A kind of preparation technology of porcelain tooth

A preparation process, technology of porcelain teeth, applied in the direction of dentures, etc., can solve the problems of porcelain teeth easy to collapse, achieve the effect of reducing the collapse of porcelain, reducing the possibility, and reducing the probability of porcelain collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

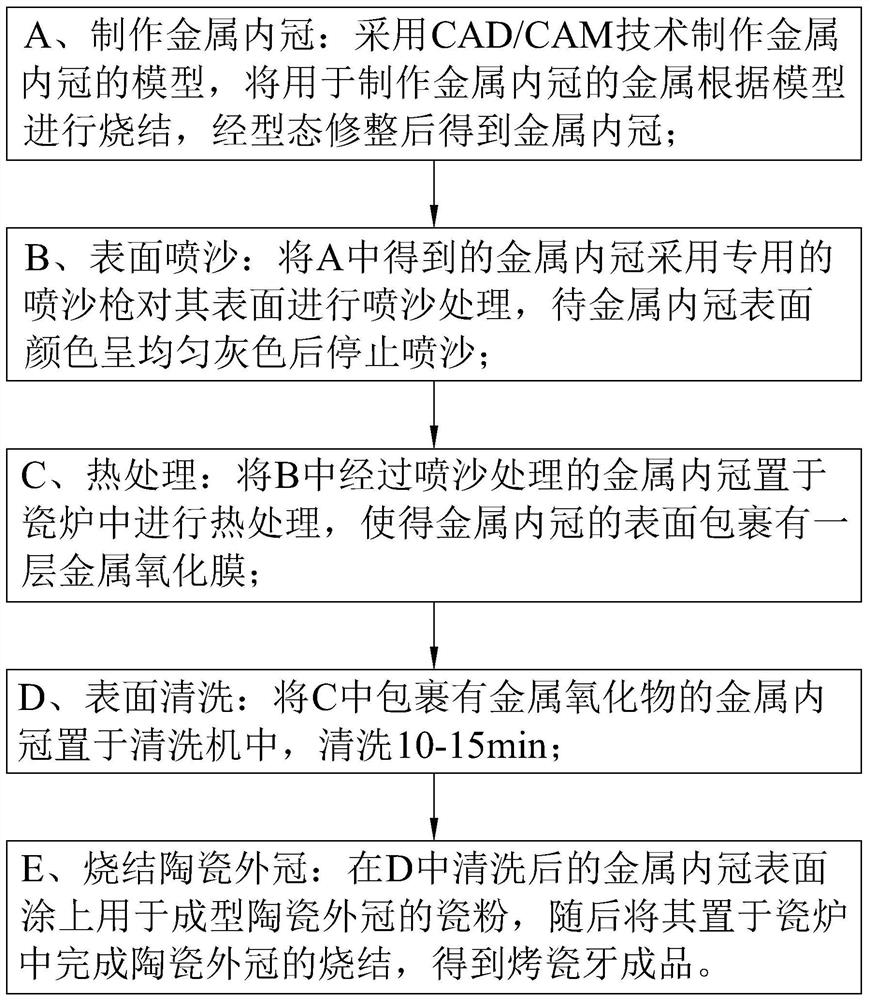

[0047] A preparation process for porcelain teeth, comprising the following steps:

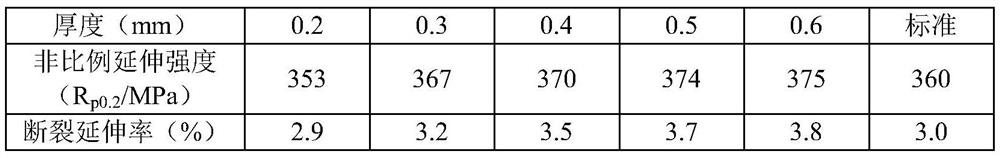

[0048] A. Making the metal inner crown: use CAD / CAM technology to make the model of the metal inner crown, in which the thickness of the metal inner crown is controlled to 0.5mm, and the platinum powder used to make the metal inner crown is sintered and melted in a crucible, and then melted The platinum is pressed and formed according to the designed model; then the sintered and formed platinum is trimmed using a grinding machine with a rotation speed of 30,000r / min and a consistent grinding direction to obtain a metal inner crown;

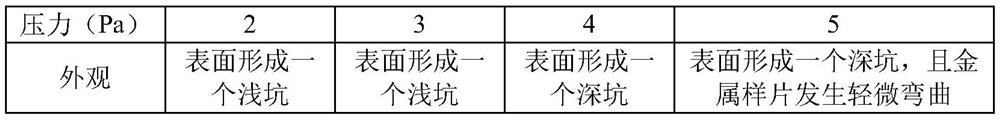

[0049] B. Surface sandblasting: The surface of the metal inner crown obtained in A is sandblasted with a dental sandblasting gun, and the sandblasting pressure of the sandblasting gun is 3Pa during sandblasting, and the sandblasting head is inclined at 45°. Stop sandblasting when the surface color of the metal inner crown is uniform gray;

[0050] C. Heat treatmen...

Embodiment 2- Embodiment 7

[0054] Embodiment 2-embodiment 7 adjusts the condition of heat treatment on the basis of embodiment 1, and concrete adjustment situation is as shown in the table below:

[0055]

Embodiment 8

[0057] The difference from Example 1 is that in this example, during heat treatment, hydrogen peroxide is sprayed from top to bottom on the surface of the metal coping through a high temperature resistant nozzle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com