Walnut fixing device suitable for oriented extruding

A fixing device and walnut technology, which is applied to a walnut fixing device, a fixing device whose position remains unchanged during processing and extrusion, keeps walnuts in the conveying field, and can solve the problem of high skin damage rate of walnuts, low shell breaking efficiency, and impact on walnuts. Shell breaking efficiency, walnut kernel integrity rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

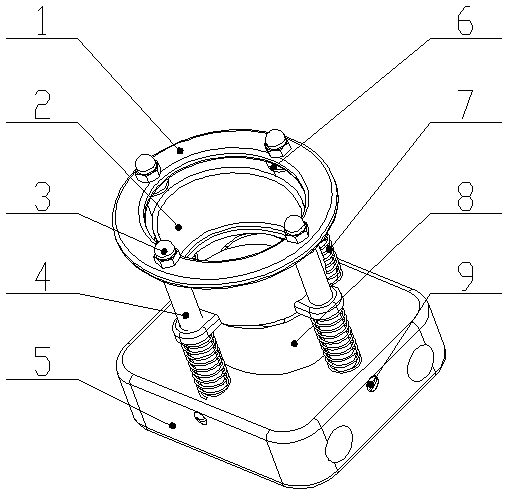

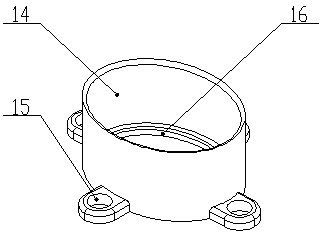

[0018] A walnut fixing device suitable for directional extrusion consists of nine parts: a protective ring (1), a fixing sleeve (2), four cap nuts (3), four slide bars (4), and a base ( 5), four flat washers (6), four compression springs (7), one pressing head (8), and four sliding rod extrusion screws (9).

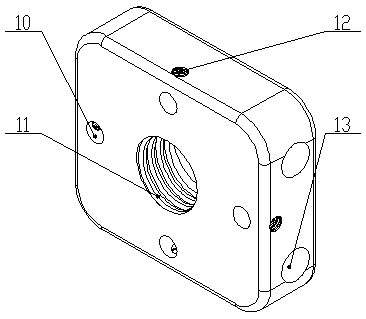

[0019] Such as figure 1 As shown, the center of the base (5) has a lower pressure head installation hole (11) with a thread on the inner side. The lower pressure head installation hole (11) is not a through hole, and the lower end of the lower pressure head (8) is connected to the lower pressure head through a threaded connection. Hole (11) fits, is installed on the base (5). When the walnut was moved down under pressure, the walnut contacted with the pressing head (8) to squeeze the walnut.

[0020] Such as figure 1 As shown, the base (5) also has four slide bar positioning holes (10) and four slide bar pressing holes (12), the slide bar positioning holes (10) are not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com