Sn-113/In-113m generator and preparation method

An in-113m, sn-113 technology, applied in the field of Sn-113/In-113m generator preparation, can solve the problems of large radiation dose, long operation time and low adsorption capacity of operators, and reduce the exposure Irradiation risk, effect of fast leaching rate and low leakage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A kind of preparation method of Sn-113 / In-113m generator, comprises the steps:

[0025] 1) In the container, put into pH=1, volume is 0.5mL tin chloride that radioactive concentration is 2GBq / mL[ 113 Sn] aqueous solution, add 5mL, 3M hydrochloric acid aqueous solution, add 2mL liquid bromine aqueous solution with a mass concentration of 99%, and then use 5M hydrochloric acid aqueous solution to adjust the radioactivity concentration to 185MBq / mL;

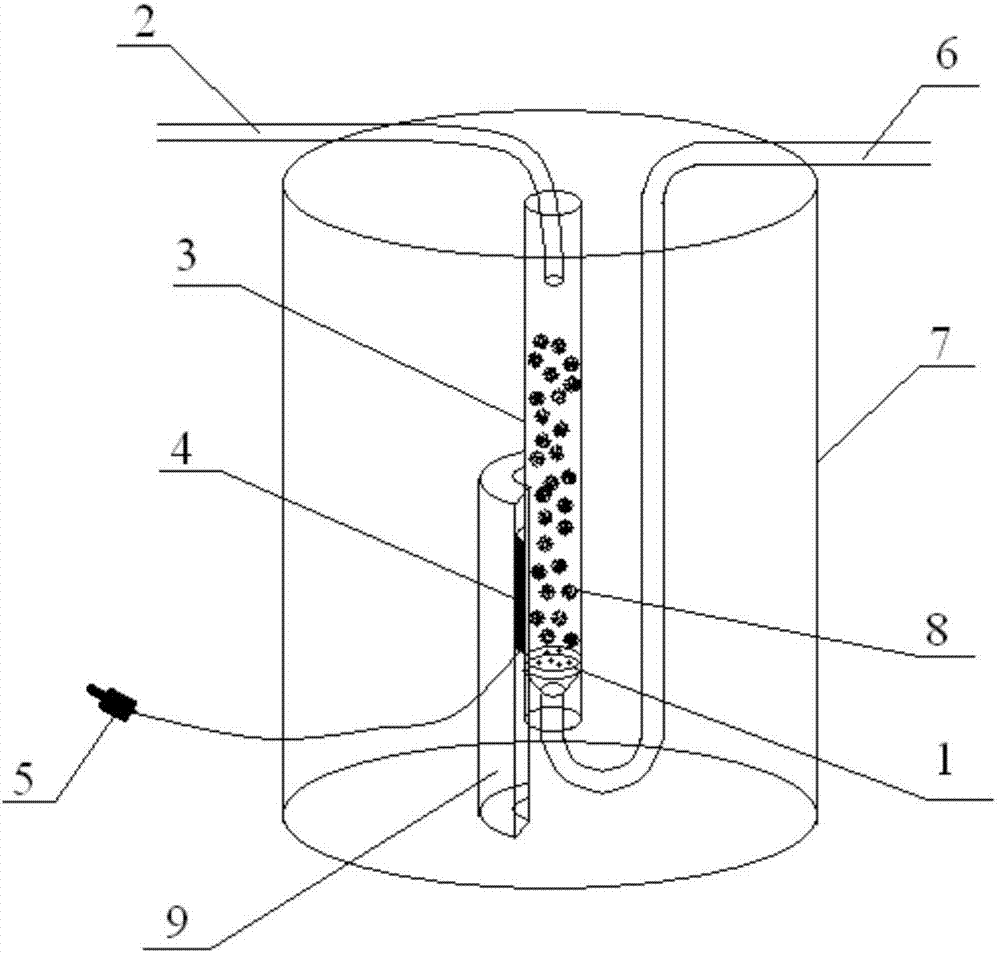

[0026] 2) A support frame 9 is set in the lead protection tank 7, and the support frame is connected with the heating sheet 4; the heating sheet 4 is connected with the power plug 5;

[0027] 3) Get a glass separation column with a diameter of 9 mm and a length of 100 mm, set a sieve plate 1 at the bottom of the glass separation column, put 1 mm thick glass wool on the sieve plate 1, and then put 5 g of nano-sized zirconia particles 8 into the nano-oxidized The particle diameter of the zirconium particle is 10nm, vibrating w...

Embodiment 2

[0031] A kind of preparation method of Sn-113 / In-113m generator, comprises the steps:

[0032] 1) In the container, add pH = 0.5, a volume of 1 mL tin chloride with a radioactive concentration of 1.85 GBq / mL [ 113Sn] aqueous solution, add 1mL, 6M sulfuric acid aqueous solution, add 1.5mL mass concentration 99% liquid bromine aqueous solution, then use 1M sulfuric acid aqueous solution to adjust the radioactive concentration to 185MBq / mL;

[0033] 2) A support frame 9 is set in the lead protection tank 7, and the support frame is connected with the heating sheet 4; the heating sheet 4 is connected with the power plug 5;

[0034] 3) Get a glass separation column with a diameter of 6mm and a length of 140mm, set a sieve plate 1 at the bottom of the glass separation column, put 1mm thick glass wool on the sieve plate 1, and then put 6g of nano zirconia particles, nano zirconia The particle size of the microparticles is 20nm, vibrating while feeding, one end of the liquid inlet pi...

Embodiment 3

[0038] A kind of preparation method of Sn-113 / In-113m generator, comprises the steps:

[0039] 1) In the container, put pH=2, volume is 1mL the tin chloride that radioactive concentration is 3.7GBq / mL[ 113 Sn] aqueous solution, add 6mL, 1M nitric acid aqueous solution, add 2.5mL liquid bromine aqueous solution with a mass concentration of 99%, and then use 1M nitric acid aqueous solution to adjust the radioactive concentration to 370MBq / mL;

[0040] 2) A support frame 9 is set in the lead protection tank 7, and the support frame is connected with the heating sheet 4; the heating sheet 4 is connected with the power plug 5;

[0041] 3) Take a glass separation column with a diameter of 9mm and a length of 100mm, set a sieve plate 1 at the bottom of the glass separation column, put 1mm thick glass wool on the sieve plate 1, then put 5g of nano zirconia particles, nano zirconia The particle diameter of the microparticles is 10nm, vibrating while feeding, one end of the liquid inle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com