Tissue and manufacturing method and application thereof

A technology for paper towels and uses, which is applied in the field of paper towels and paper towel preparation, can solve the problems of not easy to degrade, slow to solve, unfavorable to environmental protection, etc., and achieve the effect of easy to degrade, high wet strength, and protect the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

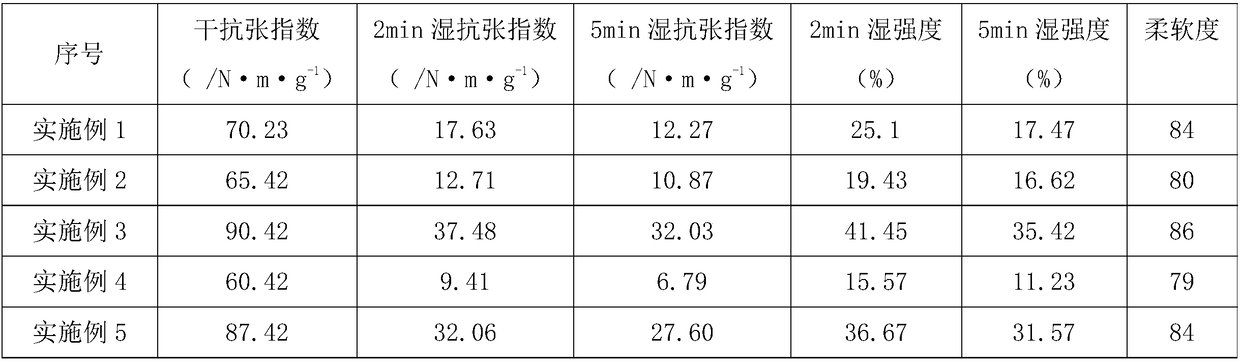

Examples

Embodiment 1

[0026] Embodiment 1 wet strength is high, is easy to degrade, and the preparation technology of environment-friendly novel paper towel

[0027] (1) 65 parts of leaf wood fibers, 35 parts of bamboo fibers are prepared into long-fiber wood pulp, 50 parts of hardwood fibers, 20 parts of straw fibers, and 30 parts of bagasse fibers are prepared into short-fiber wood pulp;

[0028] (2) In the long-fiber wood pulp pulper, add water to adjust the wood pulp concentration to be 6.0wt%, and after disintegrating for 10 minutes, after the obtained pulping material is disentangled by the fiber disintegrator, it is beaten by a beater, and The fibers are cut and divided into filaments to obtain tapped long-fiber wood pulp, the degree of beating is 35°SR, and the length of long fibers of the tapped long-fiber wood pulp is controlled at 1.5-2 mm;

[0029] (3) In the short-fiber wood pulp pulper, add water to adjust the wood pulp concentration to be 6.0wt%, and after 10 minutes of disintegratio...

Embodiment 2

[0032] Embodiment 2 The wet strength is high, easy to degrade, and the preparation process parameter adjustment of environmentally friendly new paper towels (1) 65 parts of leaf wood fibers and 35 parts of bamboo fibers are prepared into long-fiber wood pulp, 50 parts of hardwood fibers and 20 parts of rice straw fibers 30 parts of bagasse fibers are prepared into short-fiber wood pulp;

[0033](2) In the long-fiber wood pulp pulper, add water to adjust the wood pulp concentration to be 6.0wt%, and after disintegrating for 10 minutes, after the obtained pulping material is disentangled by the fiber disintegrator, it is beaten by a beater, and The fibers are cut and divided into filaments to obtain tapped long-fiber wood pulp, the beating degree of which is 35°SR, and the length of long fibers of the tapped long-fiber wood pulp is controlled at 2.5-3.0mm;

[0034] (3) In the short-fiber wood pulp pulper, add water to adjust the wood pulp concentration to be 6.0wt%, and after 10...

Embodiment 3

[0037] Example 3 Adjustment of preparation process parameters of new paper towels with high wet strength, easy degradation and environmental friendliness

[0038] The preparation method of Example 1 is adopted, wherein the composition ratio of the mixed pulp is adjusted as follows: the content of long-fiber wood pulp is 83.5wt%, the content of short-fiber wood pulp is 15.75wt%, and the content of wet strength agent is 0.75wt%. The agent is dialdehyde starch and chitosan, and its ratio is 1:2, wherein, the length of the long fiber is controlled at 2.5-3.0mm, and the length of the short fiber is controlled at 0.5-0.75mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com