A kind of production technology of hot-melt type instant black tea powder

A production process and technology for black tea powder, applied in the field of production technology of hot-dissolving instant black tea powder, can solve the problems of difficulty in realizing industrialization and large-scale production, time limitation of production, etc., and achieve a small footprint and save energy consumption. , the effect of reducing the loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

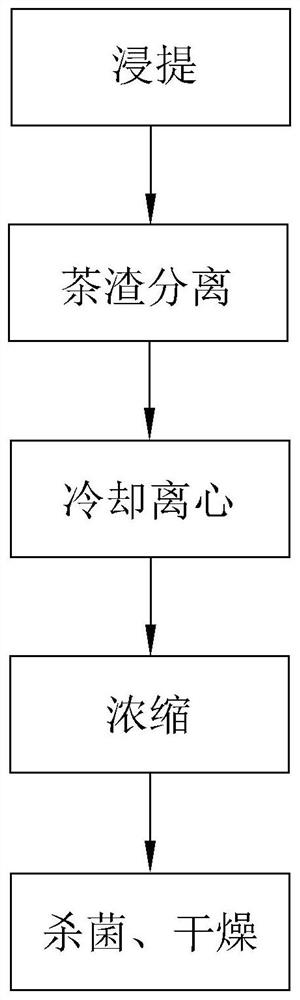

[0047] Example 1: A heat-dissolving quick-soluble red tea powder production process, such as figure 1 As shown, including the following steps to obtain:

[0048] Step 1, leaching: In deionized water at a temperature of 85 ° C, red blouse is added to deionized water according to the ratio of the weight of the deionized water and the redden tea, and 13 min, mix 13 min, and obtain tea soup;

[0049] Step 2, the slag separation: The first filtration process is performed using the horizontal helical pusher settling centrifuge, the rotation speed is 2700 rpm, and the time the filtration process is 3 min, and the rude filtrate is obtained;

[0050] Step three, cooling centrifugation: Cooling the crude filtrate obtained in step II to 65 ° C, after the secondary filtration treatment, the rotation speed of the secondary filtration is 5500 rpm, and the secondary filtration is passed for 3 min, and the clear liquid is obtained;

[0051] Step four, concentrated: concentrate the clear liquid ob...

Embodiment 2

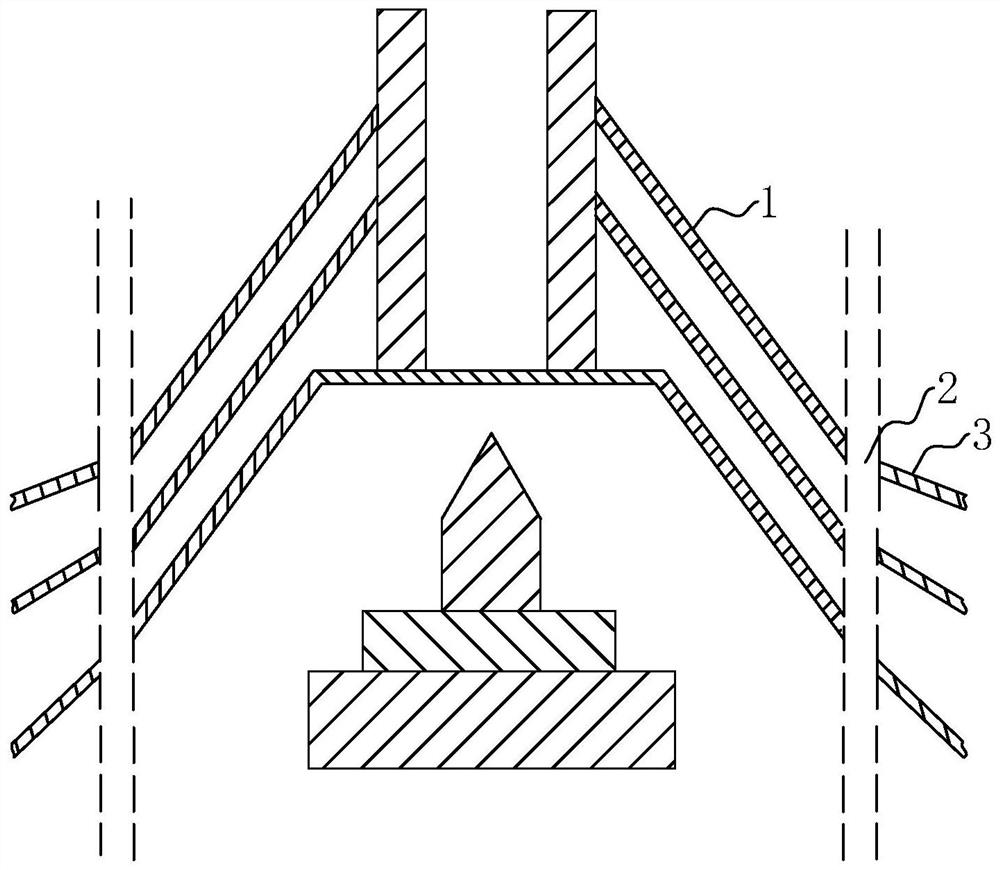

[0054] Example 2: A production process of thermally soluble red tea powder, the difference from Example 1 is that in the disc separator used in step three, such as figure 2 As shown, including the multilayer annular disc 1, the through hole 2 is disposed on the disc 1, and the edge of the disc 1 is folded upward, and the vertical spacing between adjacent loop 3 is greater than. The vertical spacing between adjacent disc 1 is 150-175 ° between the ring sheet 3 and the outer surface of the disc 1.

Embodiment 3

[0055] Example 3: A heat dissolved velockel powder production process, the difference from Example 1 is that the temperature of the deionized water is 85 ° C, the weight of the reddenated tea added and deionized water added. The ratio is 10: 1, mixed for 10 min.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com