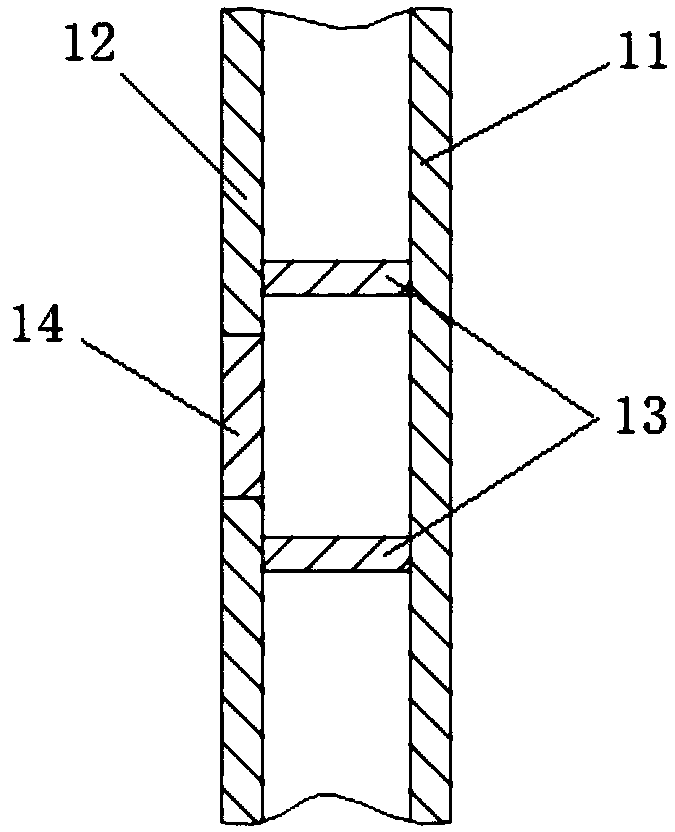

[0028] As an optimization description of the above technical solutions:

[0029] The rollers 31 at the four corners of the bottom of the flaw detection vehicle 3 include two driving wheels on one side of the bottom of the flaw detection vehicle 3 and two driven wheels on the other side of the bottom of the flaw detection vehicle 3. force and steering force. The purpose is that the cooperation between the driving mechanism and the wheel body of the flaw detection vehicle 3 can not only easily realize the driving and steering, but also has the advantage of high synchronization of the four rollers there.

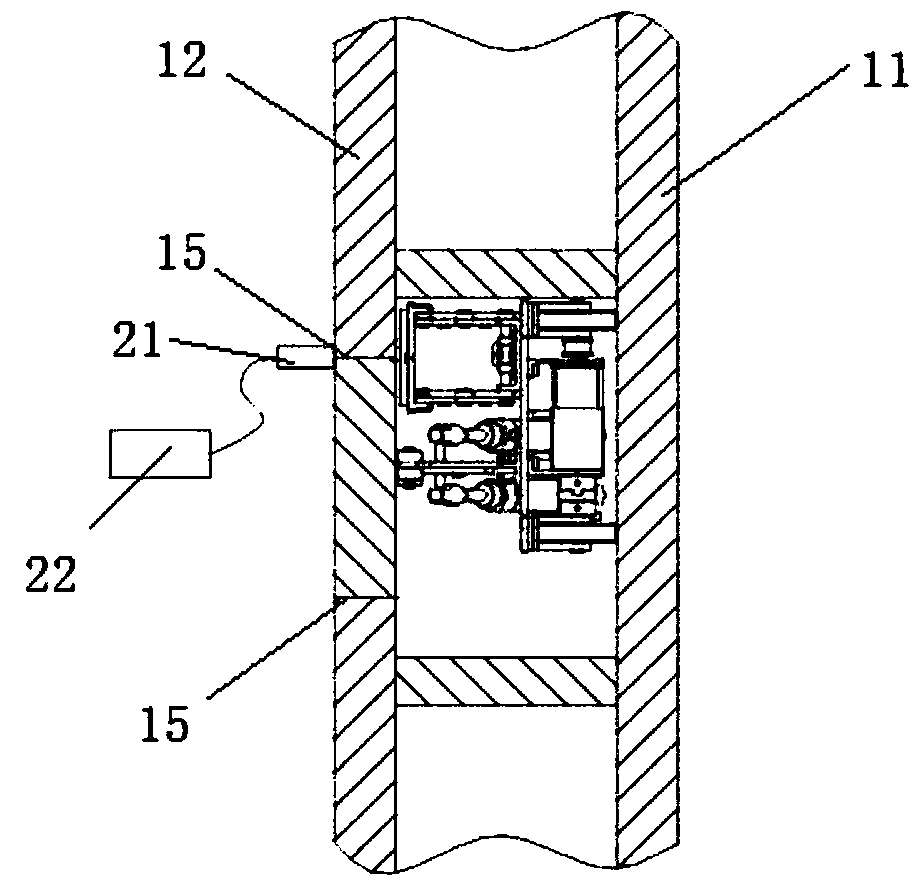

Embodiment 2

[0031] As an optimization description of the above technical solutions:

[0032] Such as Figure 6As shown, the telescopic frame 331 of the cloth mechanism 33 includes four groups of X-shaped brackets, and two groups of X-shaped brackets are correspondingly arranged on two groups of X-shaped brackets of the other two groups, and the contact ends are hinged by pin shafts. The middle part is composed of hinged rods 3311, the bottom side of the two rods 3311 at the same end in the lower two groups of X-shaped brackets are all hinged on the fixing seat 3312, and the top side is slidingly installed on the side wall of the dark bag fixing plate 332 through pins. In the shaped hole, the bottom and other side of the other two rods 3311 at the same end of the lower two groups of X-shaped brackets are connected to the bar-shaped hole of the sliding seat 3313 of the cloth mechanism through the connecting shaft 3312, and the top side is fixed in the dark bag through a pin. On the side wa...

Embodiment 3

[0035] The sensor 21 is signal connected with an audible and visual alarm 22 . The purpose is to conveniently notify the operator that the flaw detection vehicle 3 has reached the set position and start to detect the longitudinal weld, so that the control is more timely and accurate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com