Apparatus for testing response speed of sensor, and test method thereof

A technology of response speed and sensor to be tested, which is applied to the construction details of measuring devices, gas analyzers, instruments, etc., can solve the problem of difficulty in obtaining response speed in milliseconds or microseconds, inability to accurately characterize the real performance of devices, and test systems Problems such as inability to be used universally achieve the effect of novel test methods, improved scope of use, and clear principles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

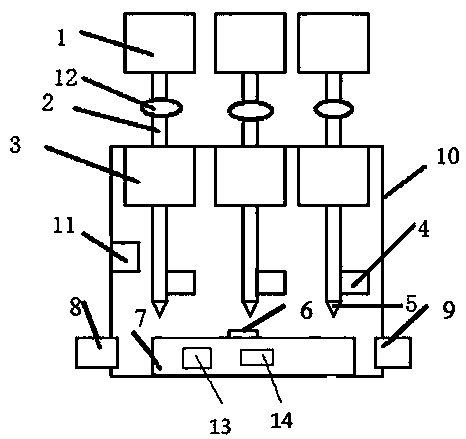

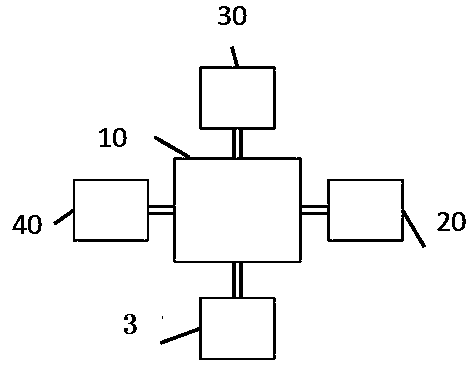

[0023] Such as figure 1 As shown, a device for testing the response speed of a sensor includes three sets of air intake mechanisms, a test cavity, an air intake channel, and an exhaust mechanism. The air intake channels and exhaust mechanisms are respectively located on both sides of the test cavity. A reference sensor is provided in the test chamber, a sample holder is provided at the bottom, a temperature regulator, a position regulator and a sensor to be tested are provided on the sample holder; an air inlet extending into the test chamber is provided above the sample holder mechanism, the air intake structure includes an air supply tank, an air guide tube, a valve 2, an air guide tube azimuth adjustment mechanism, a valve 1 and a nozzle, and the air supply tank communicates with the valve 2, valve 1 and nozzle in sequence through the air guide tube The airway azimuth adjustment structure, valve 1 and nozzle are all in the test chamber, and the airway azimuth adjustment mec...

Embodiment 2

[0025] A test method for a device for testing the response speed of a sensor includes the following steps: Step 1, using software to simulate the size of the nozzle, the relative position of the nozzle and the sensor to be tested, and the switching speed of the valve 1, that is, analyze the pressure at the nozzle according to the fluid mechanics method Uniformity, so as to determine the size of the nozzle, the relative position of the nozzle and the sensor to be tested, and the switching speed of valve 1; step 2, connect all test signals; prepare to test the target gas and background gas, according to the analysis, select a nozzle with a suitable size and shape, and the size of the nozzle should be It is larger than the size of the sensitive surface of the sensor to be tested to ensure that the ejected gas can cover the entire sensing surface area; step 3, the background gas is introduced into the test cavity from the air inlet channel until the background gas is distributed sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com