A passive online rehydration device and method for containment filtration and discharge system

A liquid replenishing device and passive technology, applied in the field of nuclear power plants, can solve the problems of plant integrity and tightness, additional reservation of plant structures, and complicated design of shielding walls, etc. Relevant auxiliary equipment, saving effect of personnel shielding wall design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

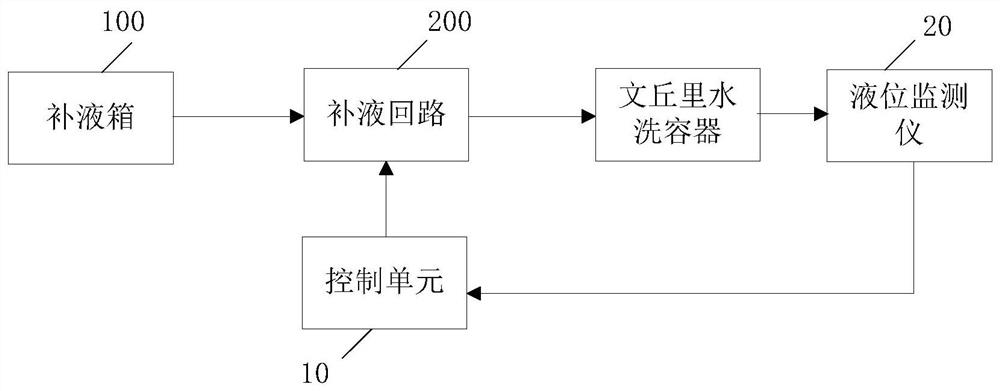

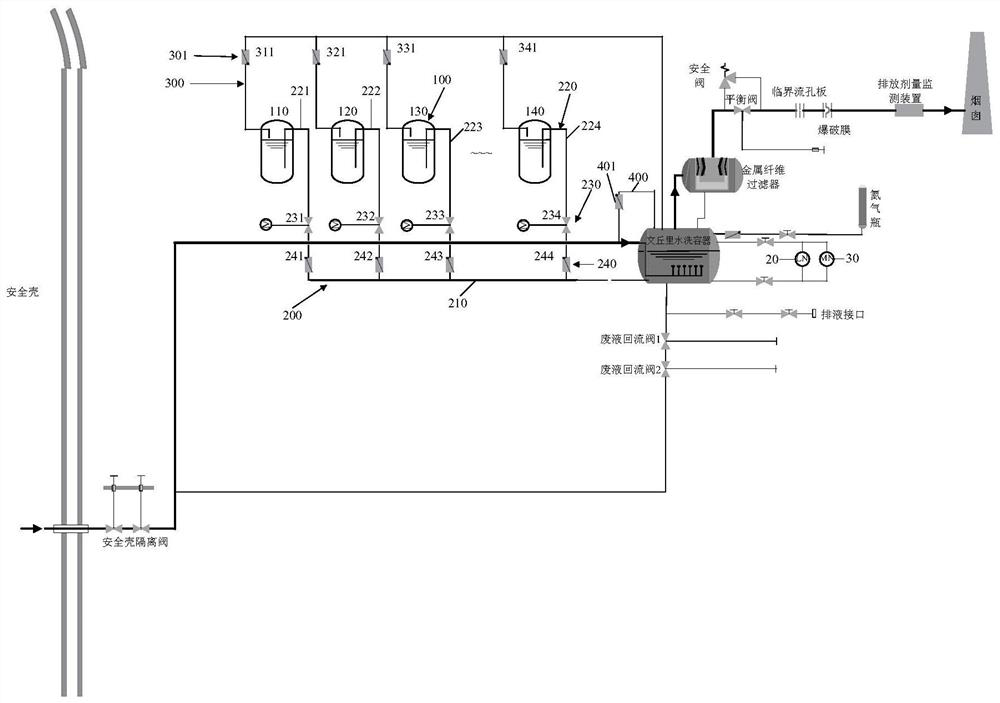

[0024] The implementation of the present invention provides a passive online rehydration device for the containment filtration and discharge system, which is used to controllably refill the Venturi water washing container of the containment filtration and discharge system when a serious accident is executed. Under severe accident conditions in nuclear power plants, the radioactive gas generated in the containment is filtered and discharged, which mainly discharges the radioactive substances in the gas directly through the washing solution in the Venturi washing container, and the retained radioactive nuclei in the washing solution in the Venturi washing container The ability of the element and the liquid level have a specific self-sustaining time and the minimum required liquid level height. When the liquid level is lower than the minimum liquid level requirement, it is necessary to replenish the Venturi washing container to maintain its effective filtering and washing function,...

Embodiment 2

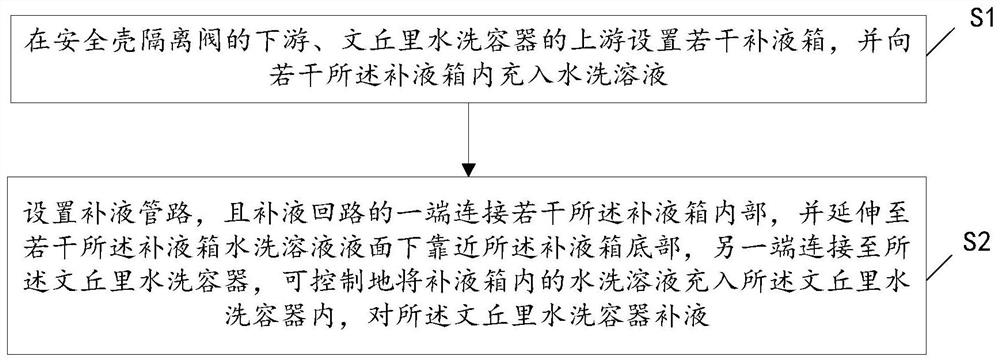

[0035] The embodiment of the present invention provides a passive online rehydration method for the containment filtration and drainage system, such as image 3 shown, including:

[0036] Step S1, setting up a number of rehydration tanks downstream of the containment isolation valve and upstream of the Venturi water washing container, and filling the number of rehydration tanks with washing solution; the material of the refill tanks 100 is a material with anti-corrosion capability, preferably, It can be stainless steel, which is used to prevent several rehydration tanks 100 from being ineffective due to being corroded by water washing solution; wherein, some rehydration tanks 100 are filled with configured sodium hydroxide (NaOH) and sodium thiosulfate (NaOH) 2 S 2 o 3 ) mixed solution, which is used to effectively retain radionuclides in the nuclear power plant containment filter exhaust gas; and when the online rehydration device is in standby, several rehydration tanks 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com